Accelerated characterization method for long-term creep property of rigid foam

A rigid foam, creep performance technology, applied in the direction of strength characteristics, the use of stable tension/pressure test material strength, instruments, etc., can solve the problems of small characterization time range, many errors, etc., to achieve a small number of material test pieces , the effect of a wide time range and flexible test methods

Pending Publication Date: 2021-07-20

NANJING UNIV OF SCI & TECH

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide an accelerated characterization method for the long-term creep performance of rigid foam, to solve the existing method for accelerating the characterization of long-term creep properties of materials, TTSP and SSM exist when the characterization time is long, the required materials Too many errors caused by too many test pieces and the problem of small characterization time range

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

[0065] Obtaining creep master curves for typical viscoelastic materials

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

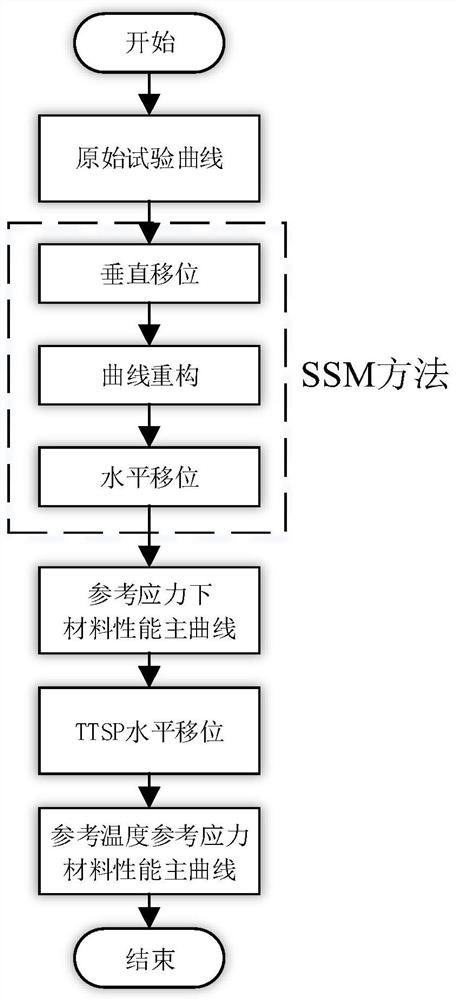

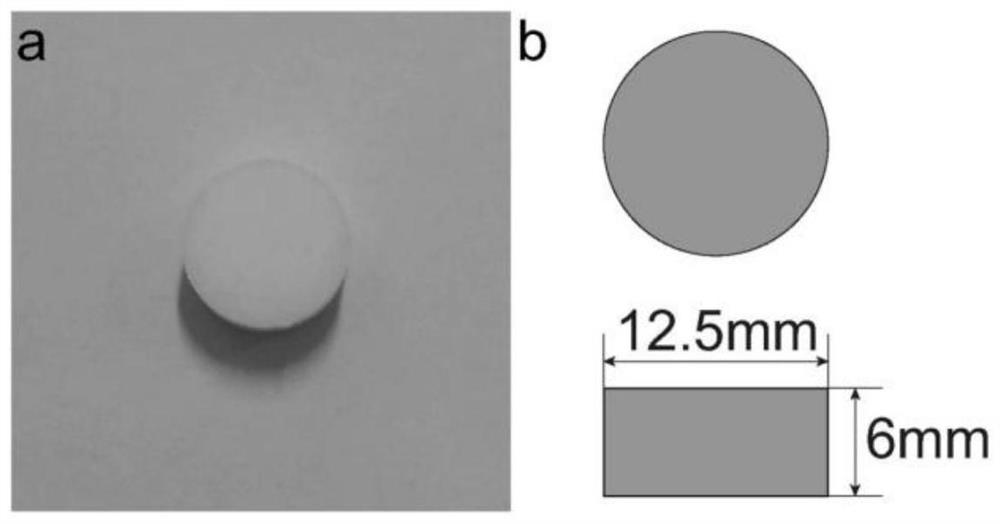

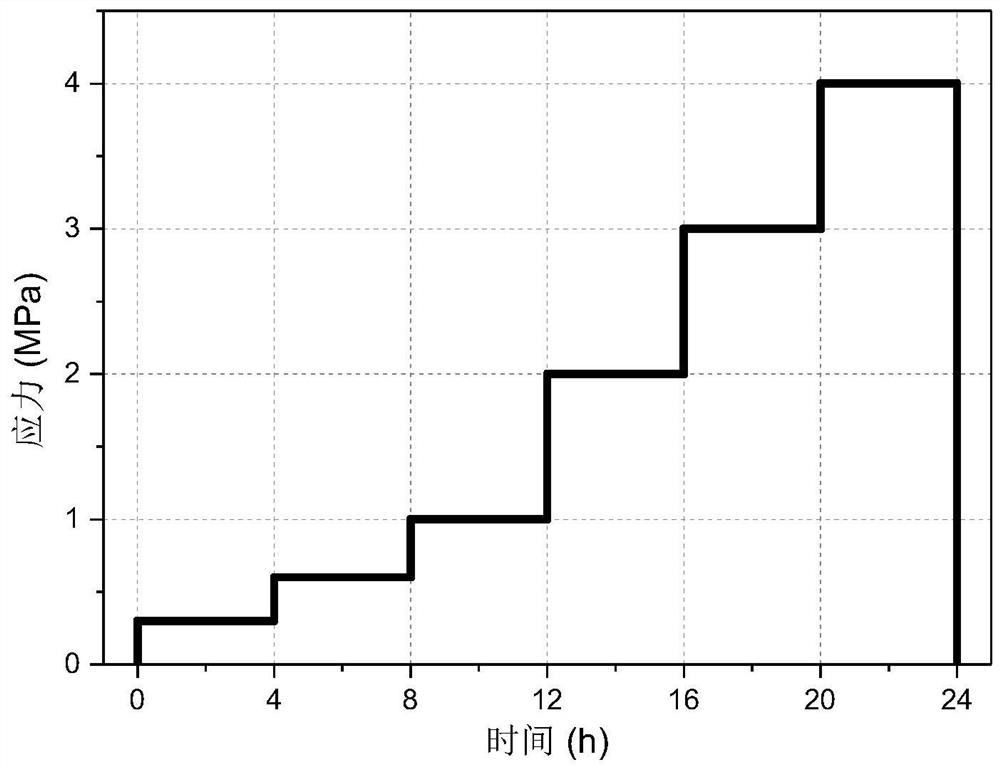

The invention provides an accelerated characterization method for the long-term creep property of rigid foam, which is characterized in that a creep curve of a PMI (polymethacrylimide) material under different temperatures and load conditions is obtained on the basis of step-by-step loading creep tests carried out on the PMI material at four temperatures. A grading equal stress method is combined with a time-temperature equivalence principle to form a grading equal stress-time temperature equivalence method; the creep property main curve of the PMI material is constructed, and the accelerated characterization of the long-term creep property of the PMI material is realized. According to the method, a main curve under reference stress and temperature is constructed in a manner of raising temperature and load and shifting along a logarithmic time axis by applying an equivalence principle in a creep property mechanical test which is originally time-consuming. The time span represented by the main curve can be extended to several or even dozens of orders of magnitude of the test duration, so that the test time is greatly shortened.

Description

technical field [0001] The invention belongs to the research field of creep properties of elastoplastic materials, in particular to an accelerated characterization method for long-term creep properties of rigid foam. Background technique [0002] Polymethyl methacrylate (PMI) and other materials have been widely used in many fields due to their good cushioning and vibration reduction performance, high specific strength, high specific stiffness, performance design and easy processing and molding. Different from the mechanical properties of traditional elastic-plastic materials, such materials often exhibit viscoelastic mechanical properties at room temperature, that is, their mechanical parameters are time-, temperature-, stress-, and strain-rate dependent. Under the premise that the rigidity meets the design requirements, the failure mode of this type of viscoelastic material is mostly due to the weakening of mechanical properties or even damage and fracture caused by creep ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/08G16C60/00

CPCG01N3/08G16C60/00G01N2203/0003G01N2203/0019G01N2203/0071G01N2203/0075

Inventor 杨春浩张鹏马吴宁仲健林张震东

Owner NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com