Direct shear tester for testing strength of slip band and direct shear test method

A direct shear tester, strength testing technology, applied in strength characteristics, using stable shear force to test material strength, instruments, etc., can solve limited shear distance, difficult residual strength test, shear surface shear stress and uneven strain distribution to achieve continuity and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

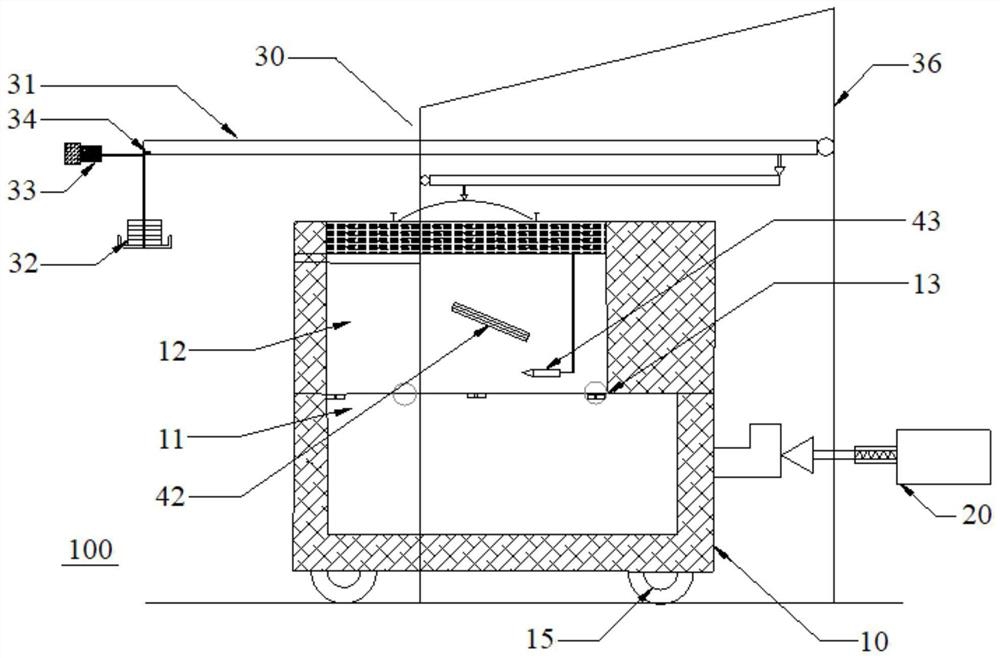

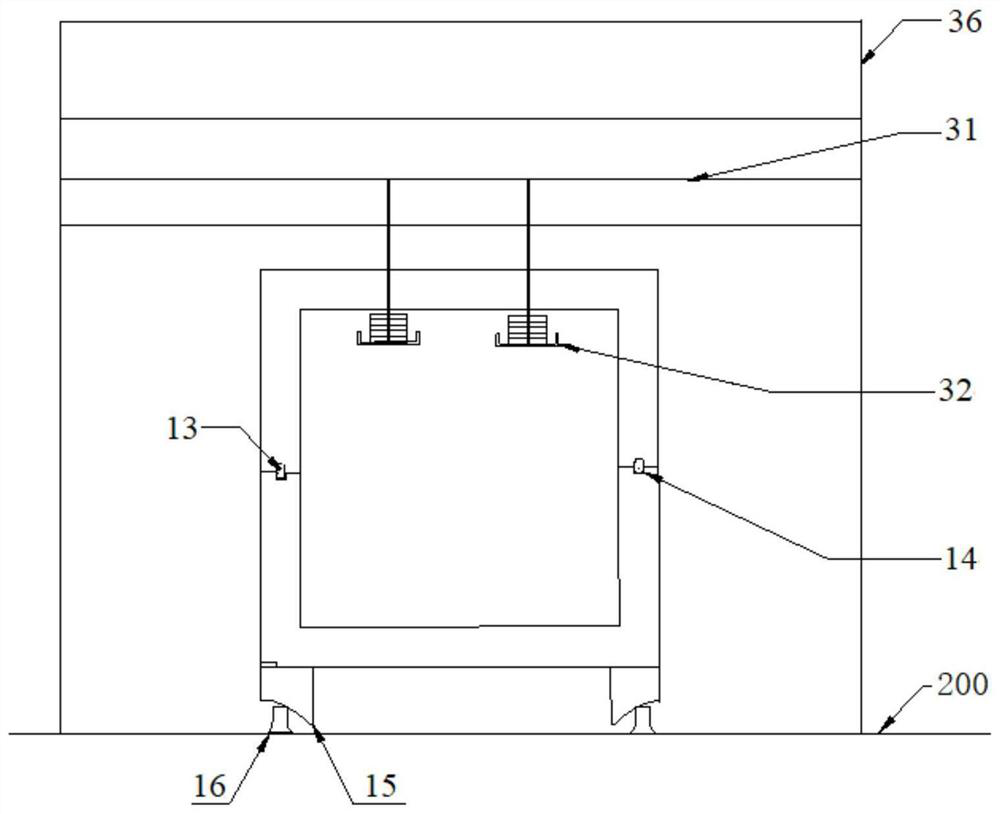

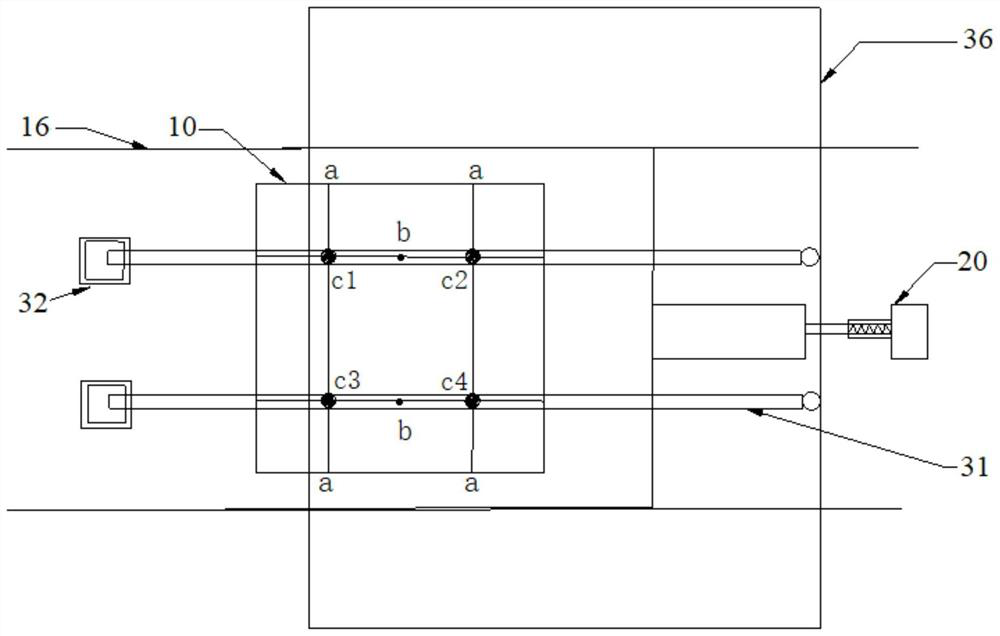

[0045] An embodiment of the present invention provides a sliding belt strength testing direct shear tester 100, which can be used for testing the strength of sliding belts of various structures. see Figure 1 to Figure 3 , the sliding belt strength testing direct shear tester 100 includes a shear box 10, a horizontal loading system 20, a normal loading system 30 and a measurement system. Wherein the shearing box 10 comprises a lower shearing box 11 and an upper shearing box 12, there is a shear seam between the lower shearing box 11 and the upper shearing box 12, and the opening area of the lower shearing box 11 is greater than the upper shearing box The opening area of 12; the horizontal loading system 20 and the normal loading system 30 respectively act on the lower shear box 11 and the upper shear box 12 to carry out horizontal loading and normal loading respectively; the measurement system is used to obtain the Test data, including but not limited to horizontal stress...

Embodiment 2

[0067] Based on the same inventive concept, this embodiment provides a direct shear test method for testing the strength of a sliding belt, which is implemented based on the direct shear tester 100 for testing the strength of a sliding belt in the first embodiment. In this embodiment, the sliding belt in the form of gravel soil-bedrock structure is used as the test object, and the sliding surface of the gravel soil-bedrock sliding belt is the gravel soil-bedrock interface. see Figure 9 , the method specifically includes the following steps:

[0068] S1: Put the gravel soil-bedrock original sample in the shear box 10, adjust the normal position of the gravel soil-bedrock original sample, so that the gravel soil-bedrock original sample - The bedrock interface is flush with the top surface of the lower shear box 11 .

[0069] Specifically, push the shear box 10 out of the normal loading system 30 as a whole along the guide rail 16, and put in the shear box 10 the gravel soil-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com