Equipment and method for low-temperature methanol double washing based on heat exchange and modified methanol

A heat exchange, low-temperature methanol technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of reducing volume circulation, high equipment operating costs, low acid gas concentration, etc., to optimize methanol circulation. , The effect of reducing entrainment loss and improving gas purification

Pending Publication Date: 2021-07-23

灵谷化工集团有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, in order to ensure the absorption capacity of methanol to acid gas and reduce the volume circulation, it is necessary to maintain the methanol washing device to operate at low temperatu

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

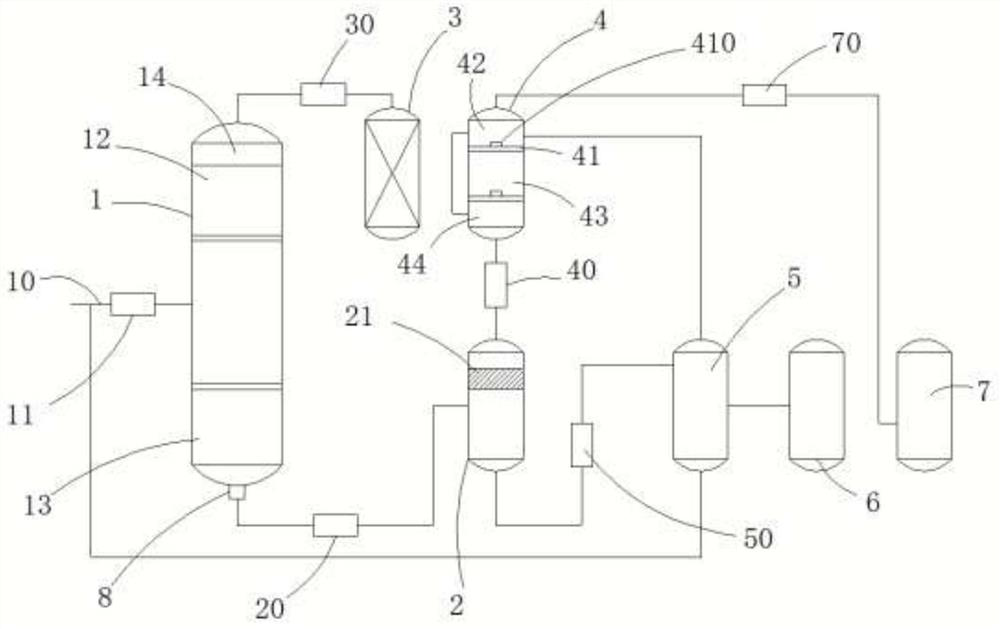

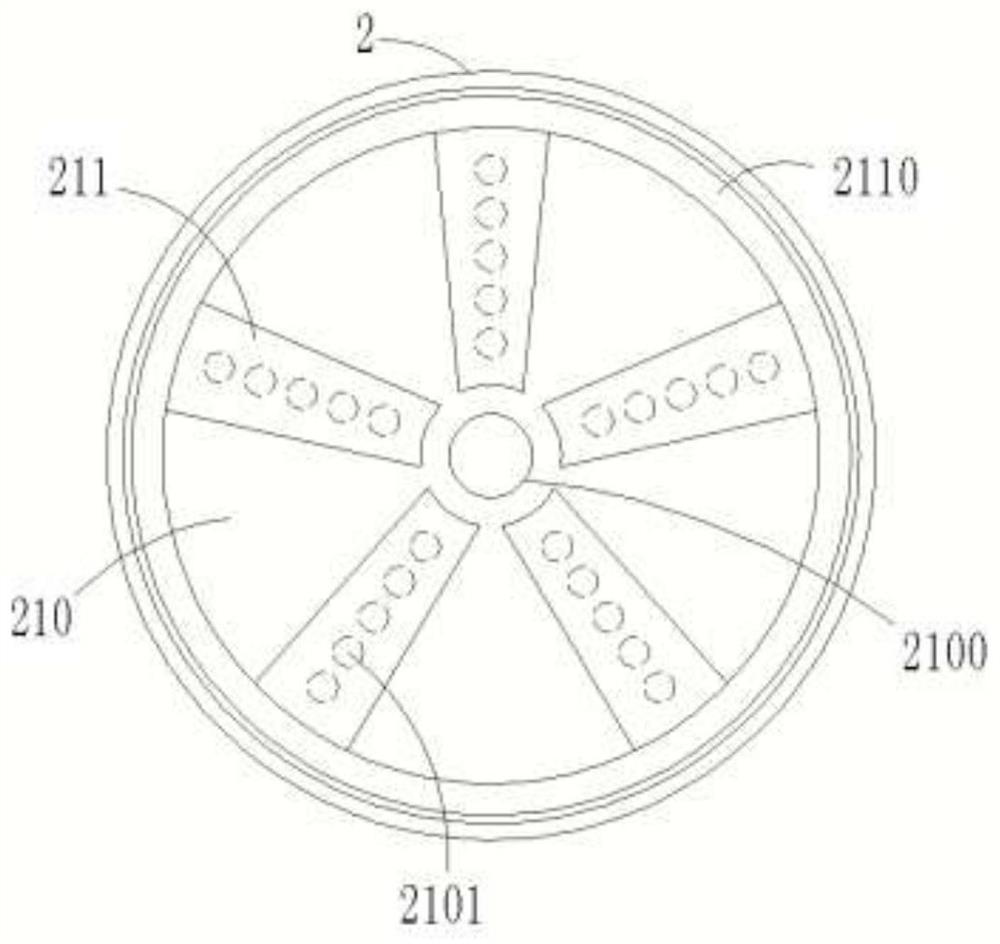

The invention discloses equipment for low-temperature methanol double washing based on heat exchange and modified methanol. The equipment comprises a process gas absorption tower, a flash tower, a CO2 desorption tower, an H2S concentration tower, a methanol regeneration tower, a methanol-water separation tower and a tail gas water washing tower; the flash tower and the CO2 desorption tower are respectively connected with the process gas absorption tower, the H2S concentration tower and the methanol regeneration tower are respectively connected with the flash tower, the methanol-water separation tower is connected with the methanol regeneration tower, and the tail gas washing tower is connected with the H2S concentration tower; CO2 gas and a methanol-rich solution in raw material gas are separated out by utilizing the process gas absorption tower, CO2 gas is resolved out by utilizing the CO2 desportion tower, H2S gas in the methanol-rich solution is flashed out by utilizing the flash tower, a methanol-poor solution after flash evaporation sequentially passes through the methanol regeneration tower and the methanol-water separation tower, and tail gas overflowing from the top of the H2S concentration tower is discharged after being washed by the tail gas washing tower; and the equipment is reasonable in structural design, the methanol consumption is reduced by adjusting the methanol recycling process, and the production cost is saved.

Description

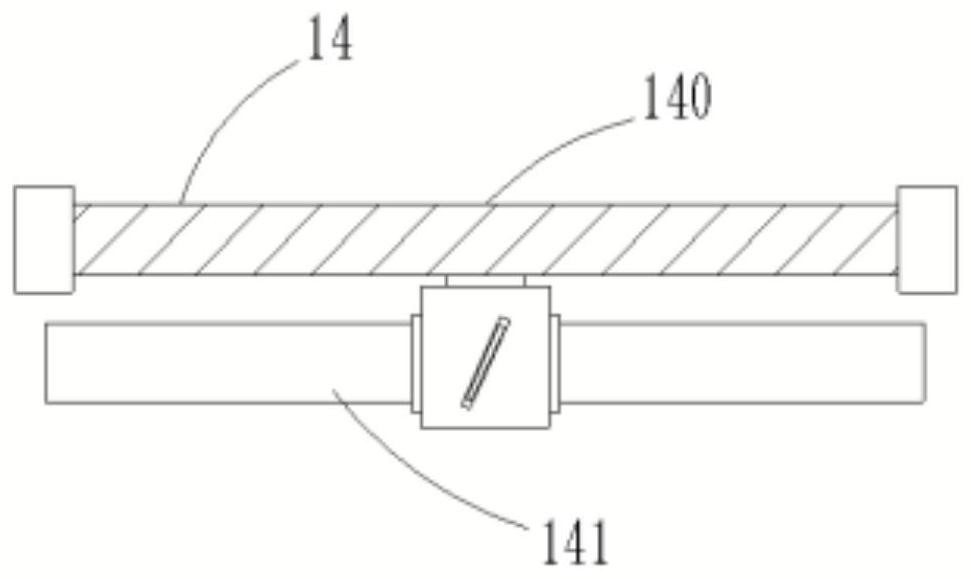

technical field [0001] The invention relates to the technical field of low-temperature methanol washing, in particular to a device and method for low-temperature methanol double washing based on heat exchange and modified methanol. Background technique [0002] The low-temperature methanol washing process is a purification process that uses physical absorption to separate the shift gas. 2 、H 2 S and carbonyl sulfide and other acid gases have a good absorption effect, and the gas is completely dried. At the same time, the acid gases are classified and recovered during the methanol regeneration process. At present, the low-temperature methanol washing process is widely used in chemical fields such as coal-to-synthetic ammonia and coal-to-methanol. Its technology is mature, the gas purification degree is high, and the regenerated methanol meets the production requirements. [0003] Since gas dissolving in liquid is an exothermic process, as the solubility of acid gas in low-t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/18B01D53/14

CPCB01D53/18B01D53/1468B01D53/1475B01D53/1418B01D53/1425B01D53/1493Y02C20/40

Inventor 谈成明钱林明单亚军邱正辉陈辉顾敏丁键许建彬

Owner 灵谷化工集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com