Method and device for transferring gravity separation substances

A technology of gravity separation and transfer, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of difficult liquid level synchronization, large friction resistance of rubber sealing ring seals, inability to descend and ascend normally, etc. Reasonable structure design and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

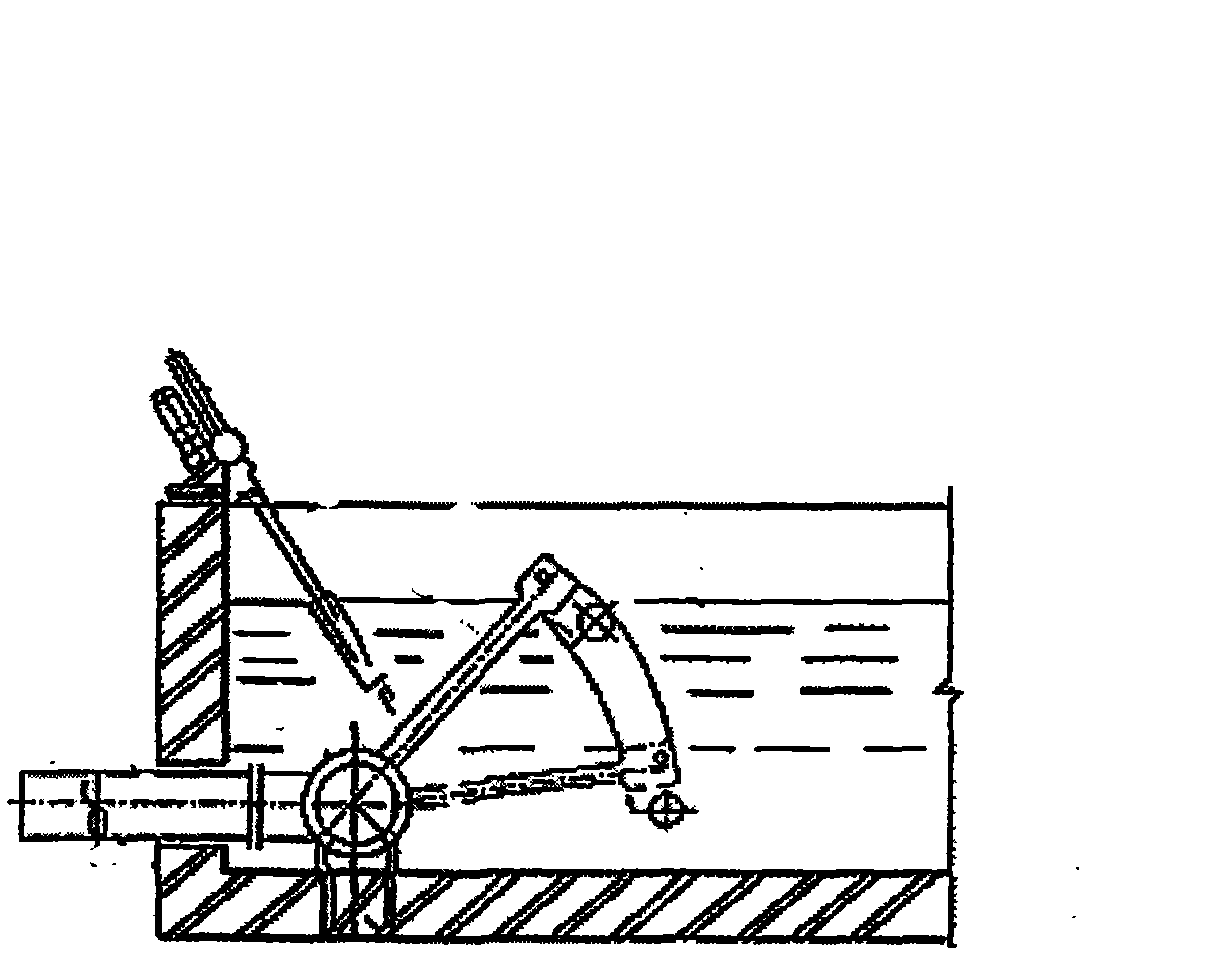

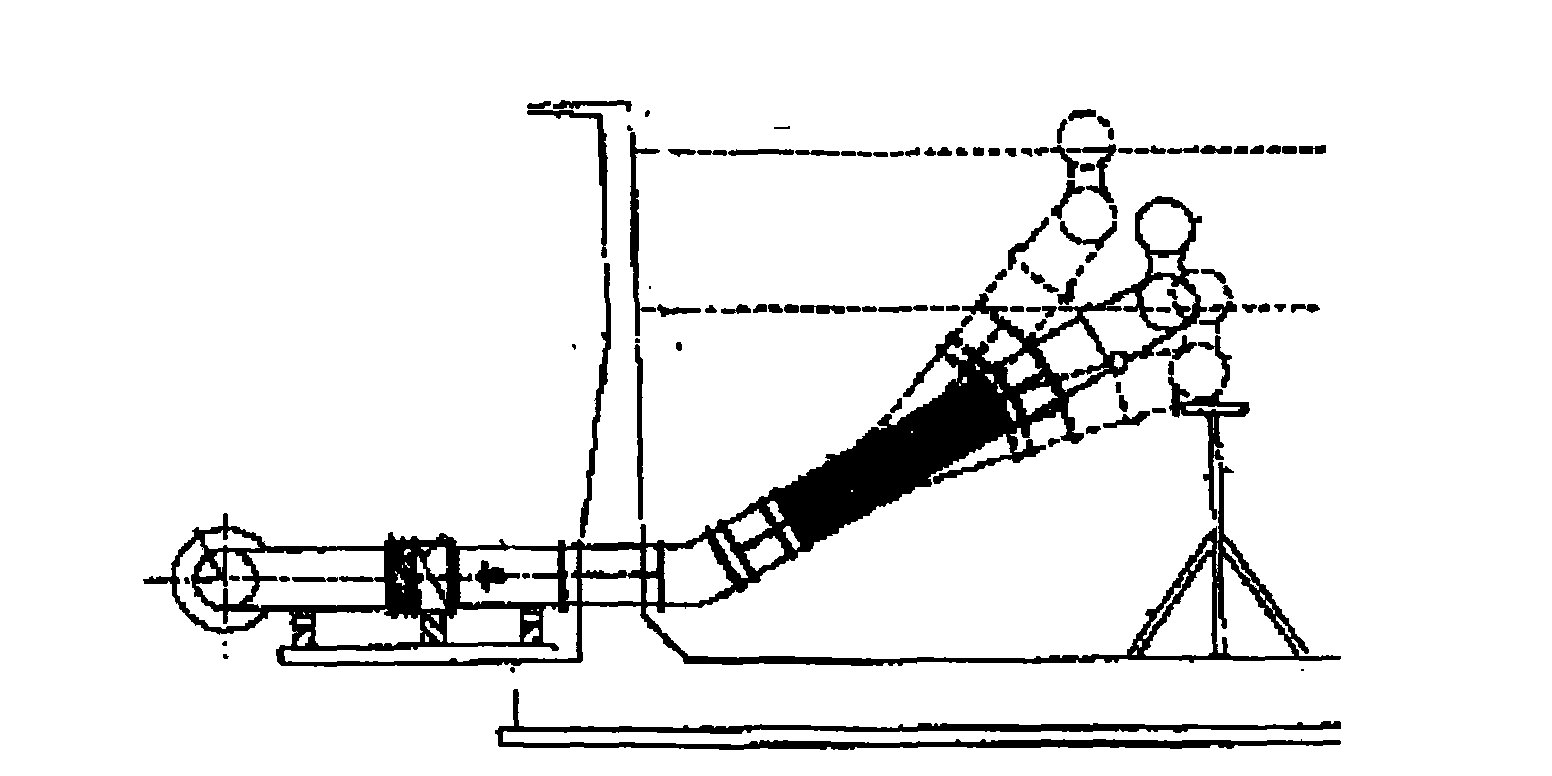

[0043] Such as Figure 5-9The gravity separation removal device shown is mainly composed of a buoy actuator 1, a weir plate 2, and a linear self-supporting telescopic cylinder 3. The weir plate 2 is fixedly set on the outer wall surface of the upper end of the linear self-supporting telescopic cylinder 3, and forms an opening and closing water inlet weir with the bottom surface of the buoy actuator 1. Cylinder 3 consists of three sections of cylinders 3.1, 3.2 and 3.4 with different diameters to form a sliding sleeve type telescopic cylinder, adjacent cylinders can be slid relative to each other in sequence, such as the bottom end of the inner cylinder is equipped with a limit block 3.4, and the outer cylinder is equipped with a slider 3.3, Sealing element 3.5 is set on the outer wall of the joint of the inner and outer cylinders. The length and number of segments of the telescopic cylinder need to be designed according to the drop height of the liquid level. The weir plate ...

Embodiment 2

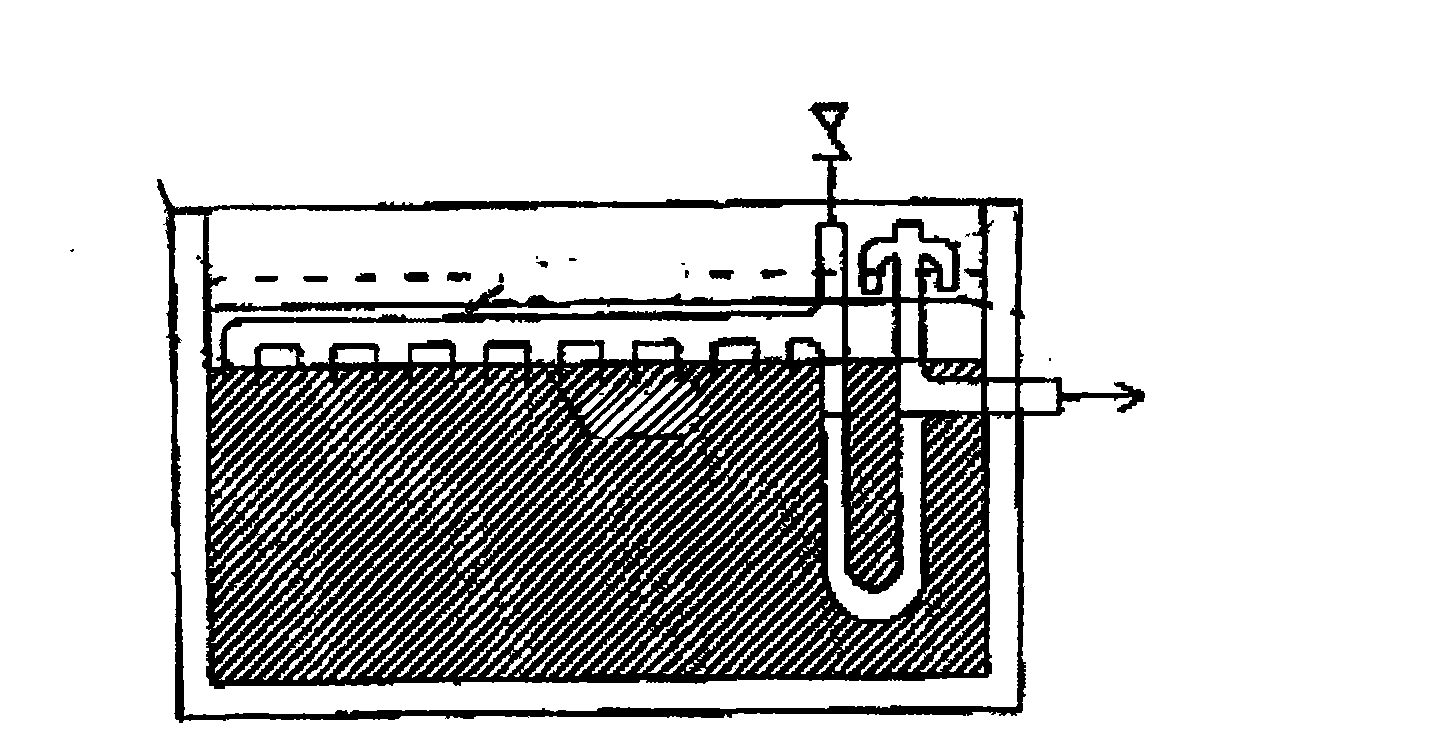

[0045] The device described in Embodiment 1 is adopted to carry out the gravity separation to take, and the specific technological process is as follows Figure 10 Shown: Settling, stratification - weir plate open - device and liquid level fall synchronously - minimum liquid level weir plate closed.

[0046] The first step of sedimentation or clarification: the solution undergoes physical and chemical reactions or biological activities in the sedimentation or clarification structure, and the inlet weir of the pipetting device is closed and kept at the upper limit of the liquid level (such as Figure 11 );

[0047] The second step is to stratify and open the pipetting device: the solution undergoes physical and chemical reactions or biological activities in the sedimentation or clarification structure, and after a certain period of stratification, the pipetting device moves downward and the water inlet weir is opened (such as Figure 12 ), the stratified supernatant slowly ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com