Composite pipe pressing device and method for manufacturing fully-bonded thermoplastic composite pipe through composite pipe pressing device

A compression device and composite pipe technology, which can be applied to other household appliances, applications, household appliances, etc., can solve the problems of inability to adjust the angle, shorten the service life of the composite pipe, and poor bonding ability of the interface between the reinforcement layer and the inner layer. To achieve the effect of reasonable equipment structure design and good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

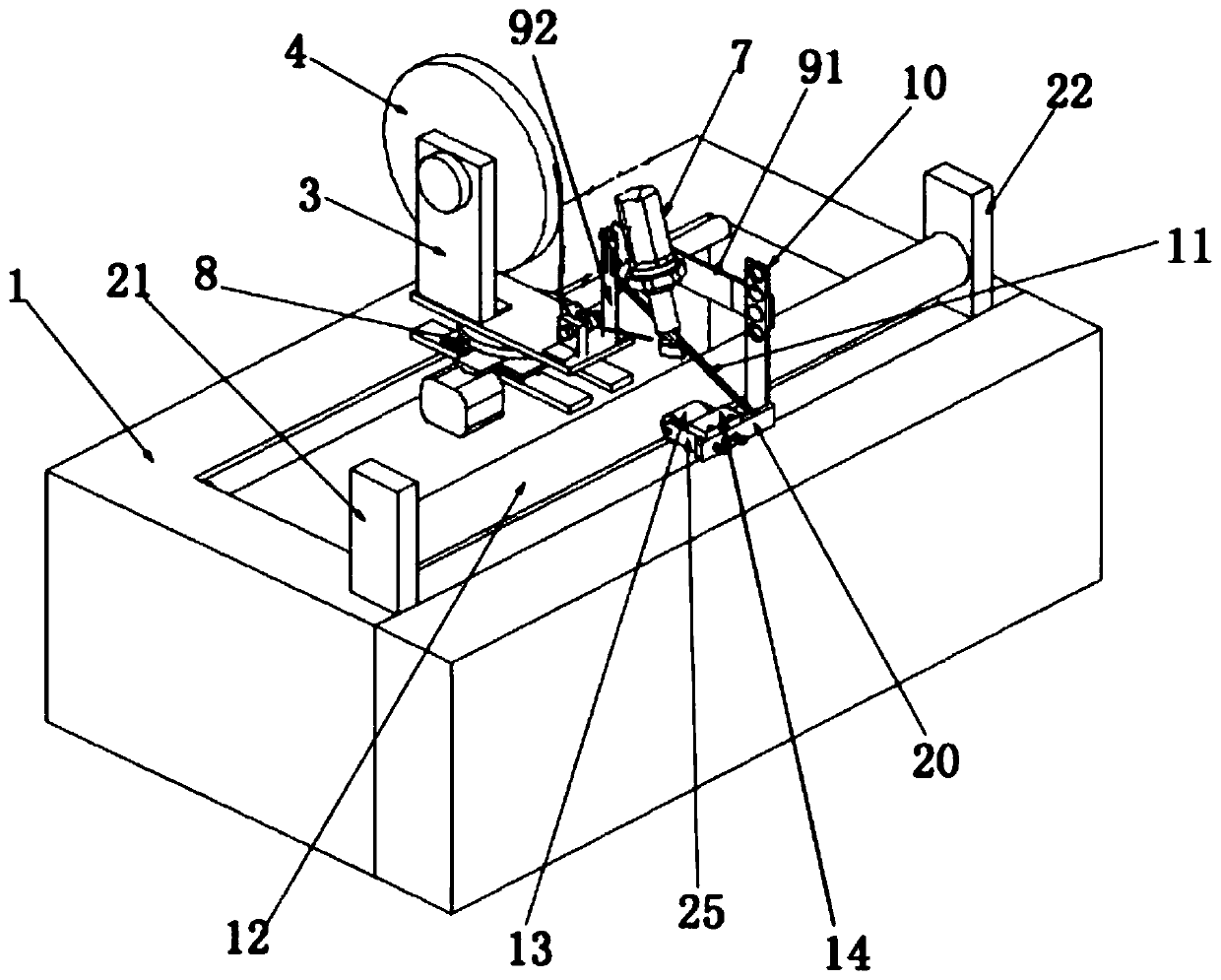

[0031] Example: Control Figure 1~5

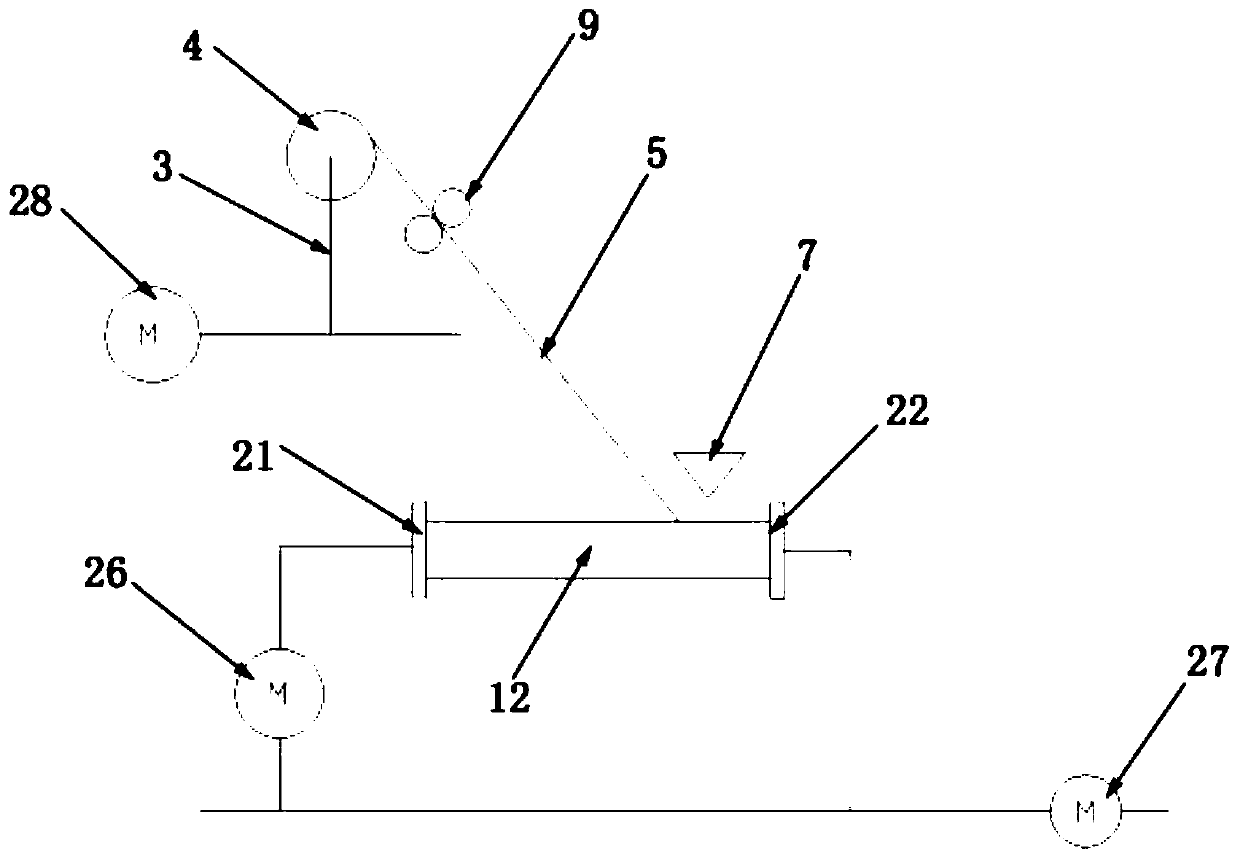

[0032] A composite pipe pressing device includes a frame 1, a pipe placing and winding system arranged on the frame 1, a reel operating table, a heat gun 7 and a pipe pressing system.

[0033] The pipe placing and winding system includes a first motor 26, a left end top plate 21 connected to the first motor 26, a second motor 27, a right end top plate 22 connected to the second motor 27, and a left end top plate 21 and a right end top plate 22 between the pipe lining 12 and the first guide rail arranged under the left end top plate 21 and the right end top plate 22, the second motor 27 can drive the right end top plate 22 to move left and right on the first guide rail, thus It drives the integral movement of the top plate 21 at the left end, the lining layer 12 of the pipe and the top plate 22 at the right end on the first guide rail.

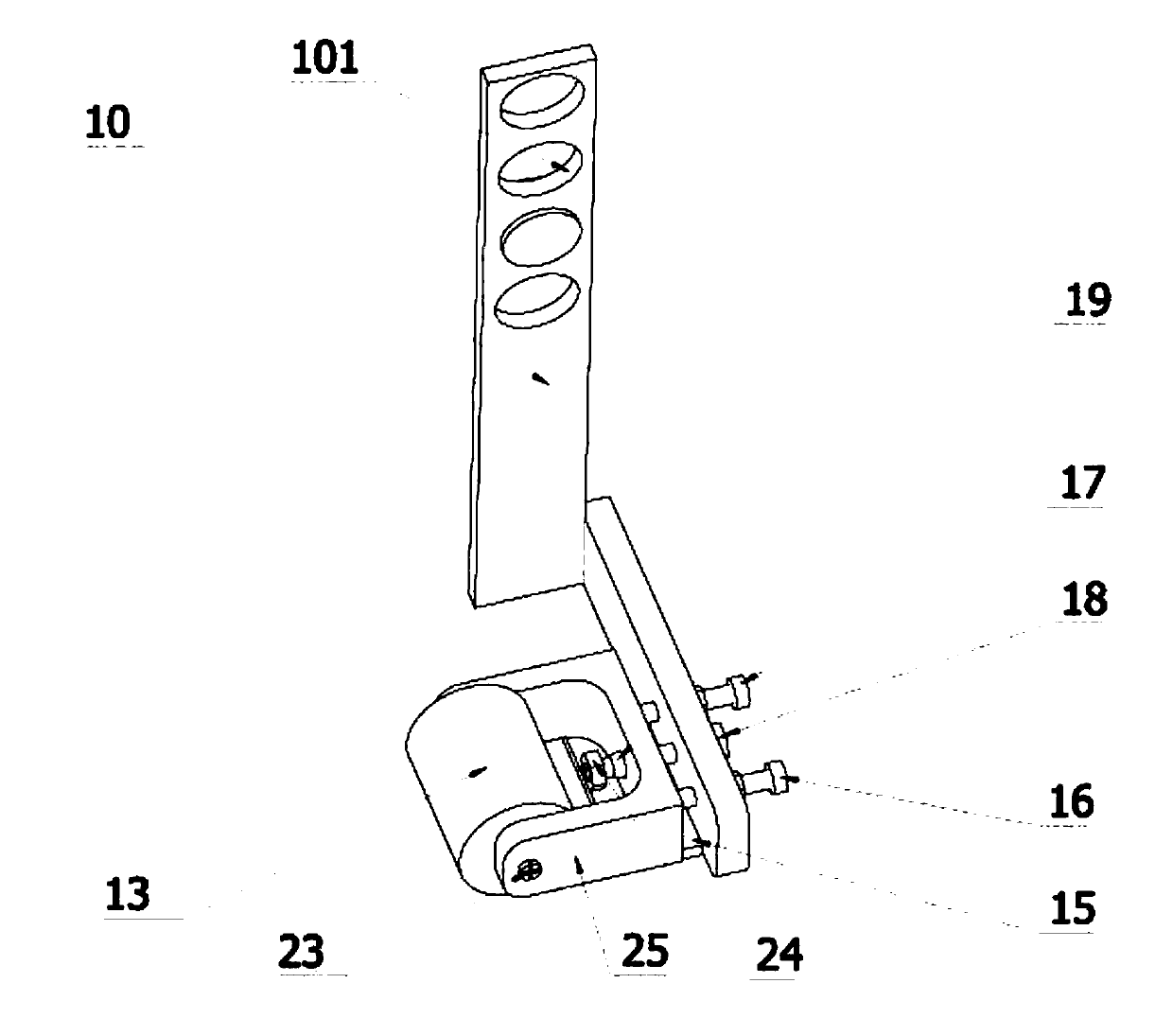

[0034] The pipe pressing system includes a pressing wheel positioning assembly, a support rotating fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com