A liftable pattern for large cylinders

A technology of cylinder body and shape, which is applied in the field of shape with shaping effect, and can solve problems such as difficulty in shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to illustrate the technical solutions of the present invention more clearly, the present invention will be further described in detail below with reference to specific embodiments. Please note that the embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

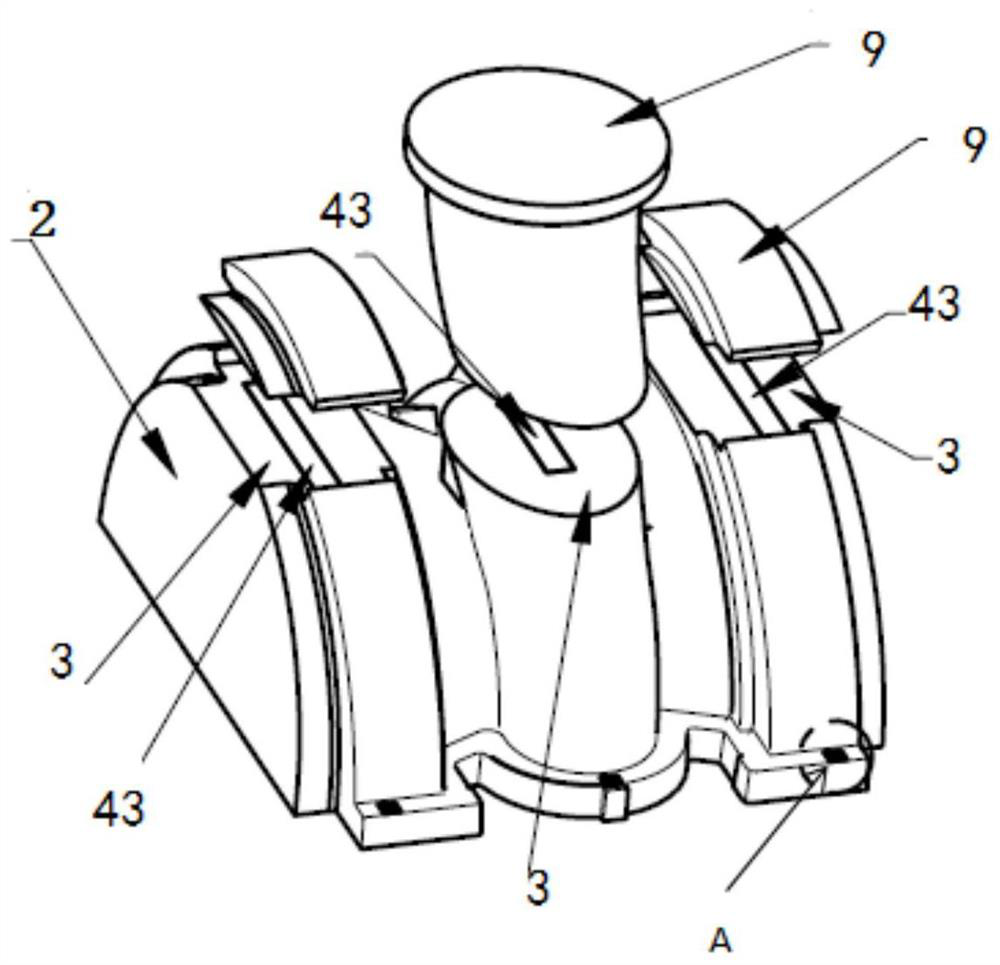

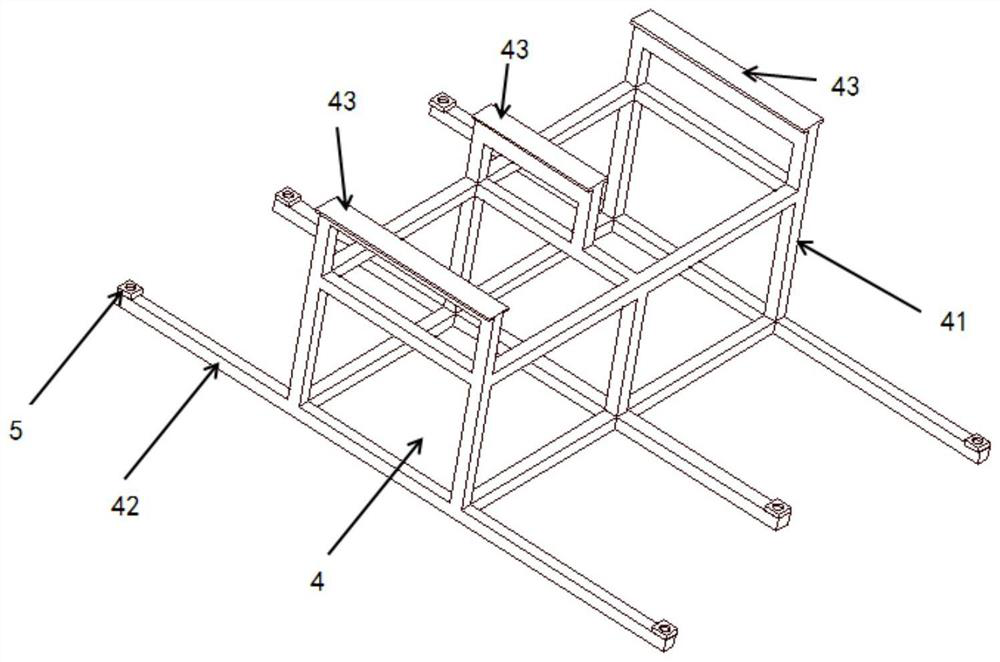

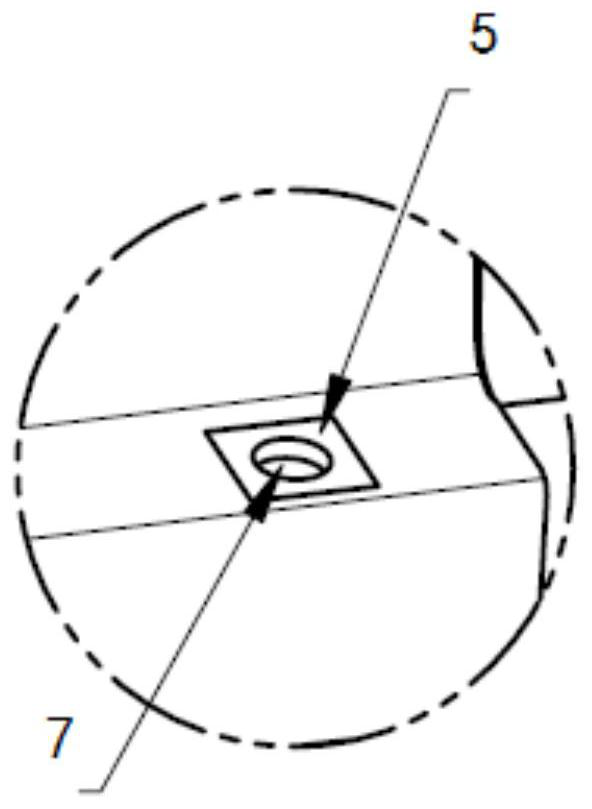

[0028] The pattern in casting refers to the process equipment or consumable parts that simulate the shape of the casting to form the mold cavity; in order to ensure the formation of the cavity that meets the requirements, the pattern should have sufficient strength, rigidity and appropriate surface accuracy and dimensional accuracy. When molding a large cylinder block mold, the large cylinder block is divided into the upper part of the cylinder block, the middle ring of the second cylinder block, the middle ring of the first cylinder block, and the lower part of the cylinder block. The mold is difficult to form, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com