Multi-station milling fixture equipment

A multi-station, milling technology, applied in the direction of metal processing equipment, manufacturing tools, clamping, etc., can solve problems such as uneven force, deformation of the hole wall to the outer surface, etc., to achieve reliable clamping and ensure clamping effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

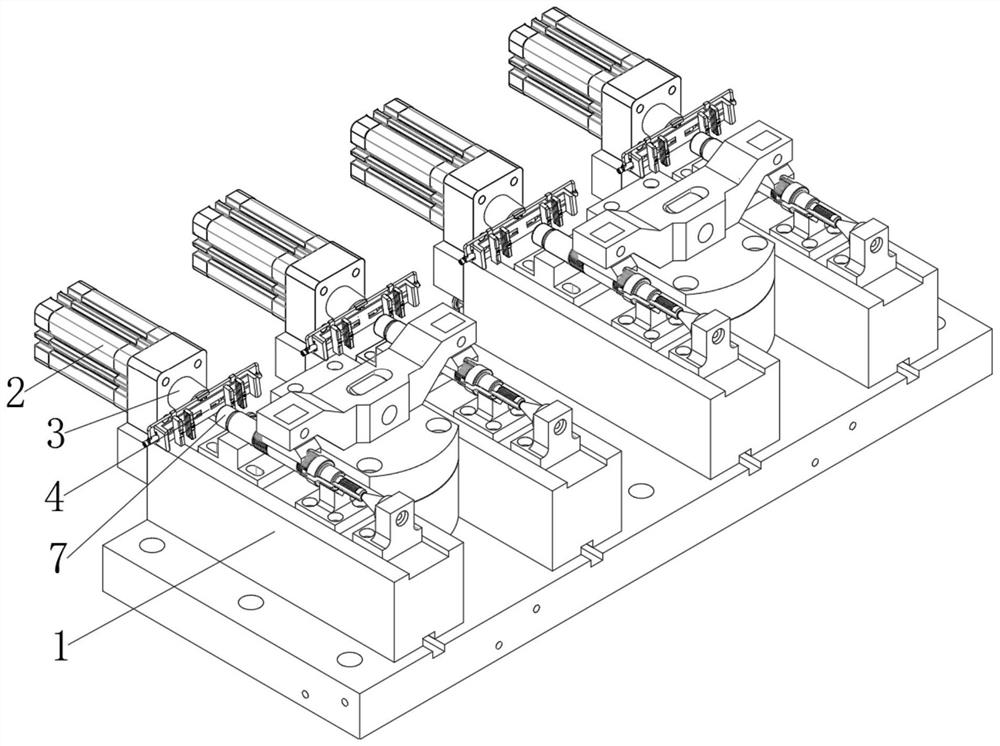

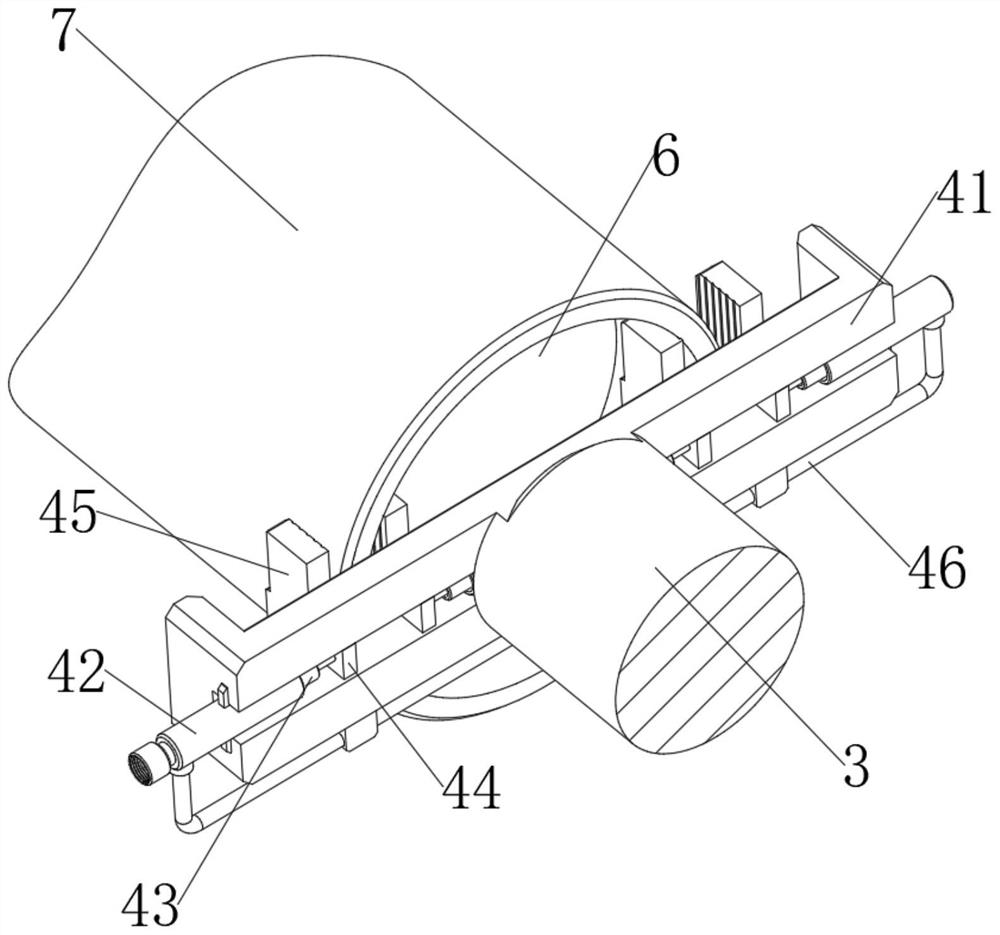

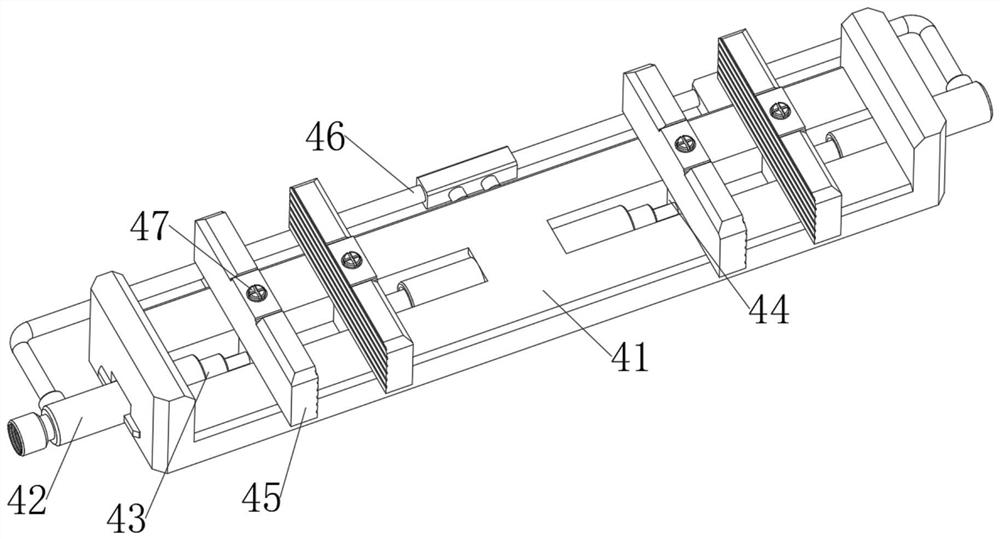

[0028] see Figure 1-3 , a multi-station milling fixture device, including a station seat 1 and an outer cylinder 2 on the station seat 1, a push rod 3 is slidably connected to the outer cylinder 2, and a clamping device 4 is installed on the push rod 3 to clamp Device 4 comprises clamping seat 41, and clamping seat 41 is fixedly installed on the push rod 3, and supporting device 42 is fixedly installed on clamping seat 41, and the inside of supporting device 42 is slidingly connected with pushing device 43, and pushing device 43 is installed with Sliding plate 44, on the sliding plate 44, the clamping plate 45 that is threadedly connected with clamping parts by threaded rod 47;

[0029] The support device 42 includes an outer sleeve 421, the outer sleeve 421 is fixed on the clamping seat 41, the outer sleeve 421 is equipped with a trachea 46, the outer sleeve 421 is provided with a circular hole groove 422, and the trachea 46 communicates with the inside of the circular hole ...

Embodiment 2

[0033] This embodiment is an improvement made on the basis of Embodiment 1. The pushing device 43 includes a shaft 431, the shaft 431 is slidably connected inside the round hole groove 422, and a sliding groove 434 is arranged in the shaft 431. The sliding groove 434 The inside is movably connected with the adjusting device 5, and the sliding groove 434 is also slidably connected with the moving block 433 of the limit adjusting device 5, the block 433 is connected with the shaft rod 431 through the limit spring 8, and the block 433 and the adjusting device 5 are perpendicular to each other. And the clamping block 433 is in conflict with the adjusting device 5 , and the clamping block 433 is in conflict with the inner wall of the round hole groove 422 .

[0034] In this example:

[0035] Reduce springback: According to Figure 4 and Figure 5As shown, the shaft 431 inside the round hole groove 422 is pushed by high-pressure gas, so that the shaft rod 431 slides inside the rou...

Embodiment 3

[0038] This embodiment is an improvement made on the basis of Embodiment 2. The adjustment device 5 includes a telescopic rod 51, which is slidably installed inside the slide groove 434, and the telescopic rod 51 is connected with the slide plate 44. On the telescopic rod 51 A connecting rod 53 is rotatably connected, and the connecting rod 53 is connected with the sliding groove 434 by a compression spring 54. The limit block 52 is also fixedly installed on the telescopic rod 51. The inner wall of the shaft rod 431 is provided with a spiral groove 447, and the shaft rod 431 is also provided with a The vertical groove 446 and the spiral groove 447 are in communication with the vertical groove 446 , and the inside of the outer casing 421 is provided with a chute 423 .

[0039] In this example:

[0040] Precise fixation: according to Figure 4 As shown, although the rebound distance of the shaft rod 431 can be reduced by using Embodiment 2, the problem of rebound is not solved....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com