Clamp for casting machining

A fixture and casting technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to rotate and lift of castings, inability to guarantee accuracy, dimensional deviation, etc., to improve efficiency, wide applicability, improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

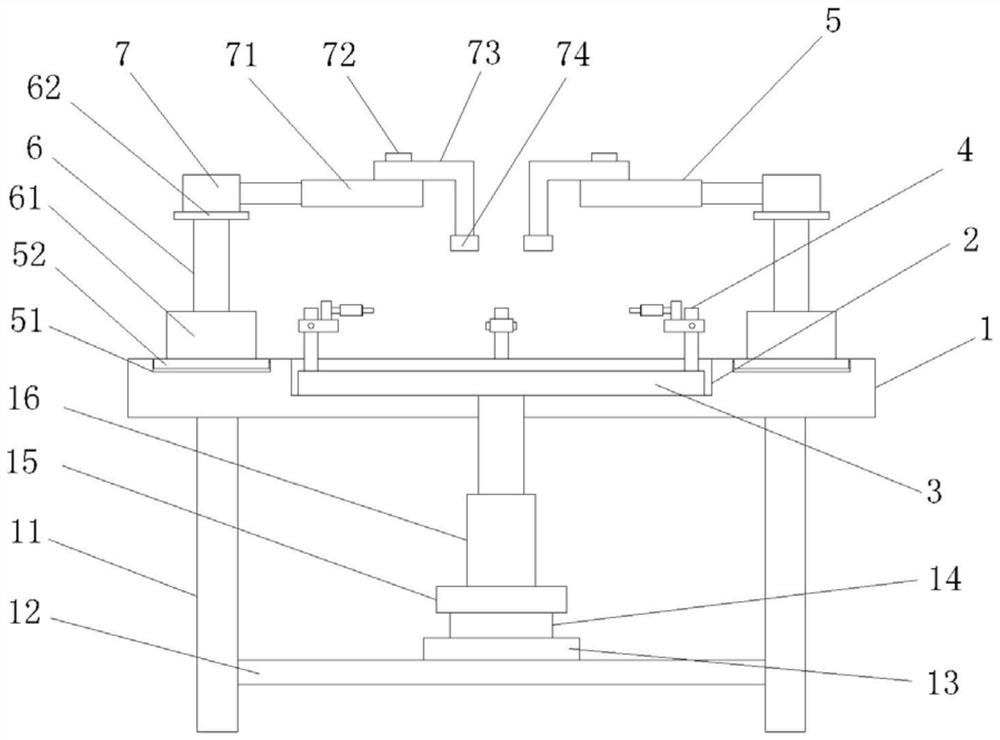

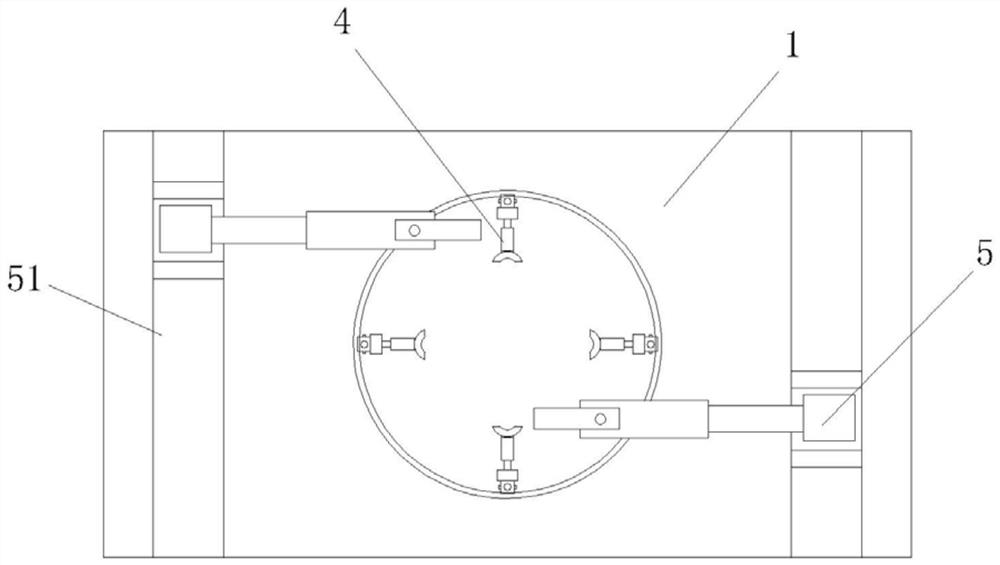

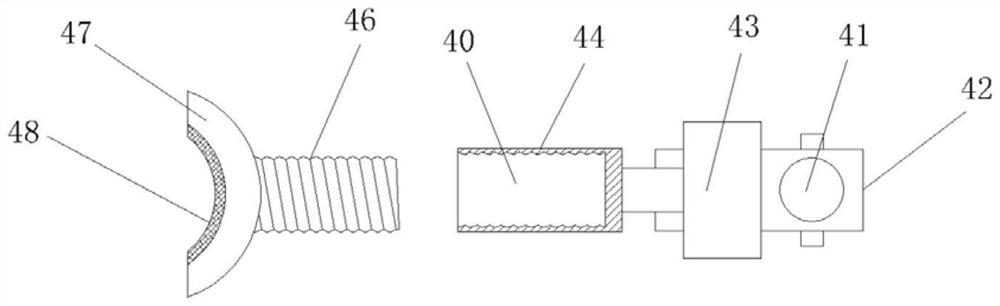

[0018] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention is a fixture for casting processing, including a support table 1, the upper surface of the support table 1 is provided with a downwardly recessed positioning groove 2, a positioning plate 3 is provided in the positioning groove 2, and the support table 1. A number of support feet 11 are provided on the outer side of the bottom. A bottom plate 12 is provided below the support table 1. The bottom plate 12 is connected and fixed to the support feet 11. A fixed plate 13 is provided above the bottom plate 12. The fixed plate 13 A first rotating shaft 14 is arranged above, and a support plate 15 is arranged above the first rotating shaft 14, and an electric push rod 16 is arranged above the support plate 15, and the electric push rod 16 runs through the positioning groove 2. The upper end of the push rod 16 is connected to the bottom of the positioning plate 3, the positioning plate 3 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com