Ceramic tile tapper

A technology for hole saws and ceramic tiles, which can be used in the direction of working accessories, manufacturing tools, grinding drives, etc., and can solve the problems of debris, worker injuries, and easy water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

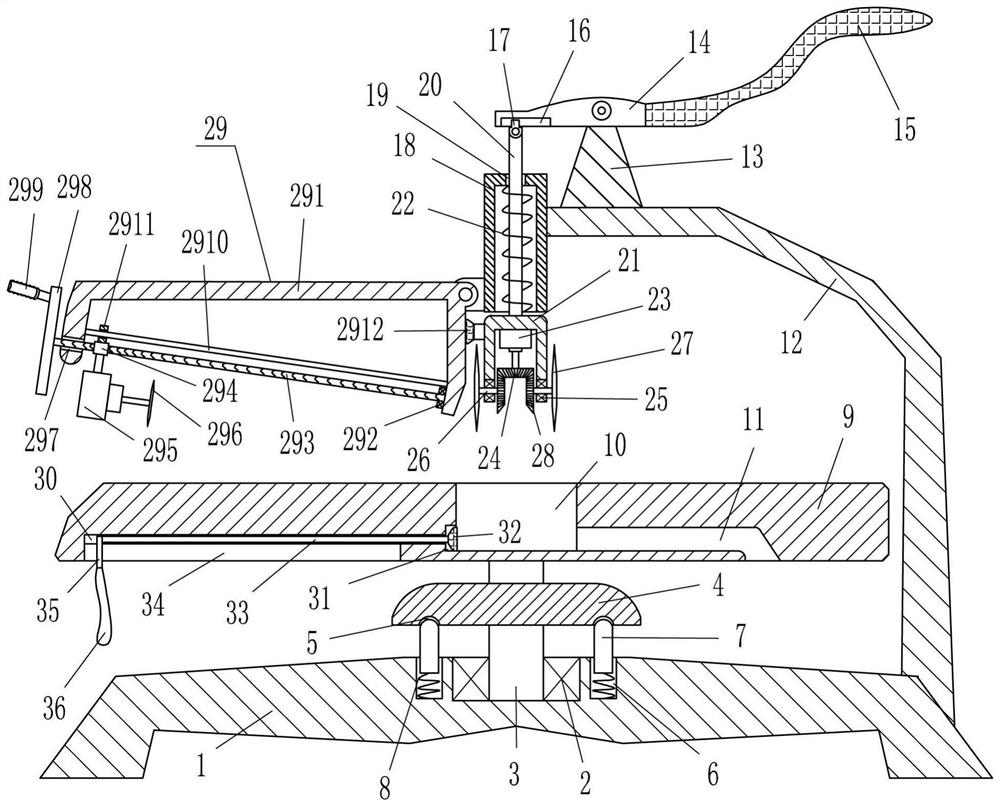

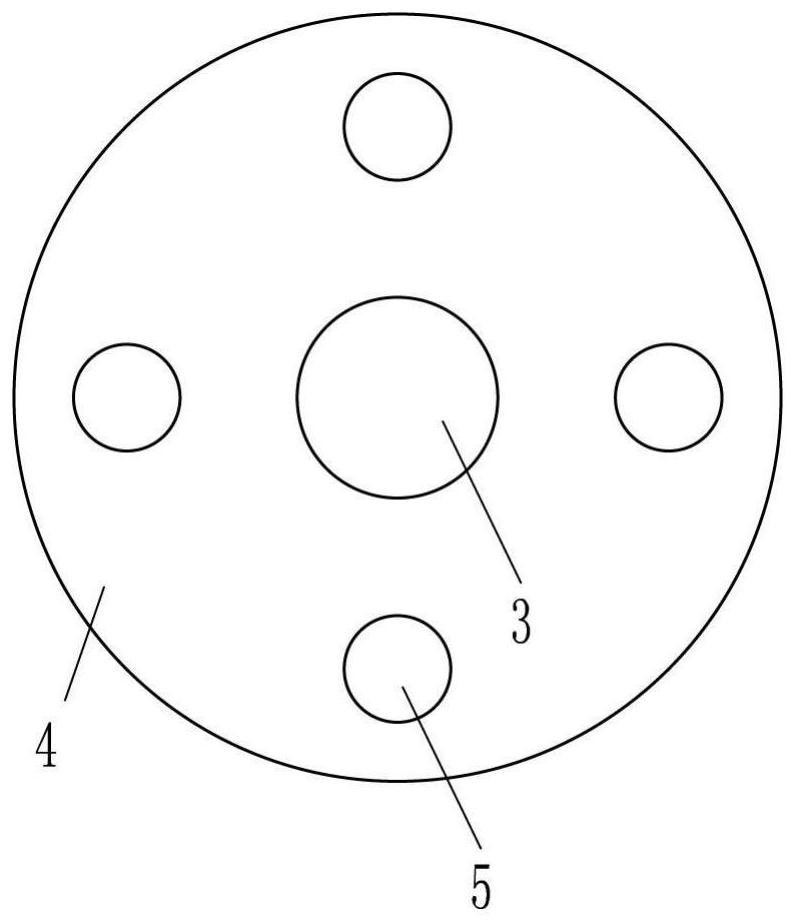

[0016] A tile hole saw such as Figure 1-2 As shown, it includes a base 1, a first bearing seat 2, a first rotating shaft 3, a turntable 4, a clamping rod 7, a first spring 8, a placement plate 9, a 7-shaped plate 12, a support seat 13, a pendulum plate 14, and a handle 15 , slider 17, sleeve 18, movable rod 20, frame body 21, second spring 22, driving motor 23, first bevel gear 24, second bearing seat 25, second rotating shaft 26, cutter 27 and second cone Gear 28, the first bearing seat 2 is installed embedded in the middle of the top of the base 1, the first rotating shaft 3 is installed in the first bearing seat 2, the upper part of the first rotating shaft 3 is equipped with a turntable 4, and the eccentric position of the bottom of the turntable 4 is evenly spaced. There are four arc-shaped grooves 5, a placement plate 9 is installed on the top of the first rotating shaft 3, a vertical groove 10 is provided on the right side of the top of the placement board 9, and a dis...

Embodiment 2

[0018] A tile hole saw such as Figure 1-2As shown, it includes a base 1, a first bearing seat 2, a first rotating shaft 3, a turntable 4, a clamping rod 7, a first spring 8, a placement plate 9, a 7-shaped plate 12, a support seat 13, a pendulum plate 14, and a handle 15 , slider 17, sleeve 18, movable rod 20, frame body 21, second spring 22, driving motor 23, first bevel gear 24, second bearing seat 25, second rotating shaft 26, cutter 27 and second cone Gear 28, the first bearing seat 2 is installed embedded in the middle of the top of the base 1, the first rotating shaft 3 is installed in the first bearing seat 2, the upper part of the first rotating shaft 3 is equipped with a turntable 4, and the eccentric position of the bottom of the turntable 4 is evenly spaced. There are four arc-shaped grooves 5, a placement plate 9 is installed on the top of the first rotating shaft 3, a vertical groove 10 is provided on the right side of the top of the placement board 9, and a disc...

Embodiment 3

[0021] A tile hole saw such as Figure 1-2 As shown, it includes a base 1, a first bearing seat 2, a first rotating shaft 3, a turntable 4, a clamping rod 7, a first spring 8, a placement plate 9, a 7-shaped plate 12, a support seat 13, a pendulum plate 14, and a handle 15 , slider 17, sleeve 18, movable rod 20, frame body 21, second spring 22, driving motor 23, first bevel gear 24, second bearing seat 25, second rotating shaft 26, cutter 27 and second cone Gear 28, the first bearing seat 2 is installed embedded in the middle of the top of the base 1, the first rotating shaft 3 is installed in the first bearing seat 2, the upper part of the first rotating shaft 3 is equipped with a turntable 4, and the eccentric position of the bottom of the turntable 4 is evenly spaced. There are four arc-shaped grooves 5, a placement plate 9 is installed on the top of the first rotating shaft 3, a vertical groove 10 is provided on the right side of the top of the placement board 9, and a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com