Method for calculating holding pressure of telescopic oil cylinder of automatic tensioning system of conveyor chain

A telescopic oil cylinder and pressure-maintaining technology, used in conveyors, underground transportation, conveyor objects, etc., can solve problems such as increased wear, broken chain, affecting the normal operation of equipment, etc., to avoid over-tightening or over-loosening and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

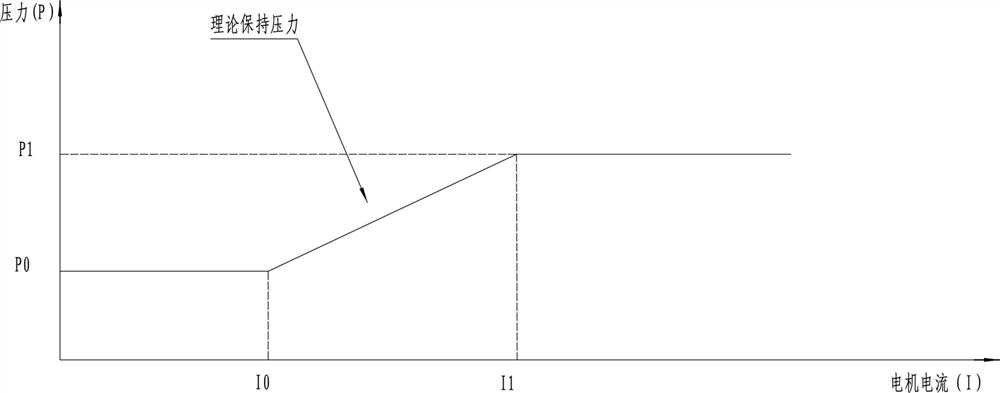

[0025] A method for calculating the holding pressure of the telescopic oil cylinder of the chain automatic tensioning system of the conveyor. It is an improvement based on the existing conveyor whose tail can adjust the telescopic length. A current detection unit is installed on the tail motor of the conveyor. A pressure detection unit is installed in the telescopic oil cylinder of the tail. The tail motor is the only source of driving force for the chain operation. The telescopic oil cylinder of the tail is connected to the hydraulic system to provide telescopic adjustment of the tail part. The current detection unit and the pressure detection unit , tail motor, telescopic oil cylinder and hydraulic system are all connected to the main controller, and the pressure maintenance of the telescopic oil cylinder is controlled by the following m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com