Quantitative intelligent container loading system for cement packaging

A technology for containers and packaging, which is applied in the field of intelligent container quantitative loading system for cement packaging, which can solve the problems of large manpower consumption, inability to measure, and slow packing speed, so as to improve work efficiency, facilitate unified weight calculation, and save labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

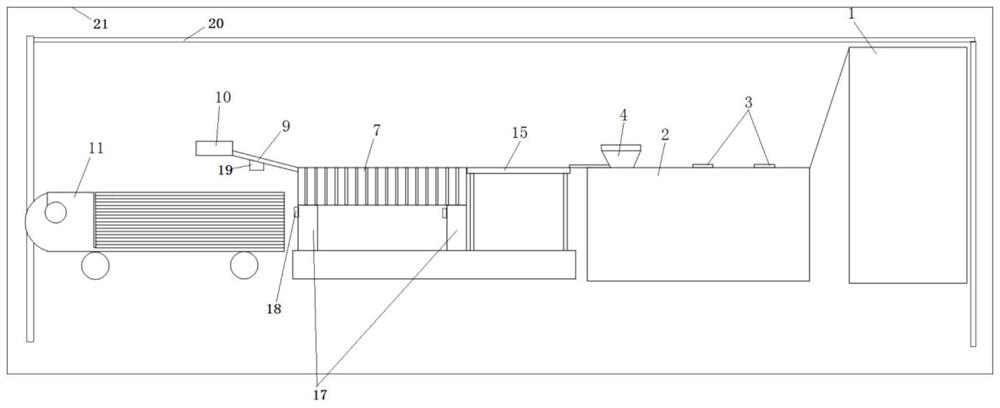

[0022] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention is a quantitative and intelligent container loading system for cement packaging, which includes a cement silo 1 connected with a belt scale 2, the belt scale 2 is a frequency conversion speed regulation type, and the belt scale 2 is provided with a number of stoppers Plate 3, scale hopper 4 is installed on belt scale 2, scale hopper 4 is connected with feed plate 5 and discharge plate 6, feed plate 5 is connected with belt conveying device 15, and belt conveying device 15 is installed at one end away from feed plate 5 There is a material buffer partition 16, and the material buffer partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com