Lifting platform

A lifting platform and lifting column technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of difficult assembly and difficult assembly of a single motor lifting platform, and achieve the effect of simplifying assembly steps and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

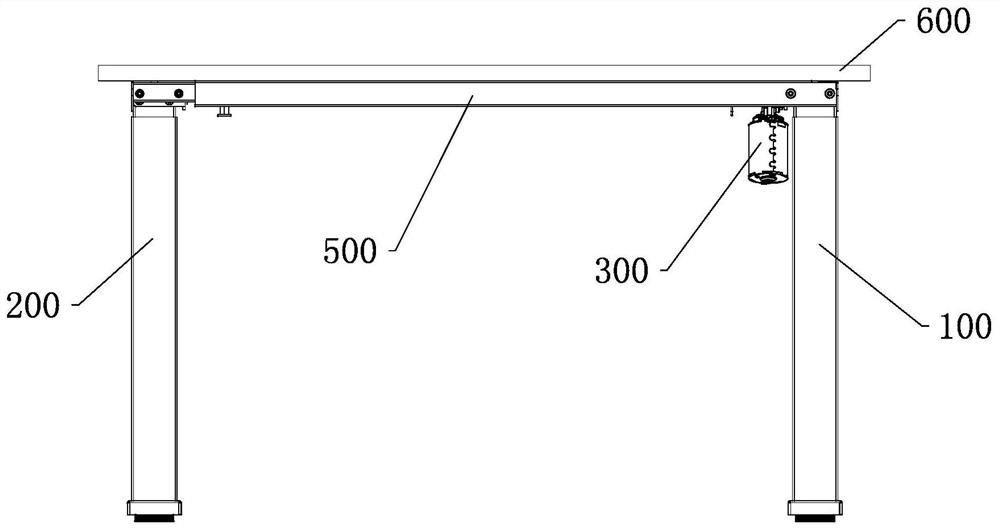

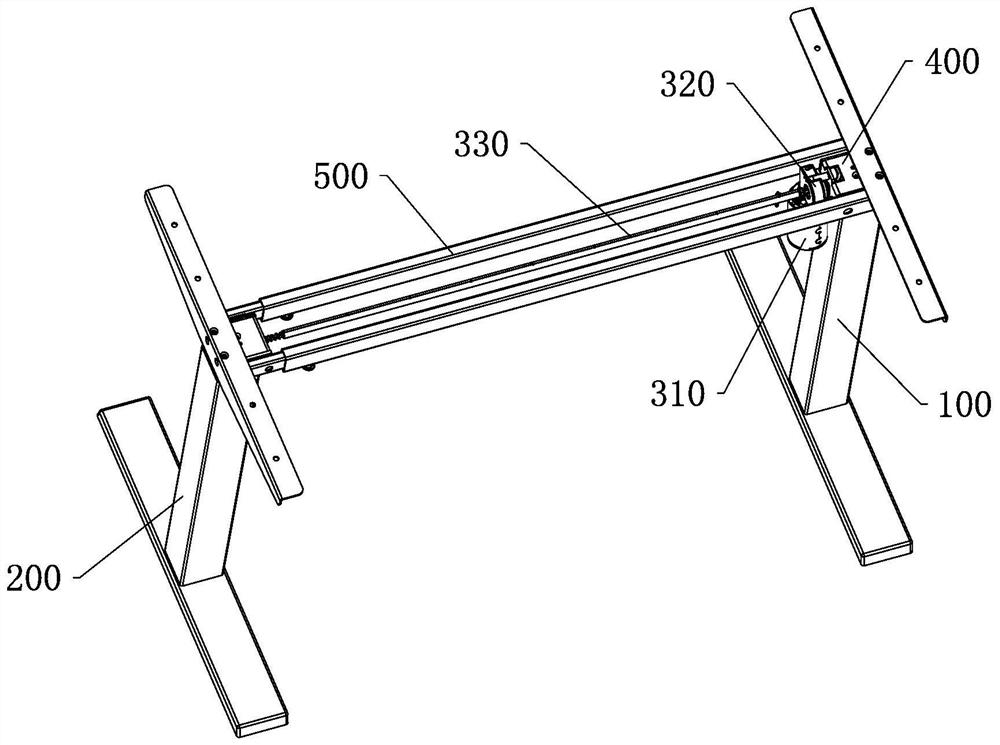

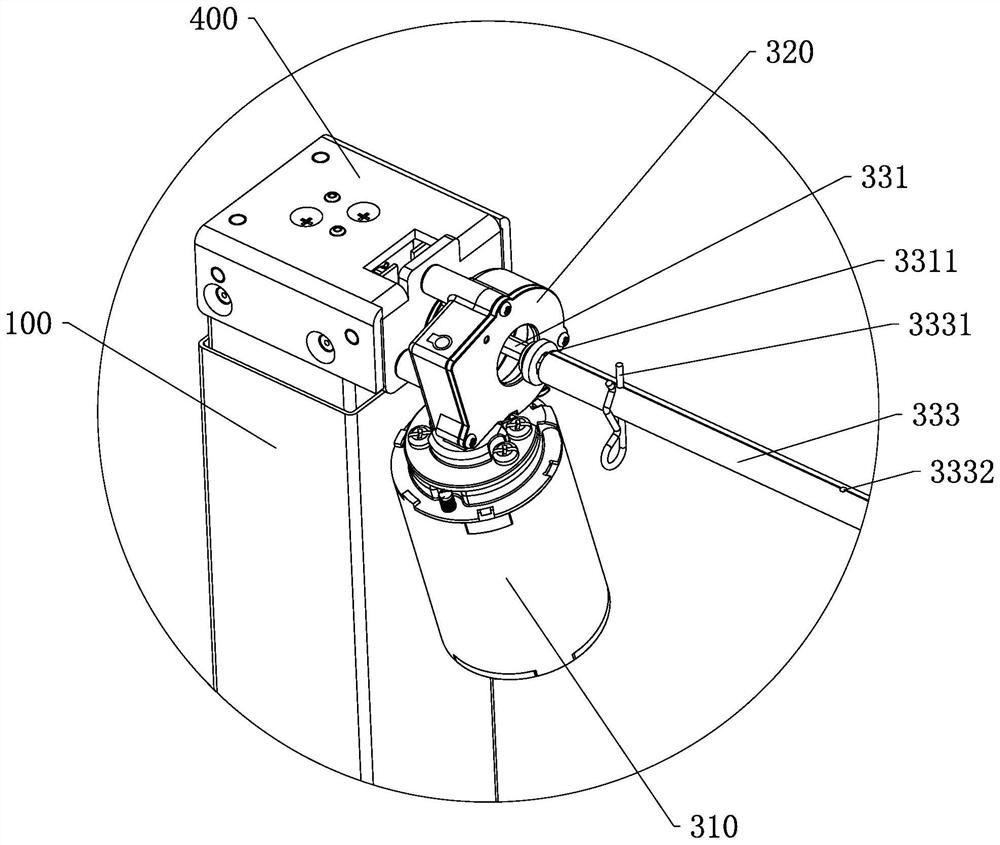

[0036] A lifting platform, such as Figure 1 to Figure 5 As shown, it includes a table top 600, a lifting column located at the bottom of the table top 600, a lifting assembly located inside the lifting column, and a driving assembly 300 located outside the lifting column and connected to the lifting column. The driving assembly 300 drives the lifting assembly through the lifting assembly. The column is lifted and lowered, and the top of the lifting column is provided with a pre-assembled part 400, and the driving mechanism and the lifting assembly are fixed on the pre-installed part 400 and matched in position through the pre-installed part 400. In the present invention, by installing the driving mechanism and the lifting assembly on the corresponding installation positions of the pre-installed part 400, the matching of the driving mechanism and the lifting assembly can be quickly realized, so that the installed driving mechanism can drive the lifting assembly to work , to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com