Passive anti-crack reinforced prefabricated bridge deck slab connecting structure and design method thereof

A technology for connecting structures and design methods, applied in bridge construction, design optimization/simulation, bridges, etc., can solve problems such as insufficient crack resistance, achieve flexible use, improve crack resistance, and improve crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

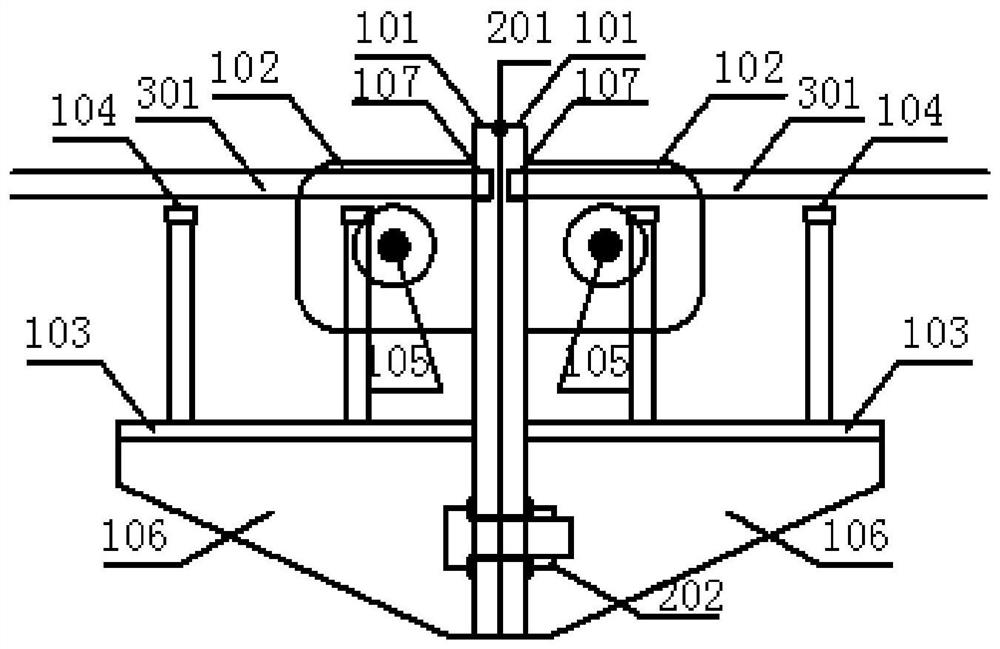

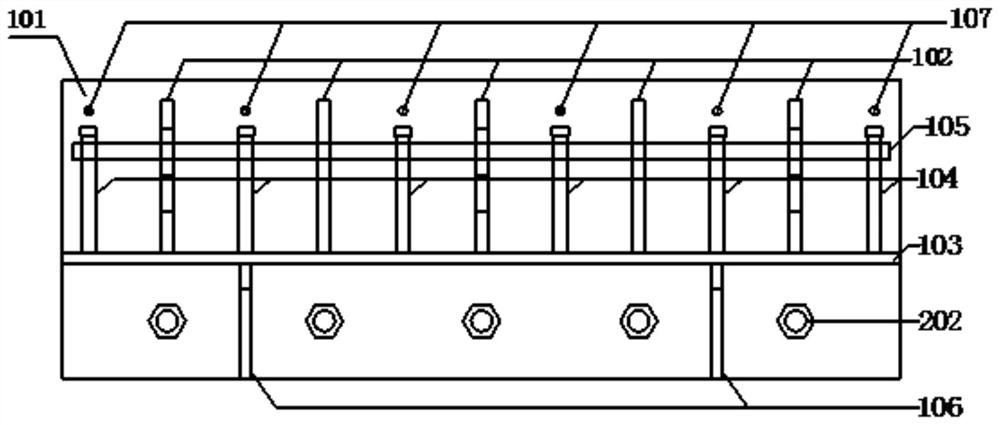

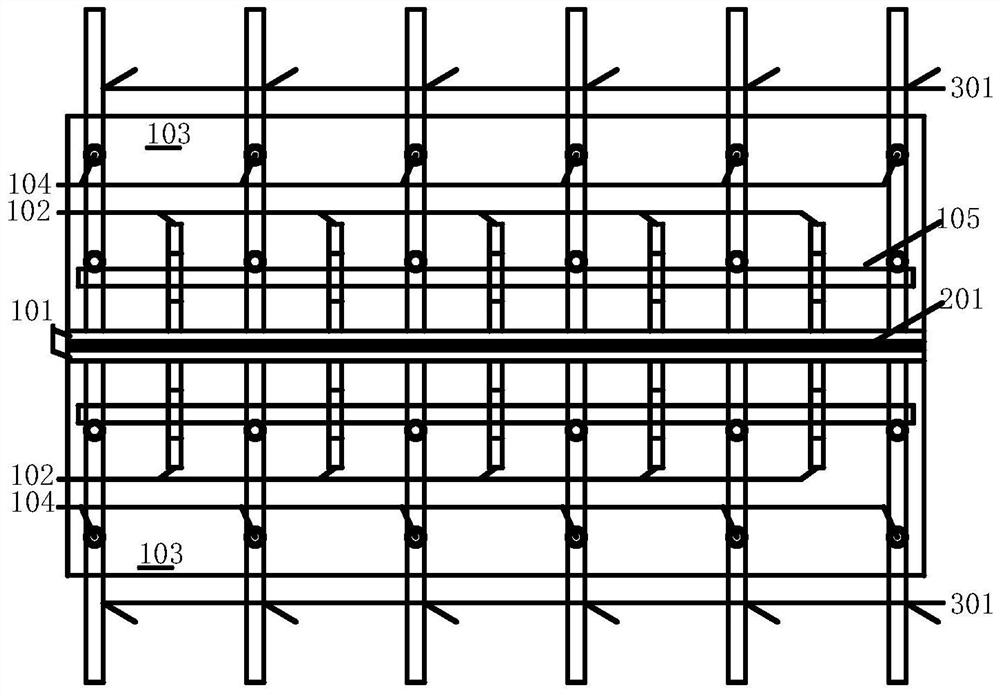

[0070] Such as figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a passive anti-cracking enhanced prefabricated bridge deck connection structure, including end connectors arranged at the ends of the concrete slab, and the end connectors include vertical plates 101 located on the side of the concrete bridge deck and the transverse plate 103 on the underside of the concrete bridge deck;

[0071] A plurality of perforated stiffening plates 102 are vertically arranged on the side of the vertical plate 101, steel bars 105 are pierced in the holes of the perforated stiffening plates 102, and both the perforated stiffening plates 102 and the steel bars 105 are buried in the concrete bridge deck; the top of the vertical plate 101 A plurality of reinforcement connection holes 107 are provided, and the main reinforcement bars 301 of the bridge deck are inserted into the reinforcement connection holes 107, and the main reinforcement bars 301 o...

Embodiment 2

[0082] Based on the connection structure described in the above-mentioned embodiment 1, the embodiment of the present invention also provides a design method of a passive anti-cracking enhanced prefabricated bridge deck connection structure, including the following steps:

[0083] S1. Set the size of the above-mentioned connection structure, the allowable crack width at the interface between the vertical slab and the side of the concrete bridge deck, and the spacing between the stiffened slabs with holes;

[0084] In this embodiment, the present invention determines the length, width, and thickness of the vertical slab, stiffened slab with holes, transverse slab, and stiffener according to the structural requirements, wherein the width of the vertical slab and the width of the transverse slab are the same width as the width B of the bridge deck; Determine the allowable crack width at the interface between the vertical slab and the side of the concrete bridge deck according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com