Rolling type waterproof junction box

A waterproof and junction box technology, which is applied in the field of junction boxes, can solve problems such as waterproof leaks, potential safety hazards, and impact on the service life of junction boxes, and achieve the effects of reducing potential safety hazards, prolonging service life, and making up for waterproof leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

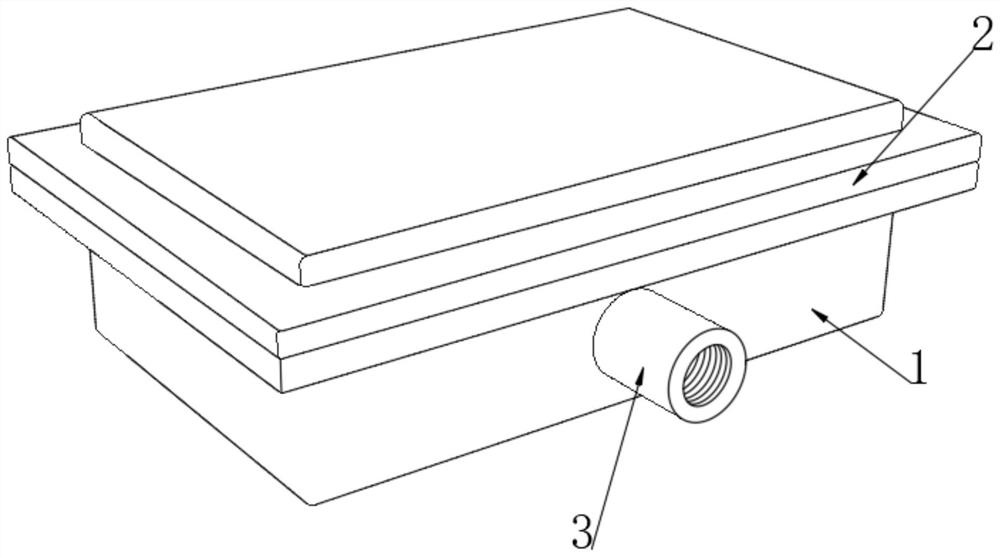

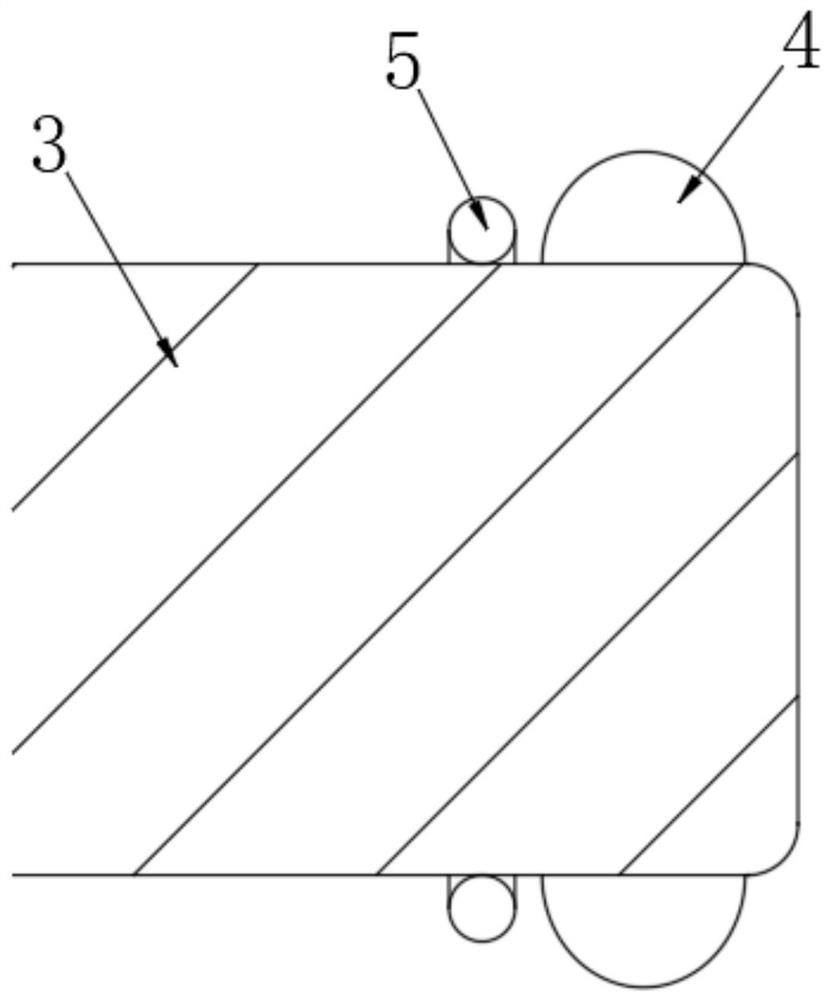

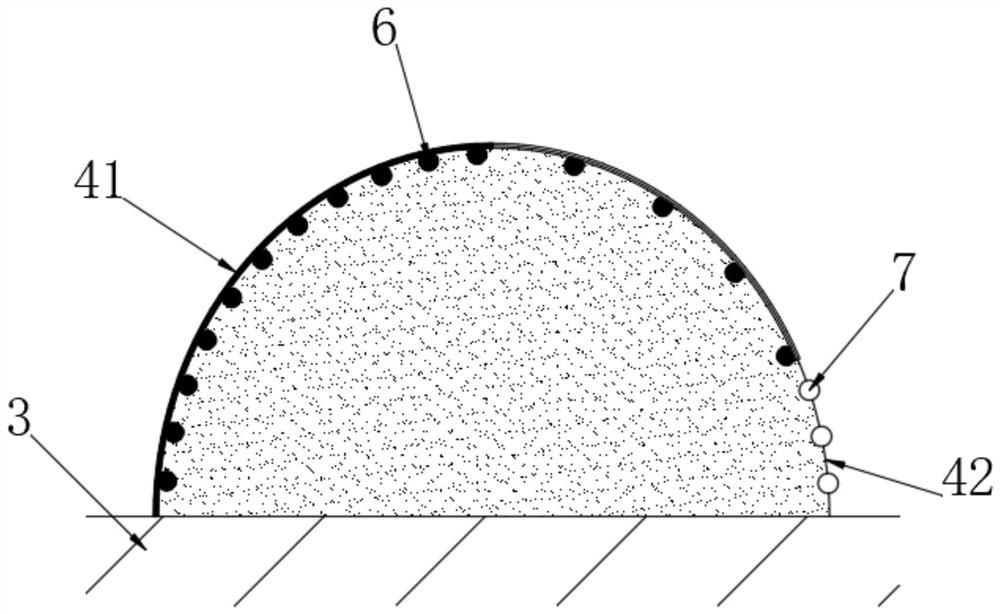

[0041] see Figure 1-3 , a rolling type waterproof junction box, including a box body 1, the upper end cover of the box body 1 is provided with a box cover 2, and the outer end of the box body 1 is provided with a wiring tube 3, and the wiring tube 3 is far away from the outer end of the box body 1 The fixed part is connected with a horizontal convex bag 4, and the outer end of the cable pipe 3 is also provided with a pressure ring 5, which is located between the horizontal convex bag 4 and the box body 1, and the interior of the horizontal convex bag 4 is filled with compressed air. Air, compressed air makes the expansion outer bag 42 have a certain hardness after expansion, and at the same time enables the expansion outer bag 42 to be squeezed and contacted with the electric wire after expansion, which is convenient for the overflow of the glass glue in the waterproof rubber ring 7, and the horizontal outer convex bag 4 The compression ratio of the air is not more than 2 tim...

Embodiment 2

[0046] The biggest difference between this embodiment and embodiment 1 is that waterproof rubber ring 7 and limit stay cord 8 are not provided, and other structures are consistent with embodiment 1. After the wires are expanded and wrapped, glass glue can be manually squeezed between the lateral convex bag 4 and the wires, thereby assisting it to form a glass glue layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com