Sealing fireproof door for ship

A technology for fire doors and ships, applied in the field of fire doors, can solve problems such as complex sealing structure and difficult process, and achieve the effects of low thermal conductivity, improved aesthetics, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

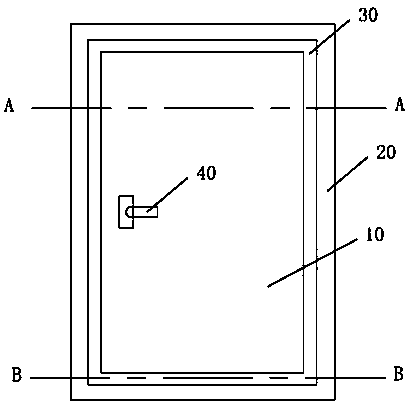

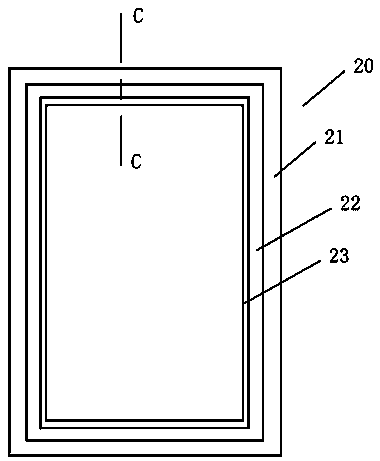

[0025] Example: such as Figure 1-5 As shown, a sealed fire door for ships includes a door panel 10, a fireproof door frame 20 and a fireproof handle 40. The door panel 10 is connected to the fireproof door frame 20 through a fireproof hinge, and the fireproof handle 40 is arranged on the door panel 10. The fireproof The outer edge of the door frame 20 is provided with a first step 21, a second step 22 and a baffle 23 in sequence, the second step 22 protrudes from the first step 21, the baffle protrudes from the second step 22, The outer edge of the second step 22 is provided with a ring of fireproof sealing strip 24, and the fireproof sealing strip is used to seal the gap between the door panel 10 and the fireproof door frame 20;

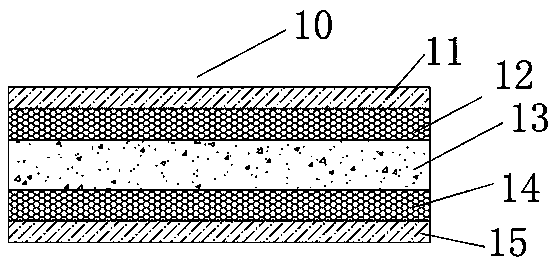

[0026] The door panel 10 includes an outer panel 11, a first sound insulation panel 12, a door core panel 13, a second sound insulation panel 14 and an inner panel 15 connected in sequence. When the door panel 10 is closed, the outer panel 11 is cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com