Automatic rubber cap pressing machine

A glue-pressing and automatic technology, applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve problems such as difficulty in meeting large-scale production and processing, damage to lead rods, poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

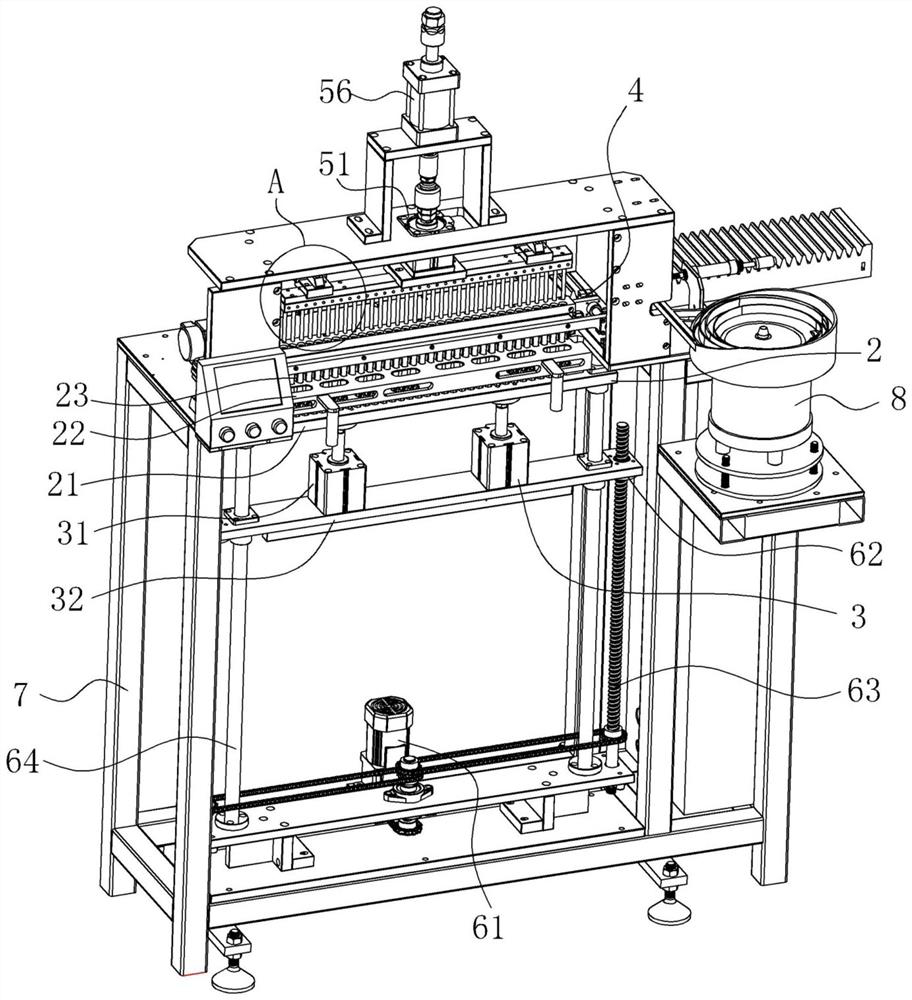

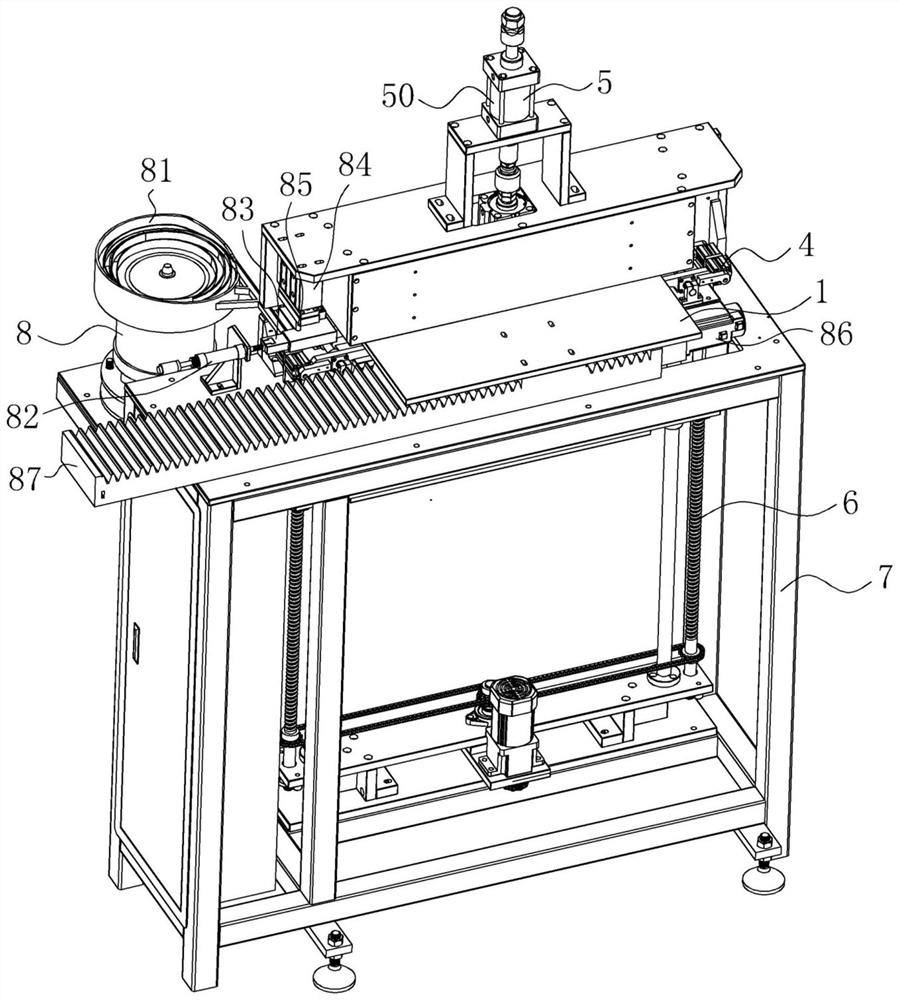

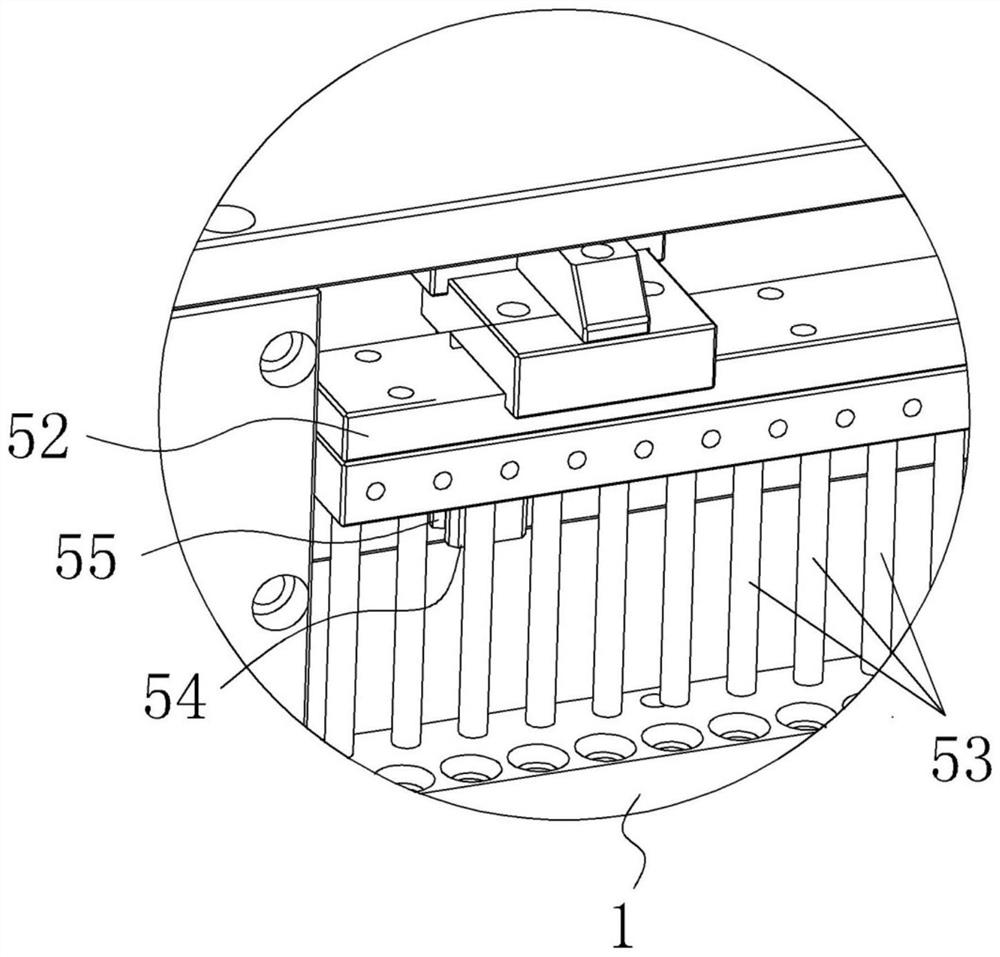

[0029] refer to Figure 1 to Figure 11 , an automatic rubber cap pressing machine of the present invention, comprising a rubber cap seat 1, an electric heating tube seat 2, a lifting mechanism 3, a clamping mechanism 4, a rubber cap pressing mechanism 5, a height adjustment mechanism 6, a frame 7 and a rubber cap Conveying mechanism 8.

[0030] The rubber cap seat 1 is provided with a plurality of rubber cap placement grooves 11, and the rubber cap accommodation grooves 11 can be used for placing the rubber caps.

[0031] The rubber cap conveying mechanism 8 includes a vibrating plate 81, a pushing cylinder 82, a push block 83, a pressing cylinder 84, a thimble 85, a stepping motor 86 and a slide rail 87. The rubber cap seat 1 is fixedly installed on the slide rail 87 by bolts, and the slide rail 87 is connected with the stepper motor 86, so that the steppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com