3D printed structure

A 3D printing and structural layer technology, applied in the field of 3D printing structures, can solve problems such as inflexibility, reduced flexibility, and increased material weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

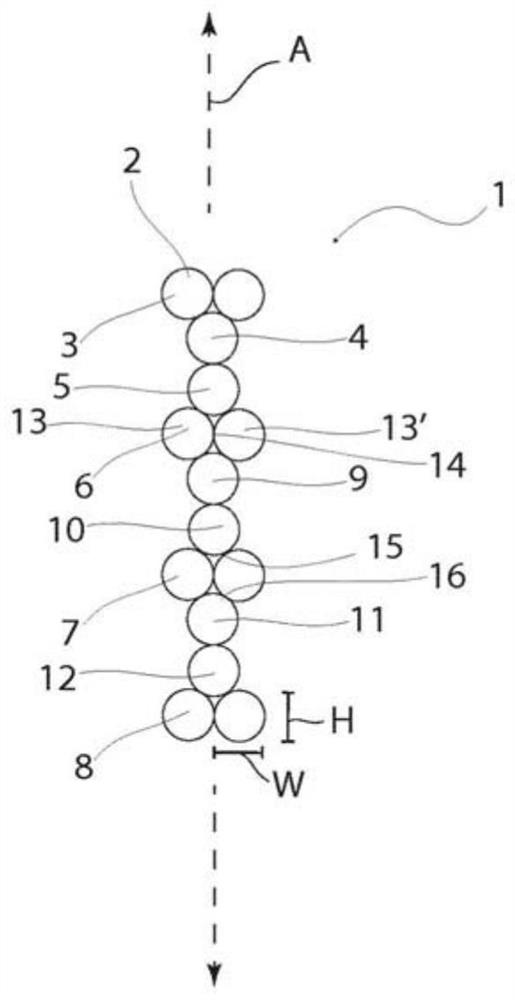

[0098] Fig. 1 shows a first exemplary embodiment of a 3D printed structure 1 with a first wall 2 having a plurality of layers extending along a first axis A, seen in a schematic cross-sectional view. The first wall 2 comprises a first secondary structural layer 3 , a first flexible layer 4 and a second flexible layer 5 . In this exemplary embodiment, the first wall 2 includes a second level structure layer 6, a third level structure layer 7 and a fourth level structure layer 8, wherein the second level structure layer 6 and the tertiary structure layer 7, and each of the tertiary structural layer 7 and the fourth secondary structural layer 8 is separated by two flexible layers 9, 10, 11, 12 respectively. That is, the structure in which the first secondary structural layer 3 and the first 3 and second pliable layers 4 is repeated in the longitudinal direction A of the wall 2 along the length of the wall 2 .

[0099] The primary structure wall 3 and the first flexible wall 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com