Stereolithography apparatus having a detection unit for optical adjustment and image modification

A technology of stereolithography and detection unit, which is applied in the field of calibration technology of stereolithography equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

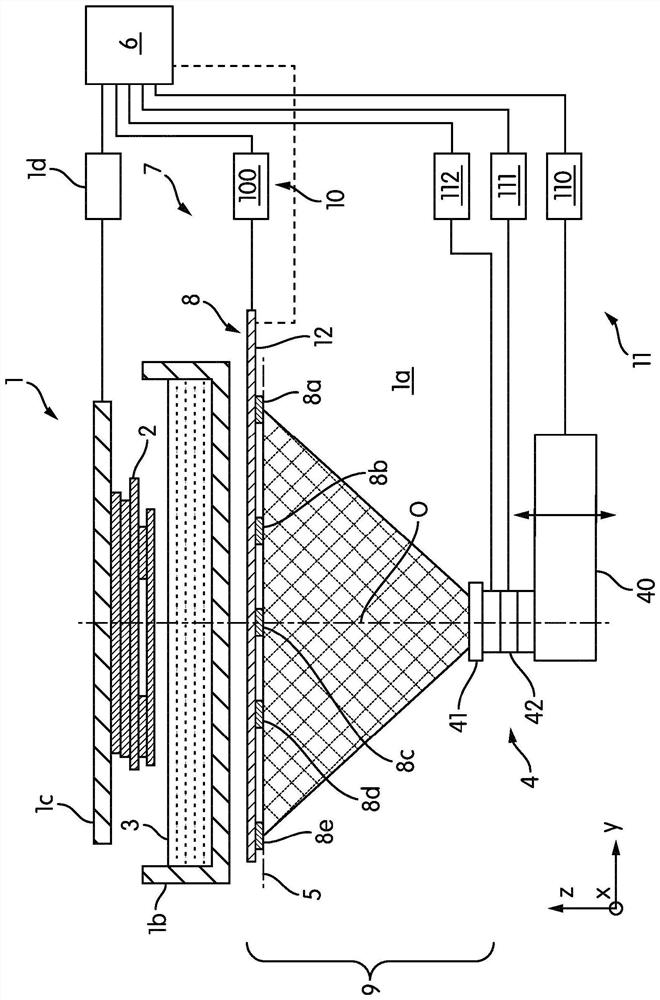

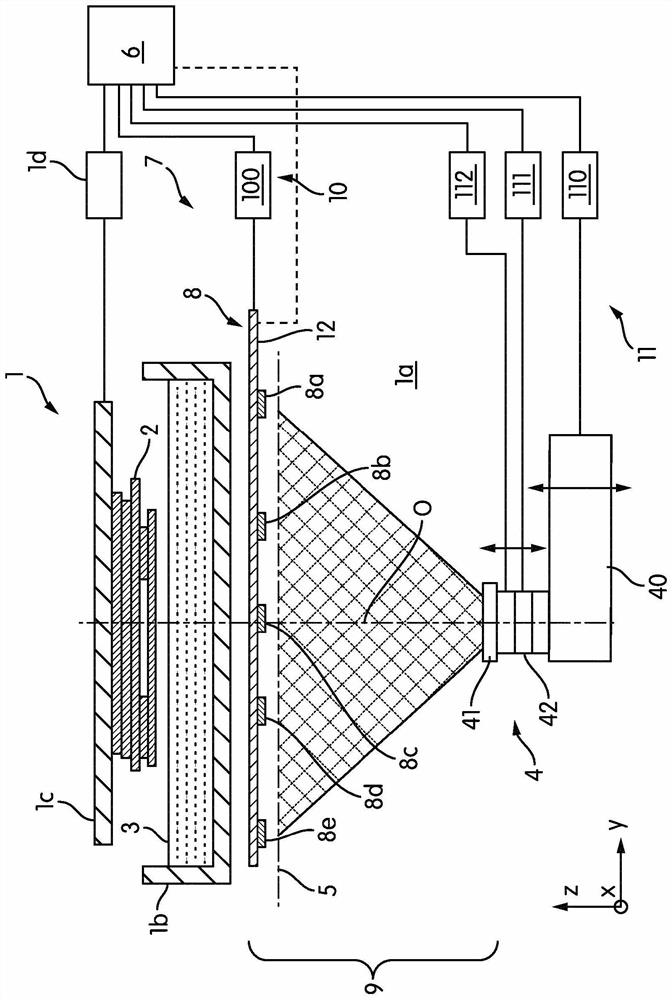

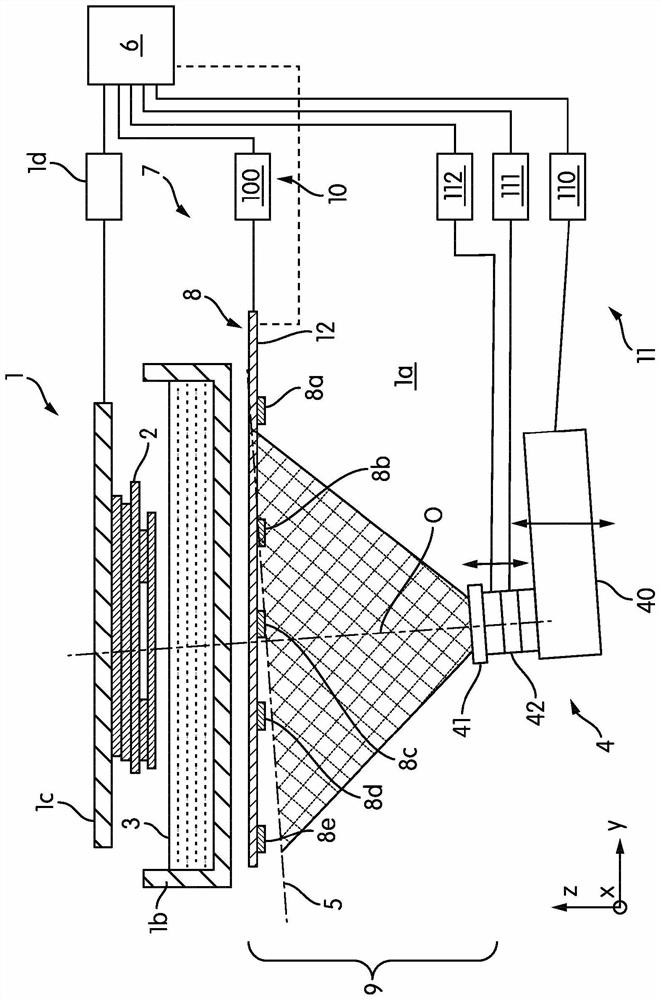

[0085] Figure 4 A stereolithography apparatus ( 1 ) according to a first embodiment is shown during the generation process of a three-dimensional object. Such as Figure 4A stereolithography apparatus (1) is shown having a machine chamber (1a) for stepwise and / or continuous generation of at least one three-dimensional object (2). A three-dimensional object (2) is generated from a photocurable substance (3) stored inside the barrel (1b). The photocurable substance (3) is in fluid form and can have various consistencies, for example also in the form of a paste. , the photocurable substance (3) is attached to the platform (1c) after it has cured. The platform (1c) can be driven up or down relative to the tub (1b) by at least one motor and actuator (1d). All processes in the stereolithography apparatus (1) are controlled and adjusted by the control unit (6). The stereolithography apparatus (1) also has an interface for wireless and / or wired communication with the CAD CAM mod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap