Extrusion process for multi-color silica gel coated flexible LED lamp strip and discharging device adopting process

An LED light strip and extrusion process technology, applied in the field of lamps, can solve the problems of wasting resources, the light strip cannot be tensioned, affecting the extrusion process of the light strip, etc., and achieves the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

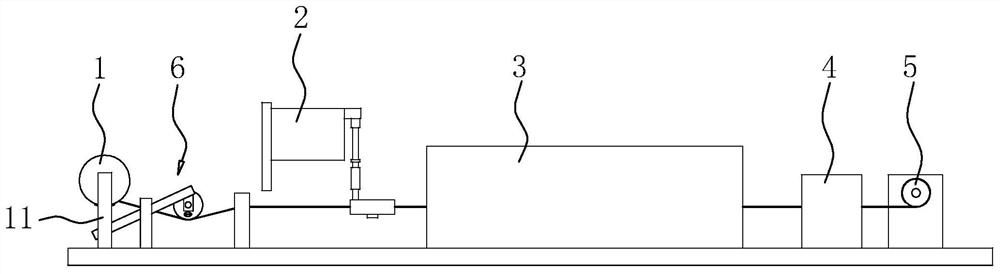

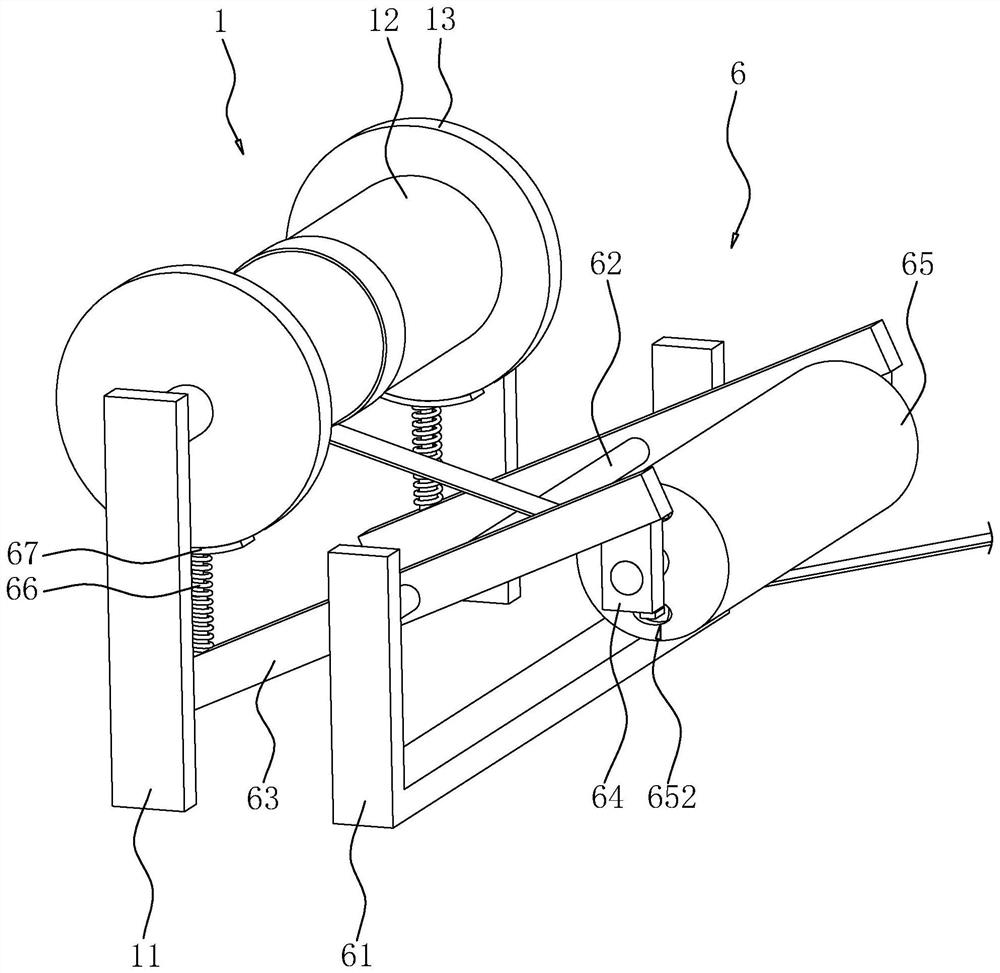

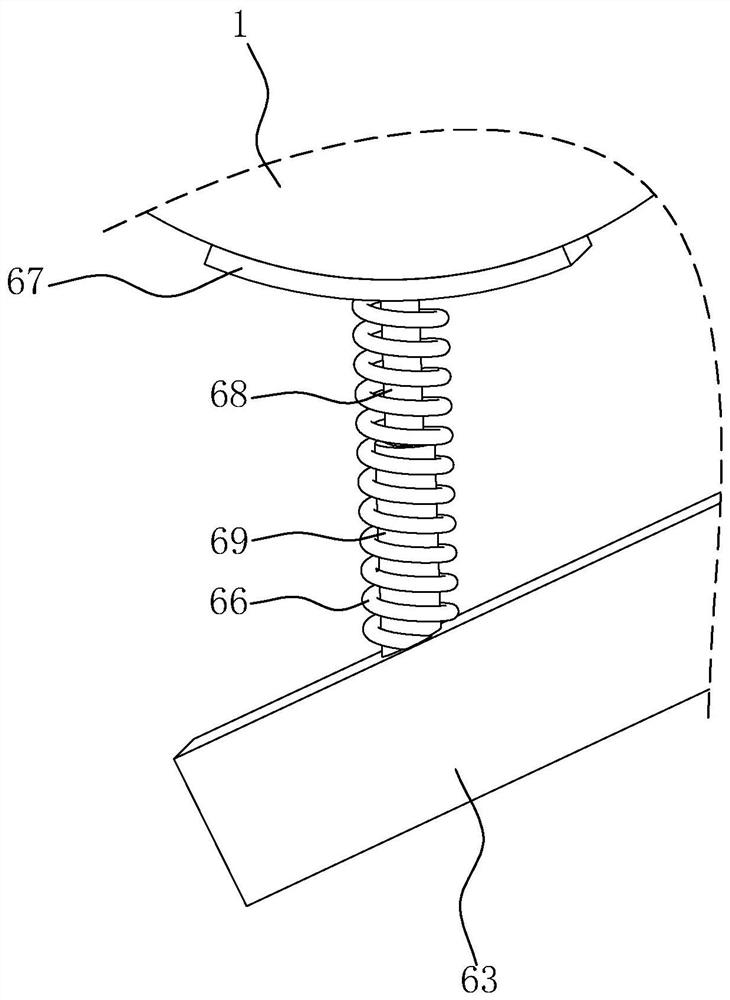

[0037] Contraction below Figure 1-4 Further detailed description of the present application.

[0038] The present application examples disclose a discharge device for multi-color silica gel coating flexible LED lamp strip extrusion process. Refer figure 1 and figure 2 On one side of the discharge device sequentially provided a silica gel extruder 2, a hot air vulcanized tunnel furnace 3, a traction device 4, and a collecting device 5, and a disc supply frame comprising two support frames supported on the ground 11, two support frames. 11 is rotated between the discharge shafts 1, the discharge shaft 1 is used to wound the lamp tape to be processed.

[0039] A tensioning mechanism 6 having a tension of the lamp belt and the silica gel extruded device 2, and the lamp strip is swimmed after the discharge shaft 1 is discharged through the tensioning mechanism 6, silicone extruder 2, heat The air vulcanized tunnel furnace 3, the traction device 4 and the collecting device 5, wherein th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com