Truss type replaceable energy dissipation coupling beam with buckling restrained braces

A technology of buckling restraint and connecting beams, which is applied in the direction of truss beams, truss structures, joists, etc., can solve the problems of insufficient energy dissipation capacity, no replacement of energy dissipation dampers, and difficult repairs, etc., to achieve convenient processing and improve earthquake resistance Properties, the effect of convenient maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

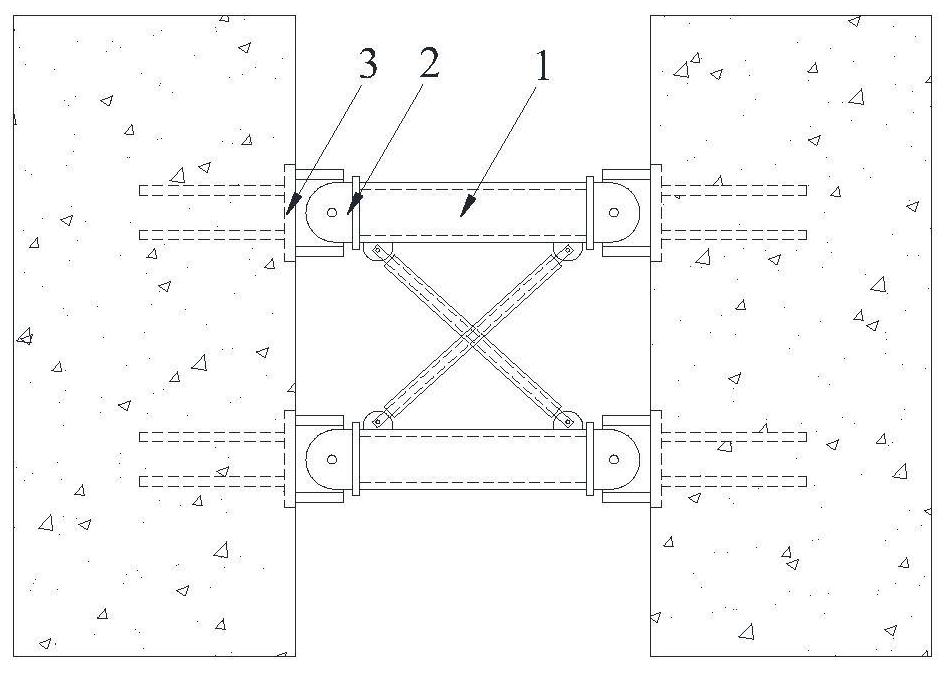

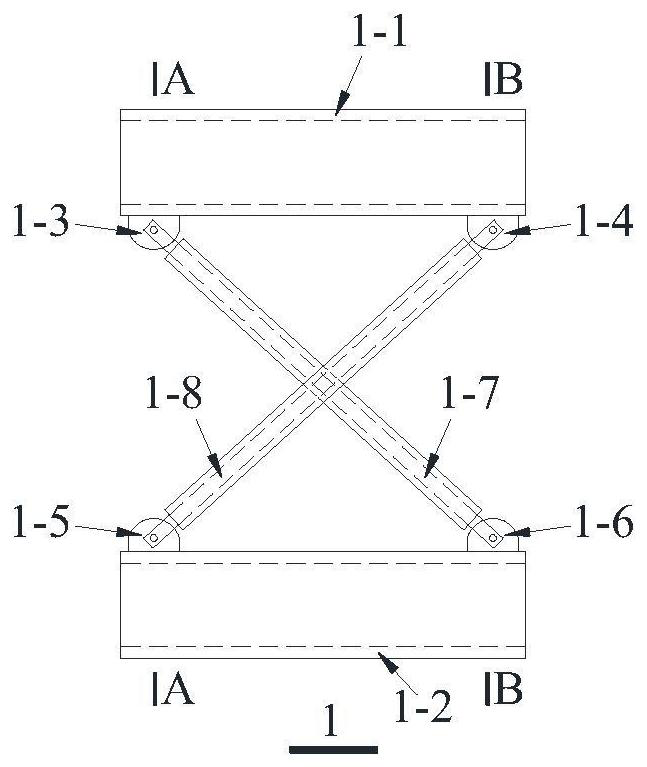

[0054] Such as Figure 1-13 Shown: A truss-type replaceable energy-dissipating connecting beam with buckling restraint bracing, including truss-type connecting beam 1, connecting beam end member 2 and embedded connecting steel plate 3:

[0055] The truss-type connecting beam 1 includes a square steel pipe upper chord 1-1, a square steel pipe lower chord 1-2, a hinged connector A1-3, a hinged connector B1-4, a hinged connector C1-5, and a hinged connector D1- 6. Buckling restraint support A1-7, buckling restraint support B1-8; square steel pipe upper chord 1-1 and square steel pipe lower chord 1-2 are respectively used as the upper chord and lower chord of truss-type connecting beam 1, and hinged connection A1- 3. The hinged connectors B1-4 are respectively fixed on the two ends of the lower surface of the upper chord 1-1 of the square steel pipe, and the hinged connector 1-5C and the hinged connector D1-6 are respectively fixed on the lower chord 1-2 of the square steel pipe. ...

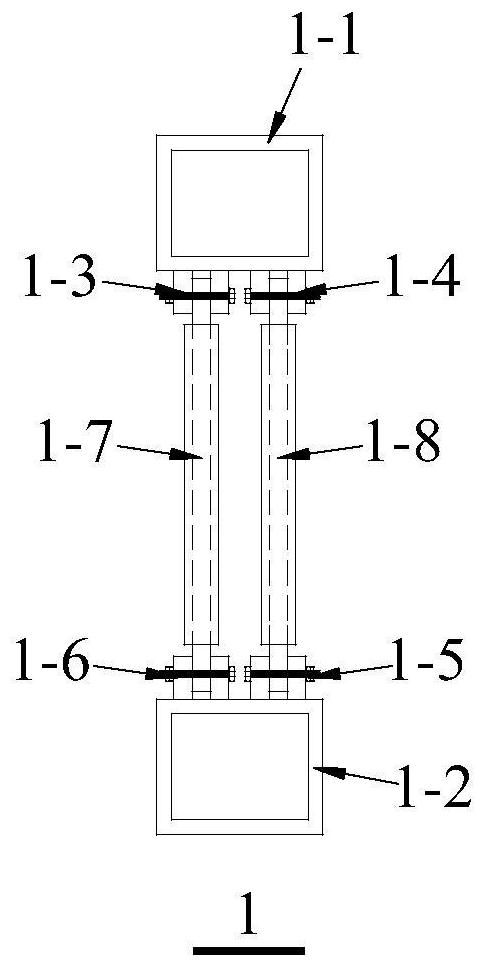

Embodiment 2

[0065] Such as Figures 14 to 16Shown: this embodiment is the same as the rest of embodiment 1, the difference is that the square steel pipe upper chord 1-1 and the square steel pipe lower chord 1-2 in the truss type connecting beam 1 are not hollow square steel pipes, but Concrete steel tubes are used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com