Flow control valve with three-way ball

A technology for flow control valves and through balls, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as troublesome and insufficient precision, and achieve the effect of saving raw materials and better flow limiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

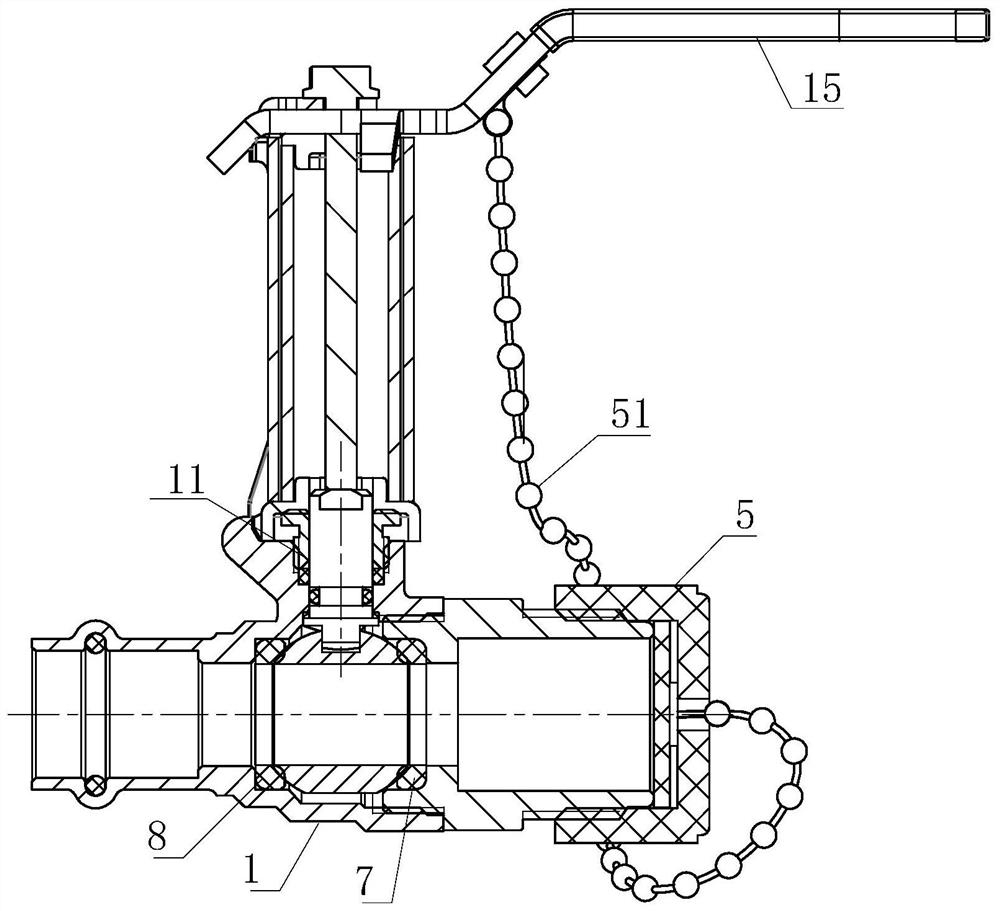

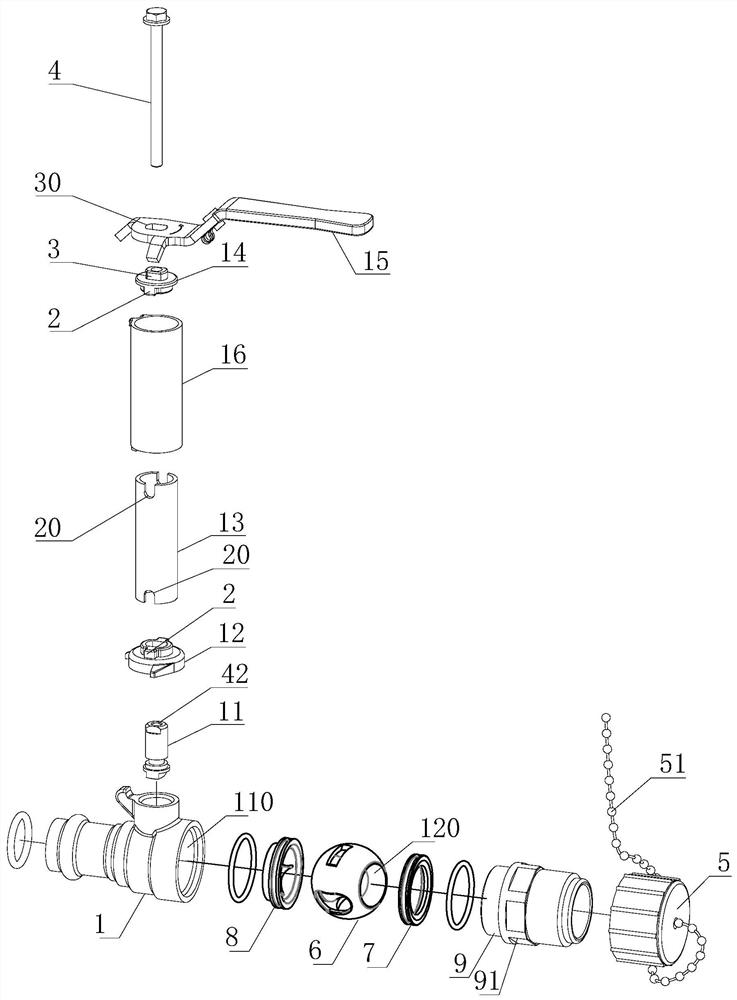

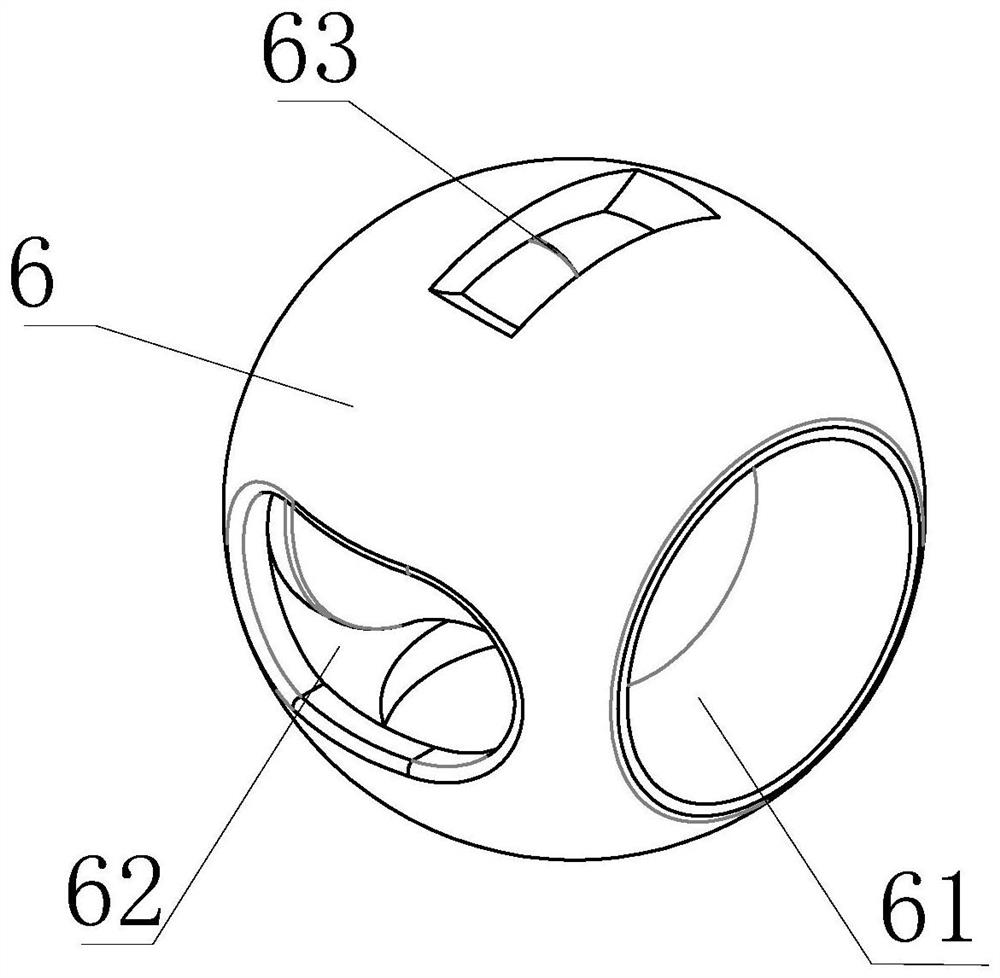

[0035] see Figure 1 to Figure 7 , this embodiment provides a flow control valve with a three-way ball, including a valve body 1, the top of the valve body 1 is rotatably connected to a handle 15 through a valve stem 11, a valve ball 6 is arranged inside the valve body 1, and the The main channel 110 is opened through the valve body 1, the valve ball 6 is rotatably connected in the main channel 110, and the secondary channel 120 is opened through the valve ball 6, when the valve ball 6 is rotated and opened, the main channel 110 and the The secondary channels 120 are connected.

[0036] Both sides of the valve ball 6 are respectively provided with a valve seat 7 and a flow limiting sheet 8, and the valve seat 7 and the flow limiting sheet 8 are located between the outer wall of the valve ball 6 and the inner wall of the main channel 110; the valve seat 7 is Annular, and the area of the annular mouth is larger than the cross-sectional area of the auxiliary flow channel 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com