Double Wall Big Elbow

A double-wall and large-bend technology, which is applied in combustion methods, lighting and heating equipment, and continuous combustion chambers, can solve problems such as cracks in parts, affecting engine life and safety, and poor design of the two-layer wall connection structure to achieve cooling Excellent effect and good maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

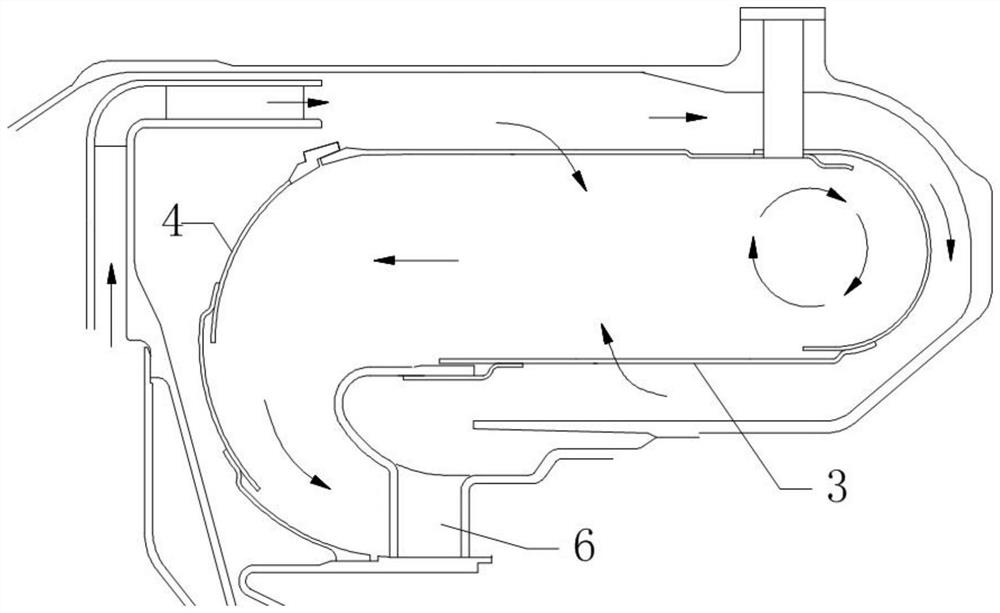

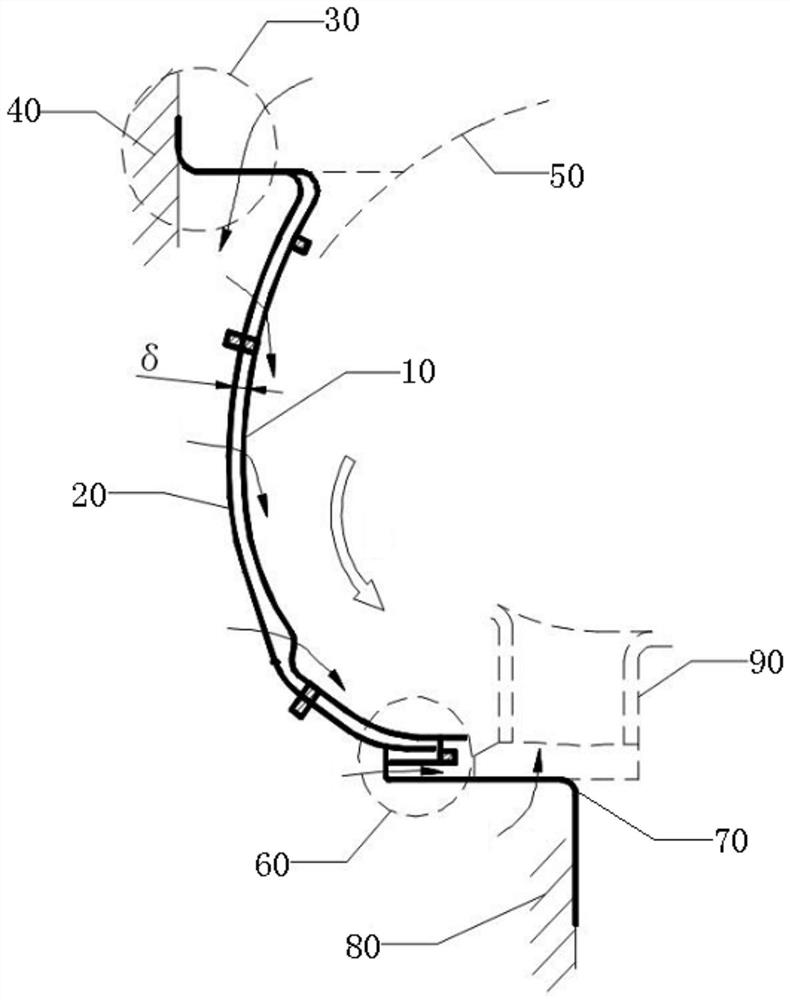

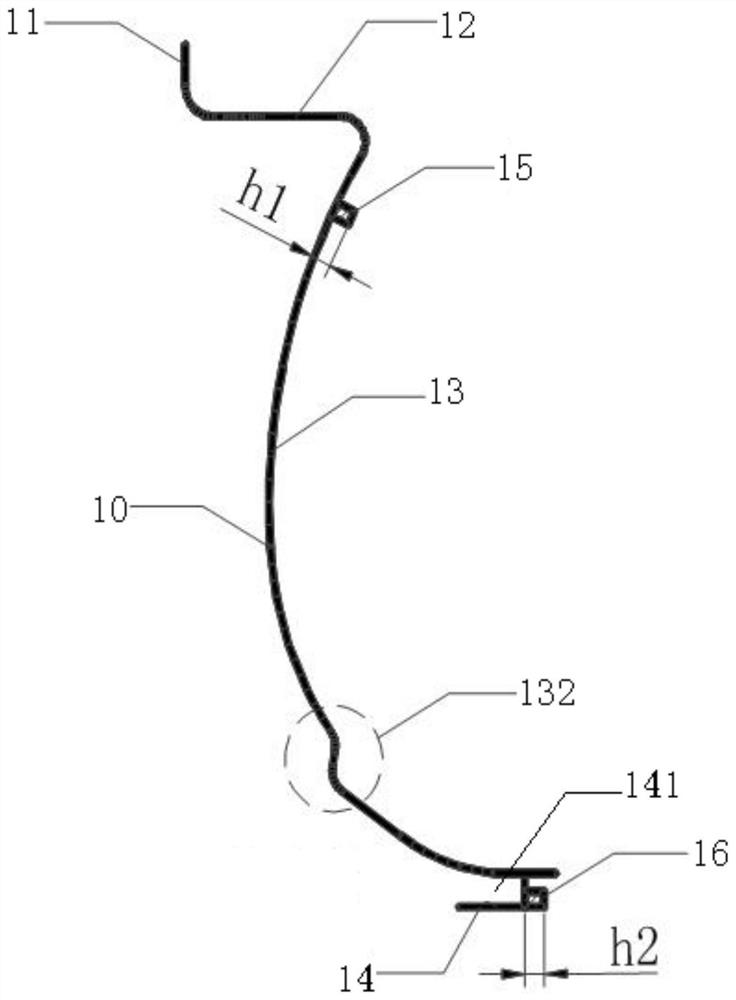

[0037] refer to figure 2 , the preferred embodiment of the present invention provides a double-walled large elbow, which is applied to the return combustion chamber of an aero-engine. The inlet ends of the inner wall assembly 10 and the outer wall assembly 20 are connected to form a supporting structure 30 for supporting against the diffuser 40 in the axial direction, and then passing through the diffuser 40 to the inlet end of the double-walled large elbow It is axially limited, and at the same time, the inlet end of the double-walled large elbow has free thermal expansion in the radial direction. The supporting structure 30 is also used to support the flame tube outlet 50, so that the flame tube outlet 50 is sealedly connected with the double-walled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com