Changeable embankment model manufacturing device

A technology for making devices and models, applied in teaching models, educational appliances, instruments, etc., can solve the problems of low use rate of mold templates, large labor and financial resources, and large demand for templates, and achieve high practicability, accuracy, Reduced production workload and high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

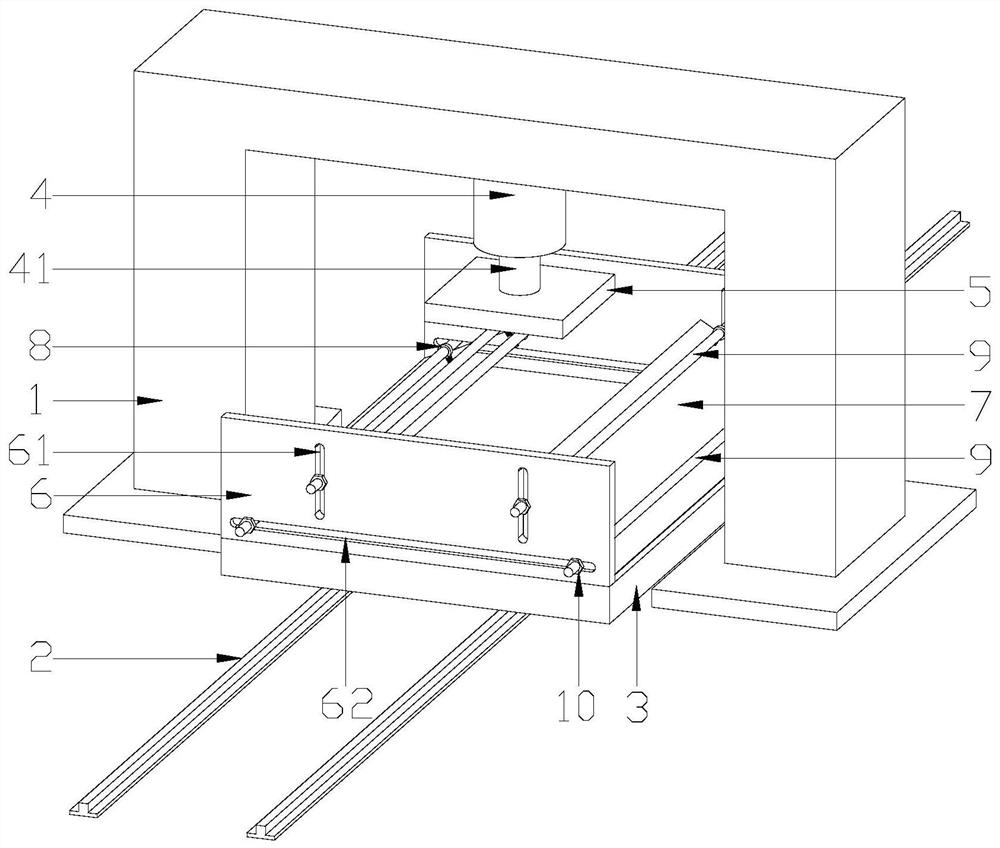

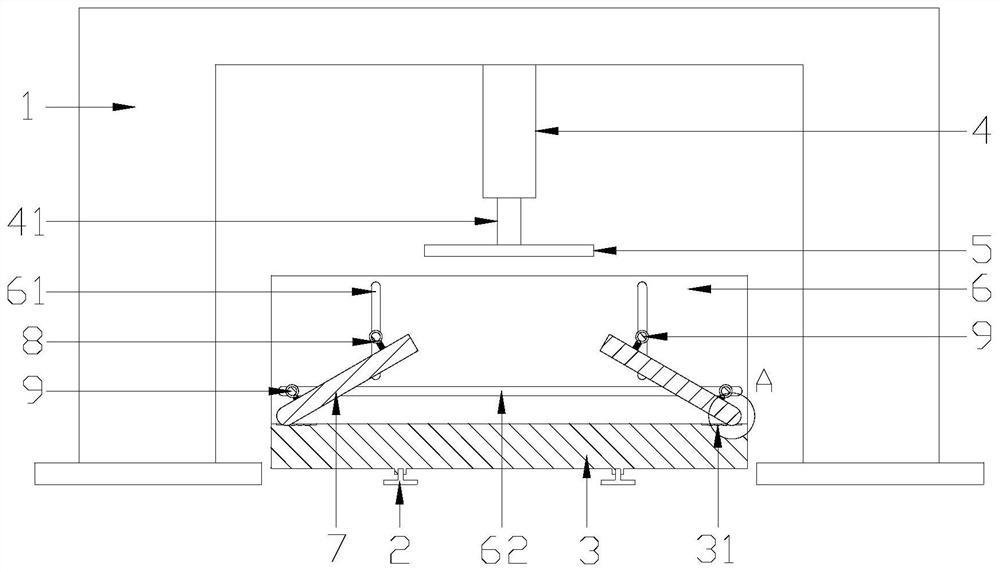

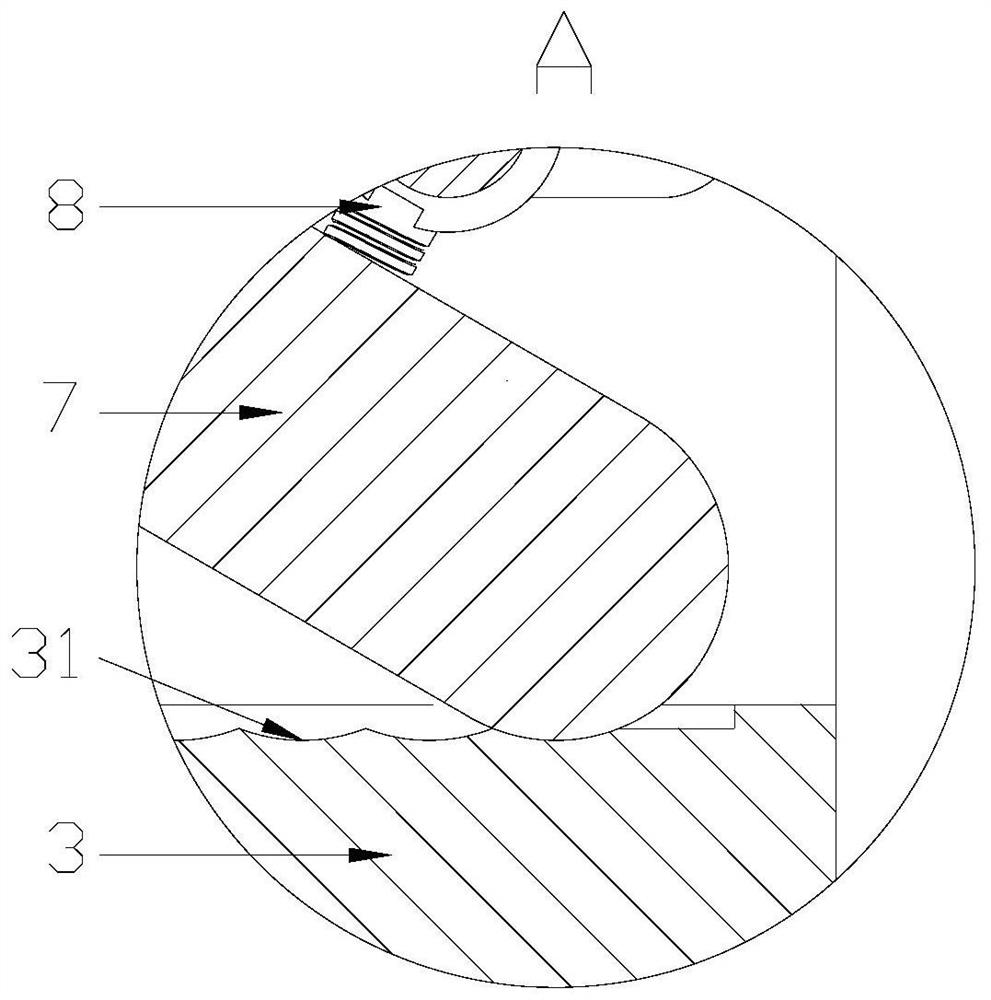

[0018] Embodiment 1: as Figure 1 to Figure 3 Shown, a kind of changeable embankment model making device, it comprises gantry 1, track 2, platform 3; Be provided with track 2 below gantry 1; On the beam of the gantry 1, a hydraulic cylinder 4 with a piston rod 41 protruding downwards is vertically provided; a pressure plate 5 is hinged at the top of the piston rod 41; The fixed formwork 6 of fixed formwork 6; On the platform 3 top surface between fixed formwork 6, split activity is provided with the movable formwork 7 that two board faces are relatively inclined to set, and the angle between movable formwork 7 and the platform according to the needs of making model is 10°~50°; grooves 31 arranged in parallel are provided on the surface of the platform 3; the length direction of the grooves 31 is perpendicular to the surface of the fixed formwork 6; the bottom of the movable formwork 7 is placed in the groove 31, Groove 31 guarantees that pressing plate 5 is when compacting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com