Turnover discharging device for lead-acid storage battery grid

A technology of lead-acid batteries and unloading devices, which is applied in the direction of electrode carriers/collectors, etc., can solve the problems affecting the grid processing process, laborious and laborious, etc., and achieve the effects of convenient grinding operations, reducing manual operations, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

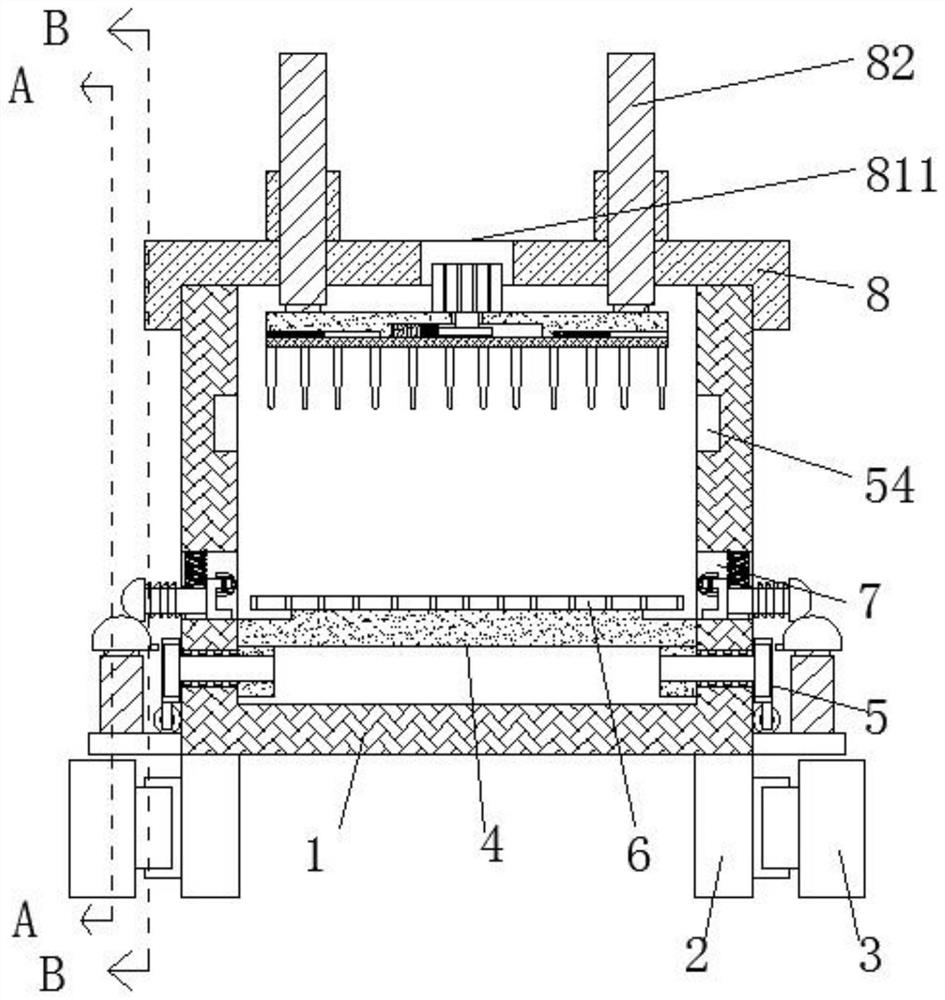

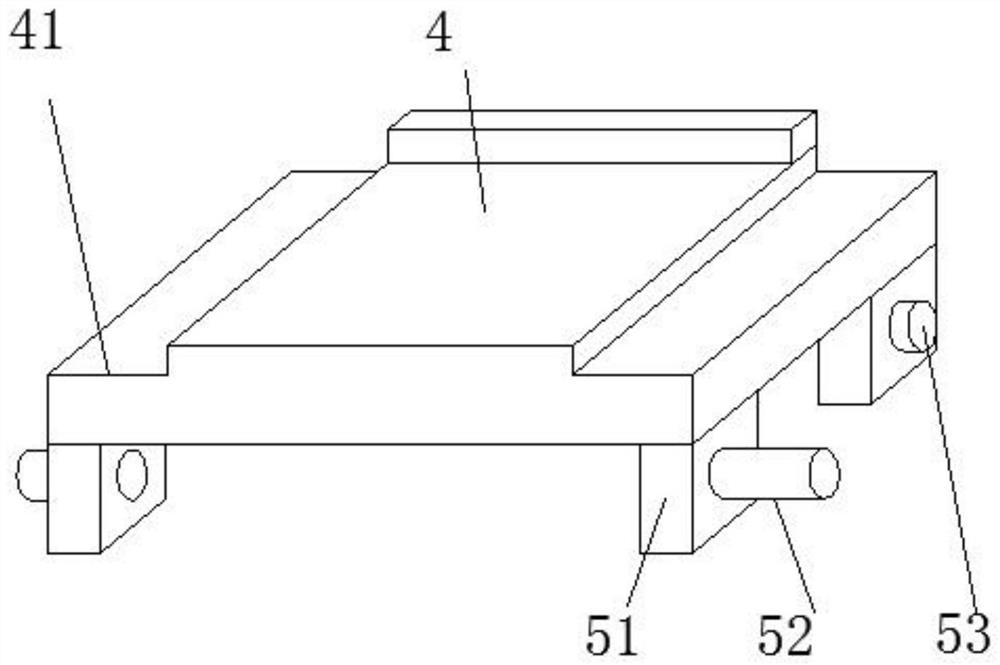

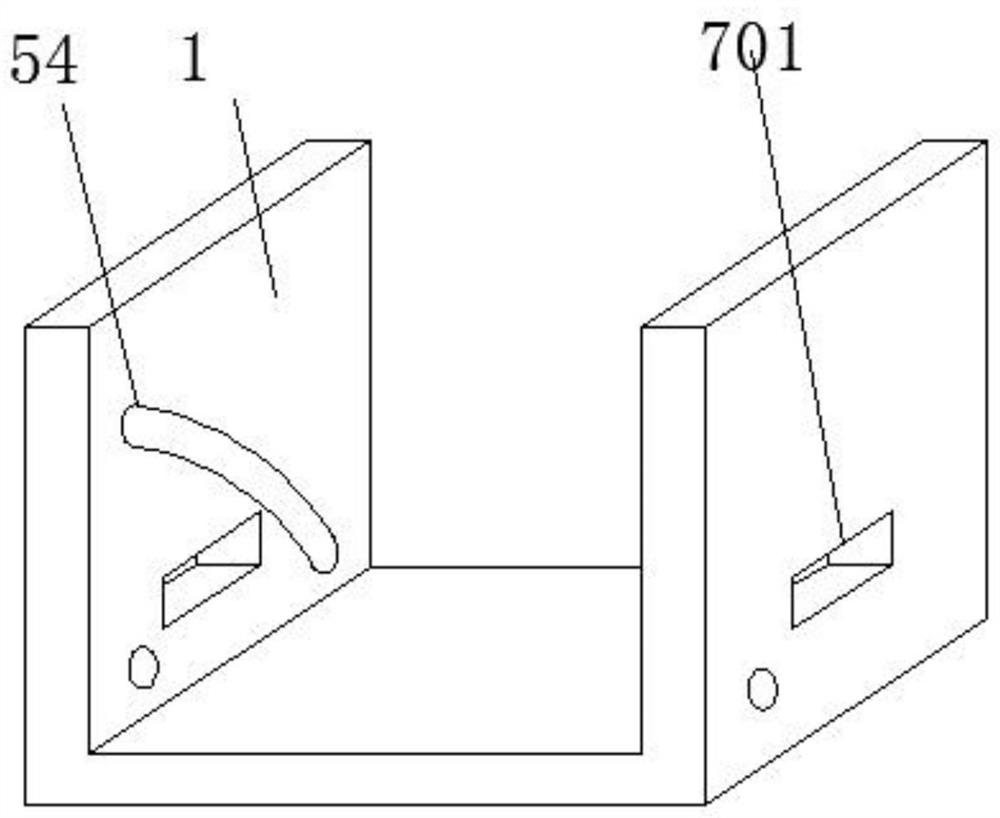

[0029] Such as figure 1 As shown, the flipping unloading device for the lead-acid battery grid includes a support frame 1, fixed plates 2 are fixedly connected to both sides of the bottom of the support frame 1, and a linear slide module is fixedly connected to the outer side of the fixed plate 2 3. The inside of the support frame 1 is provided with a movable plate 4, and the movable plate 4 is movably connected with the support frame 1 through a movable assembly 5. A grid 6 is placed on the top of the movable plate 4, and the Both sides of the support frame 1 are provided with a limit assembly 7 matching the grid 6, the l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap