Potato automatic skewering equipment for barbecue

An automatic and equipment technology, applied in the application, metal processing, food forming and other directions, can solve the problems of low safety of manual threading and inconvenient feeding, and achieve the effect of improving safety, convenient stringing, and convenient and quick production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

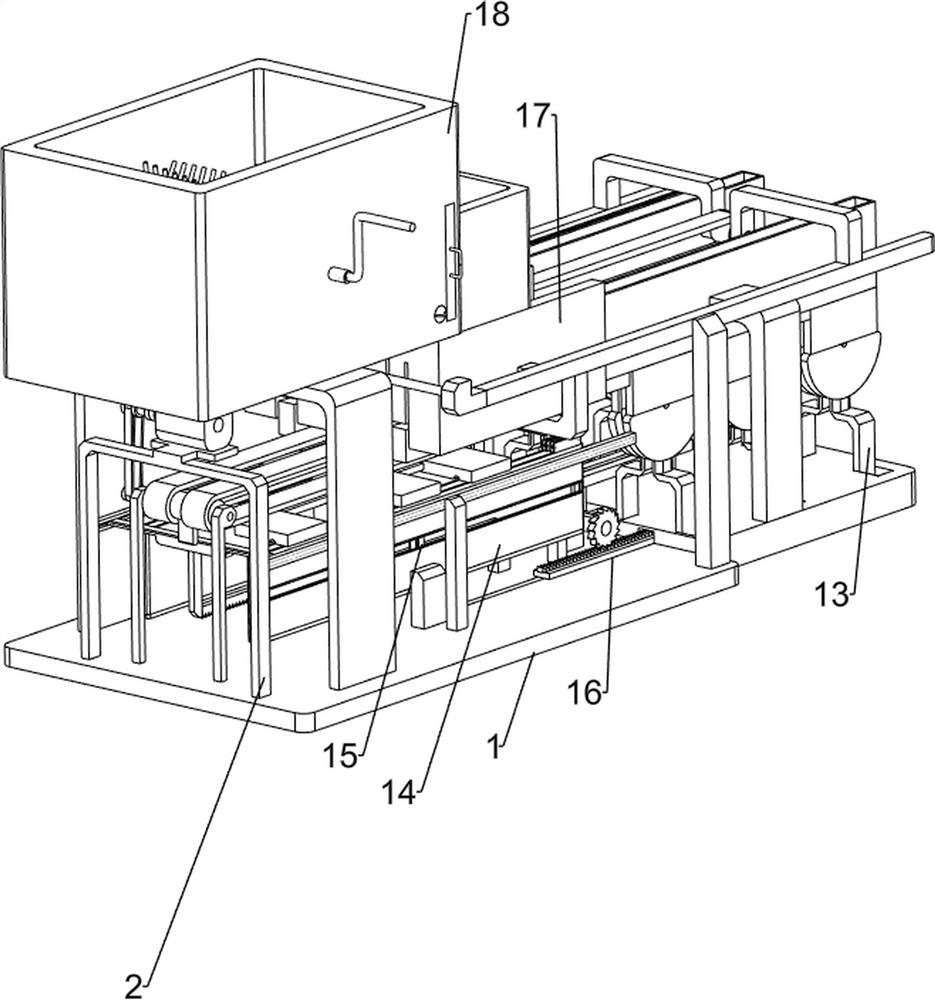

[0082] An automatic potato skewer device for barbecue, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a first support column 2, a motor 3, a second support column 4, a third support column 5, a first rotating shaft 6, a second rotating shaft 7, a first conveyor belt 8, a first belt 9, a first Four supporting columns 10 , a first movable plate 11 and a first telescopic spring 12 , a first supporting column 2 is provided on the left side of the bottom plate 1 , a motor 3 is installed on the top of the first supporting column 2 , and two are provided on the left side of the bottom plate 1 The second support column 4, two third support columns 5 are provided on the right side of the bottom plate 1, the upper inner side of the two second support columns 4 is rotatably connected with the first rotating shaft 6, and the upper inner side of the two third support columns 5 is rotatable A second rotating shaft 7 is connected, a first conveyor belt 8 ...

Embodiment 2

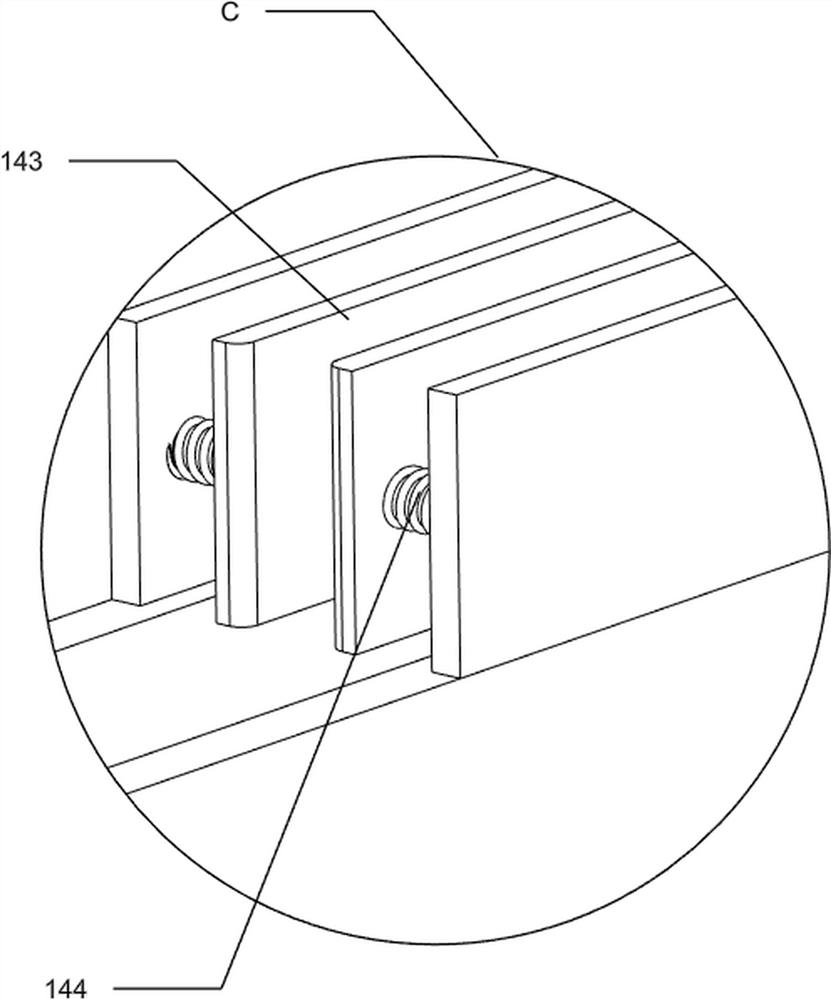

[0085] On the basis of Example 1, as Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, the clamping mechanism 13 includes a fifth support column 131, a blade 132, a second movable plate 133 and a second telescopic spring 134, and two fifth support columns 131 are provided on the upper right part of the bottom plate 1. The fifth support column 131 The inner side of the upper part is provided with a blade 132, and the right part of the bottom plate 1 is slidably provided with six groups of second movable plates 133, two second movable plates 133 in each group. A second telescopic spring 134 is connected between 1 .

[0086] People first place the potato chips in the blade 132. Due to gravity, the potato chips fall between each group of second movable plates 133. After the potato chips are put on by bamboo sticks, people manually move the second movable plate 133 to the outside. The two telescopic springs 134 are compressed, so that the potato string falls down, then t...

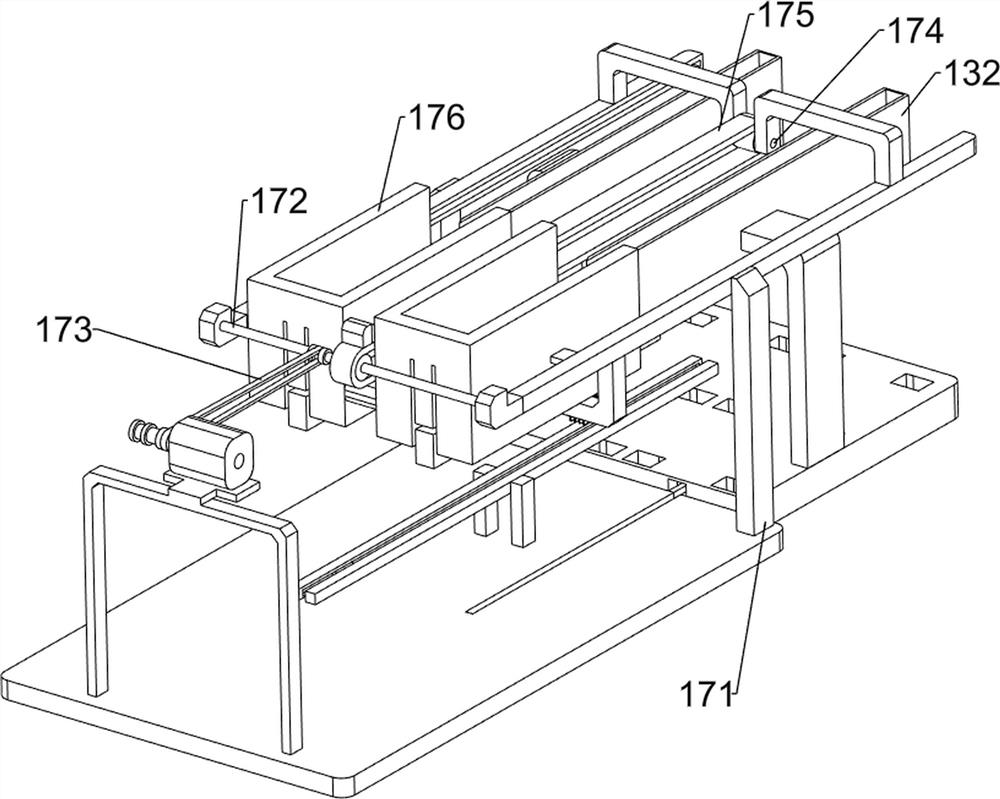

Embodiment 3

[0090] On the basis of Example 2, as figure 1 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, it also includes an upper bamboo stick mechanism 15, the limit mechanism 14 is provided with an upper bamboo stick mechanism 15, and the upper bamboo stick mechanism 15 includes a second compression spring 151, a fourth movable plate 152 and a first movable block 153, Three second compression springs 151 are connected to the inner bottom of the first support plate 141 , and a fourth movable plate 152 is connected to the top of the three second compression springs 151 . The fourth movable plate 152 cooperates with the first support plate 141 , and the first support plate 141 There are two first movable blocks 153 on the outer side of the middle part.

[0091] People can place a large number of bamboo sticks in the first support plate 141. Due to gravity, the bamboo sticks drop down onto the fourth movable plate 152. The movable plate 152 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com