Drum-type construction waste screening equipment

A technology for construction waste and screening equipment, which is applied in the fields of filtering, solid separation, and cleaning of hollow objects, etc. It can solve the problems of shortened service life, long time-consuming, and affecting the use of equipment, so as to achieve enhanced service life, long time-consuming, and increased labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

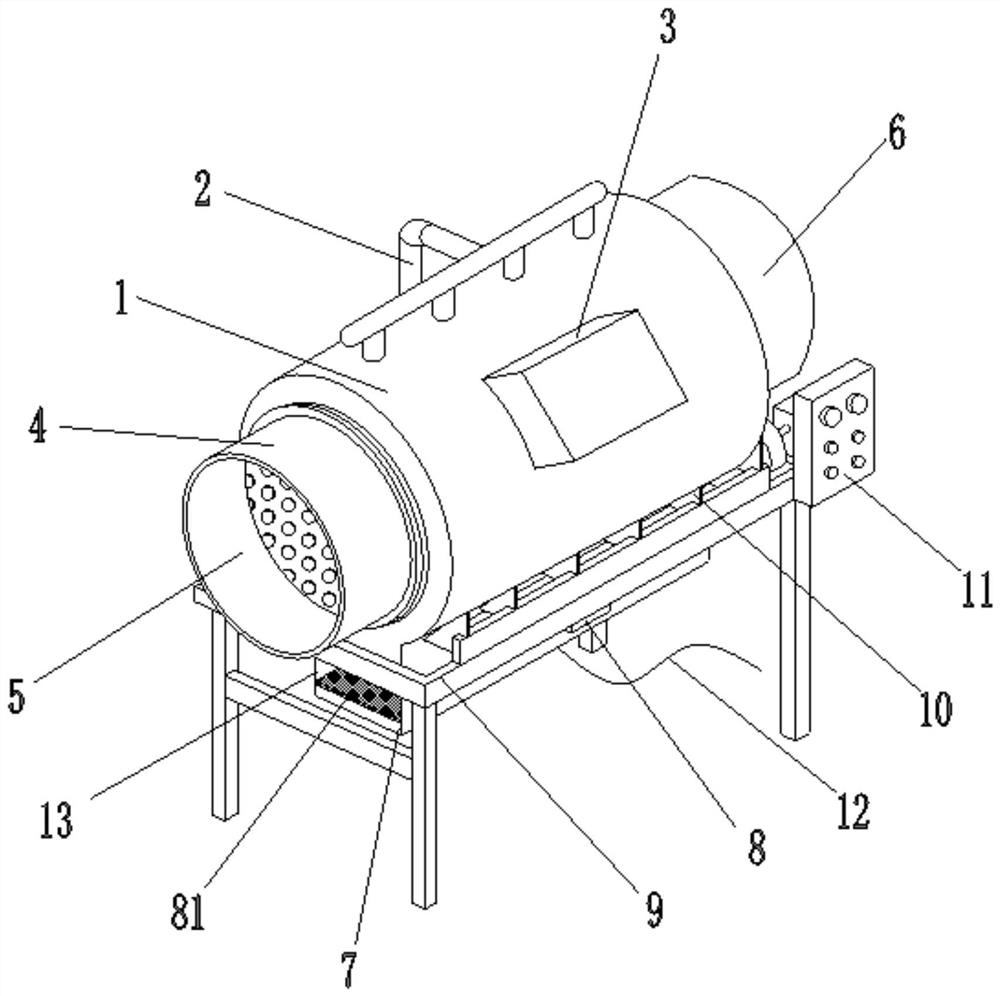

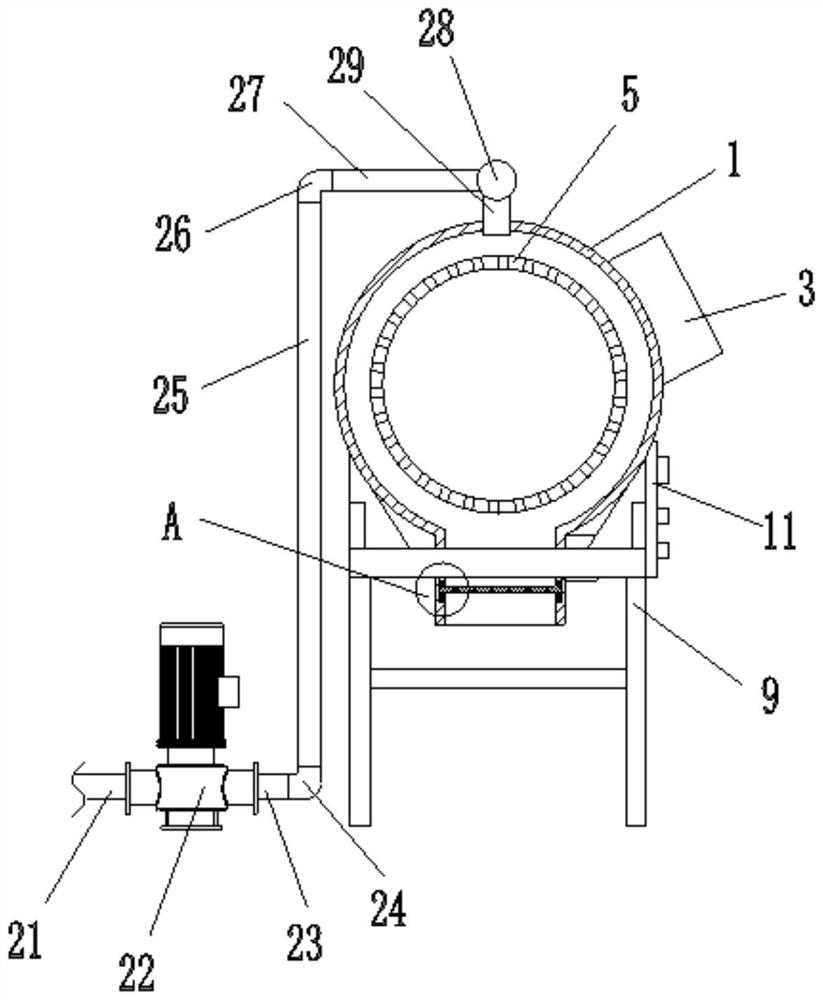

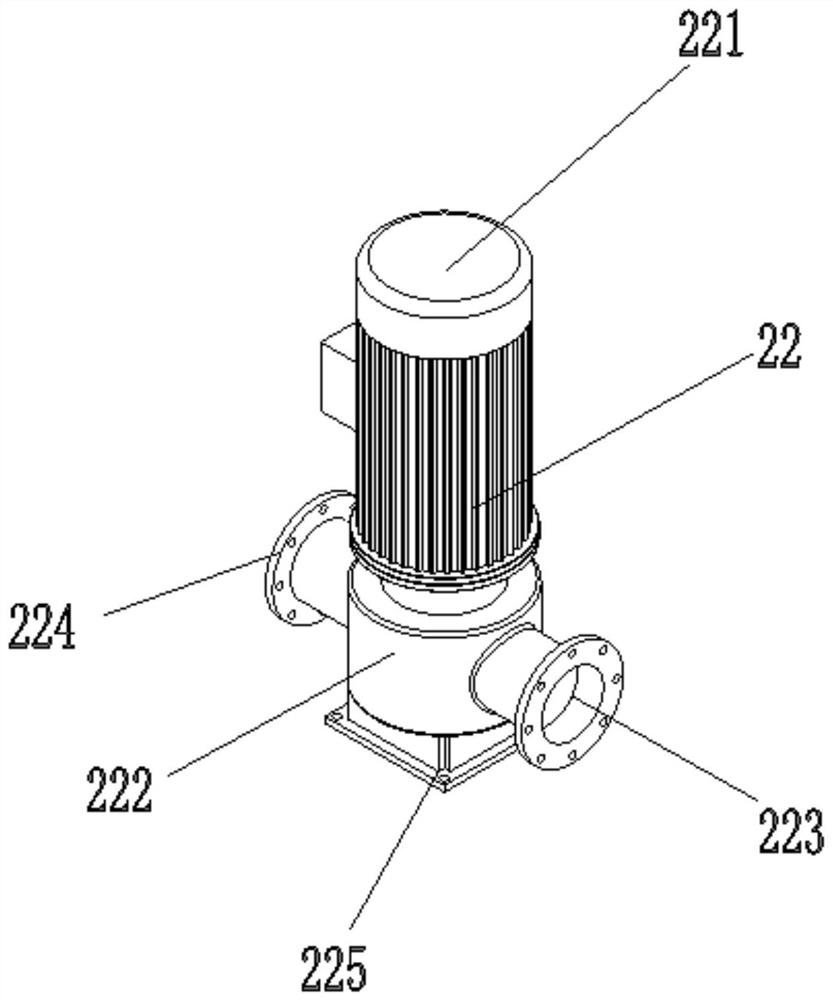

[0035] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 , the present invention provides a drum-type construction waste screening equipment: including a first shell 1, a cleaning device 2, an anti-blocking device 3, a drum 4, a first discharge port 5, a feed port 6, and a second discharge port 7. Auxiliary device 8, bracket 9, triangular fixing block 10, controller 11, power cord 12 and third discharge port 13, the first shell 1 is embedded in the top of the bracket 9, and the left side of the first shell 1 is provided with a cleaning device 2. The left side of the anti-blocking device 3 is fixedly connected to the middle part of the right side of the first shell 1, the first shell 1 is provided with a drum 4 inside, the front side of the drum 4 is provided with a first discharge port 5, and the back of the drum 4 is provided with a feed port 6. The bottom of the first housing 1 is provided with a second outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com