Blank positioning device and positioning method for large die forging

A positioning device and technology for die forgings, applied in the field of material forging, can solve the problems of poor quality of large die forgings, inaccurate positioning, and reduction of die forging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

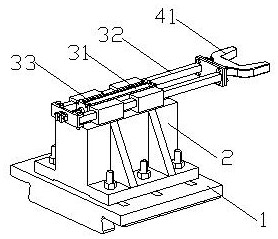

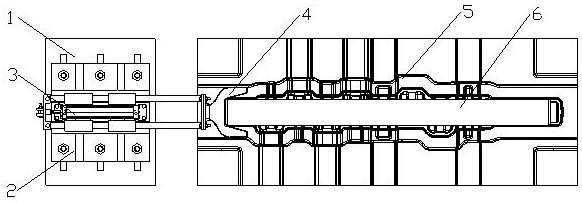

[0027] see figure 1 , a billet positioning device for large die forgings, including a base 1, a support table 2, a telescopic device 3 and a positioning pincer 4. Wherein, the supporting platform 2 is arranged on the base 1 . During specific implementation, the side of the support platform 2 in contact with the base 1 has an outwardly protruding installation boss, so that the section of the support platform 2 has an inverted T-shaped structure. There are several threaded holes on the mounting boss, and strip holes are opened on the base 1 corresponding to the positions of the threaded holes, and the length direction of the strip holes is perpendicular to the length direction of the cylinder 31 . The base 1 and the support table 2 are fixedly connected by bolts passing through strip holes and threaded holes. In this way, the relative position between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com