Clamping device facilitating automatic welding of round pipe

A clamping device and automatic welding technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as low efficiency, and achieve the effect of convenient welding and high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

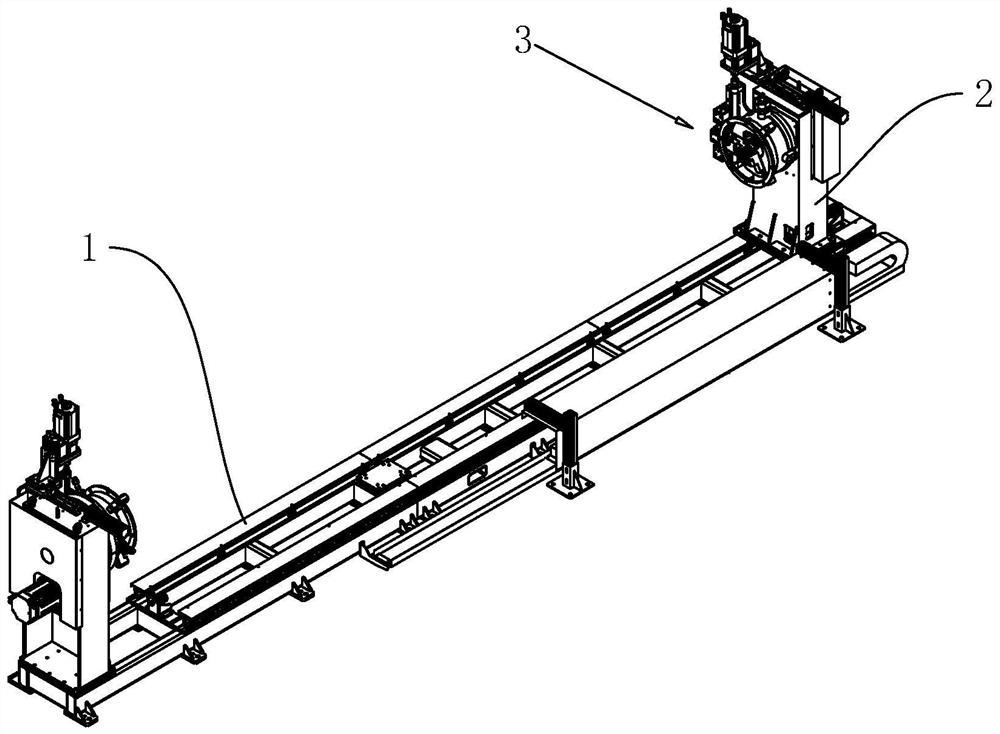

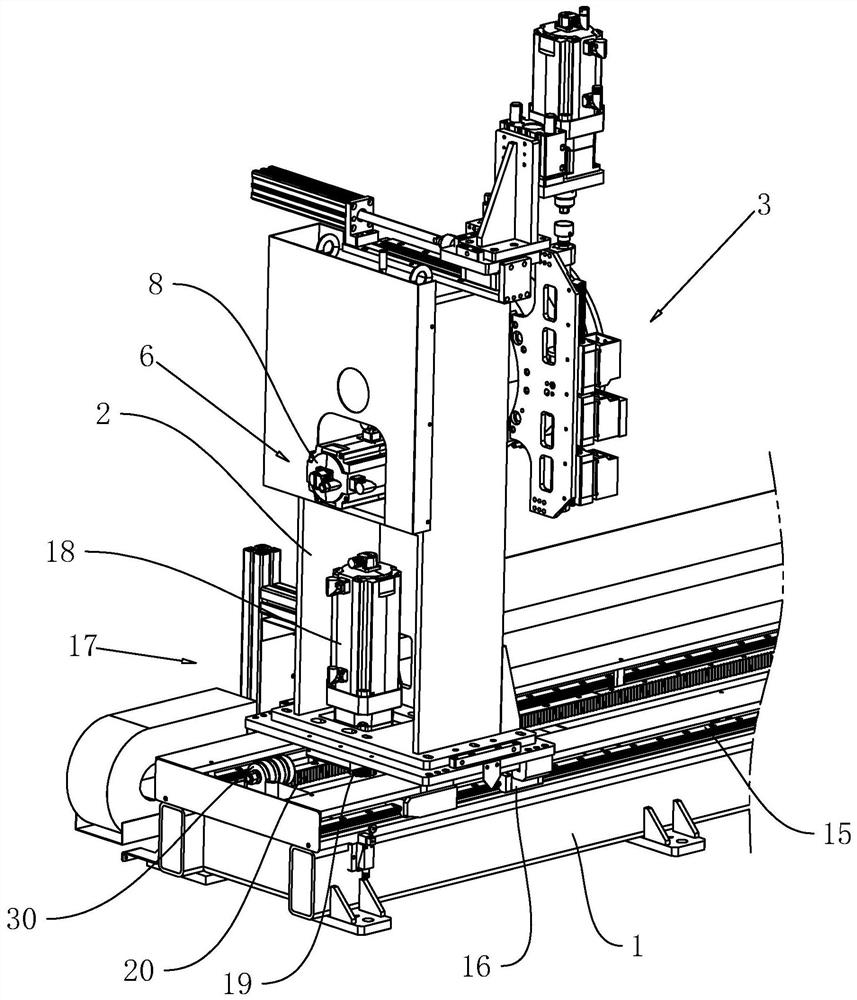

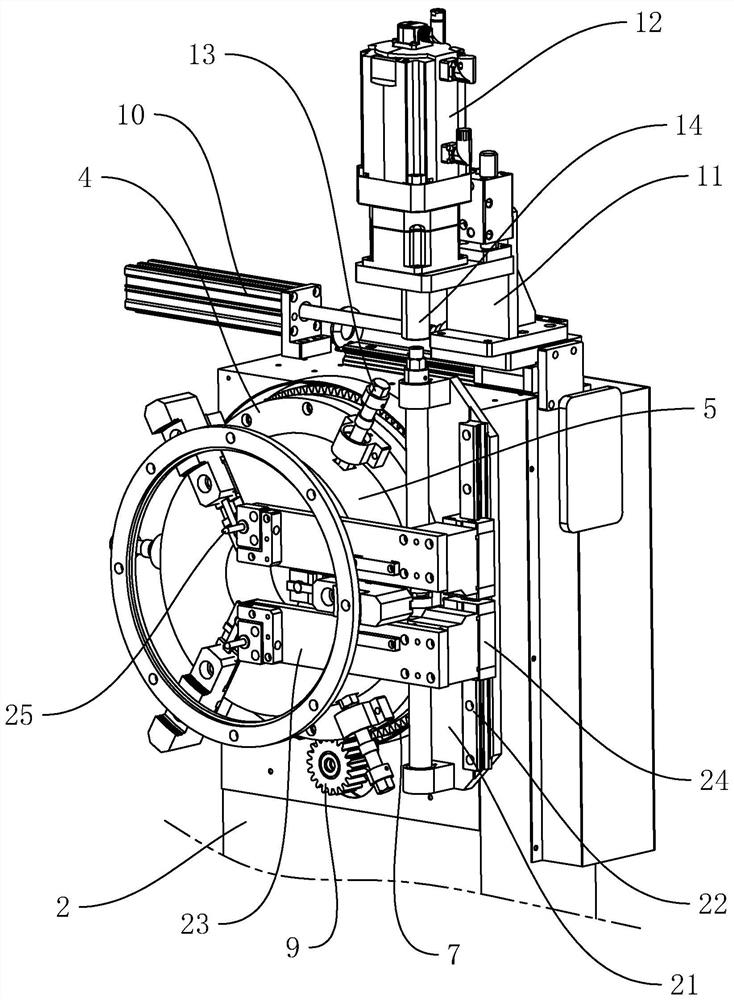

[0031] Contraction below Figure 1-4 Further detailed description of the present application.

[0032] In this application example, it is disclosed a clamping device 3 that facilitates the automatic welding of the circular tube.

[0033] Refer figure 1 A clamping device 3 that facilitates the automatic welding of the round tube, including the base 1, both ends of the base 1, and the mounting seat 2 is provided, and the mounting seat 2 is provided with a clamping device 3 for clamping a circular tube, welding round tube. In the process, the round tube is held on one of the clamping device 3 at one end, and the other end is sandwiched on another clamping device 3.

[0034] Refer figure 2 One of the mounting seats 2 slides on the base 1, so that the round tube of different lengths between the two holding means 3 can be mounted, and both sides of the base 1 are provided with a first rail 15, the first guide rail 15. For the straight rail, two first slider 16 is fixed to the bottom of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap