Computer machining and assembling device

An assembly device and computer technology, applied in the computer field, can solve problems affecting work efficiency, effort, and time-consuming, and achieve the effects of increasing the contact area, large guiding area, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

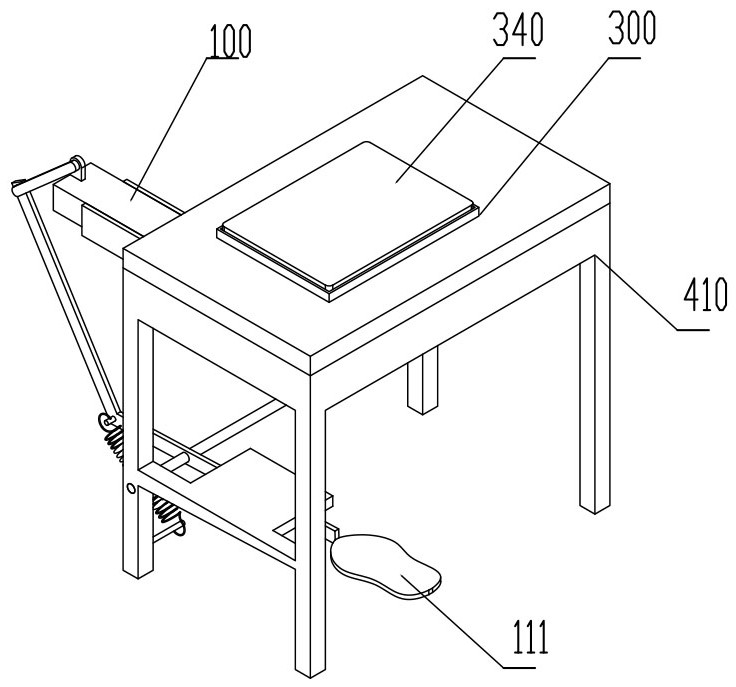

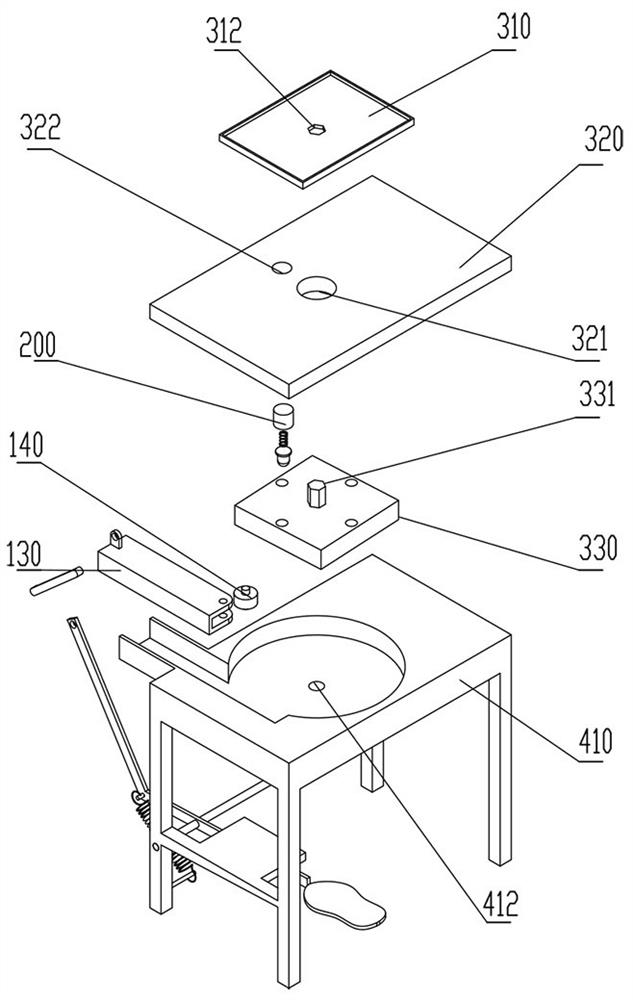

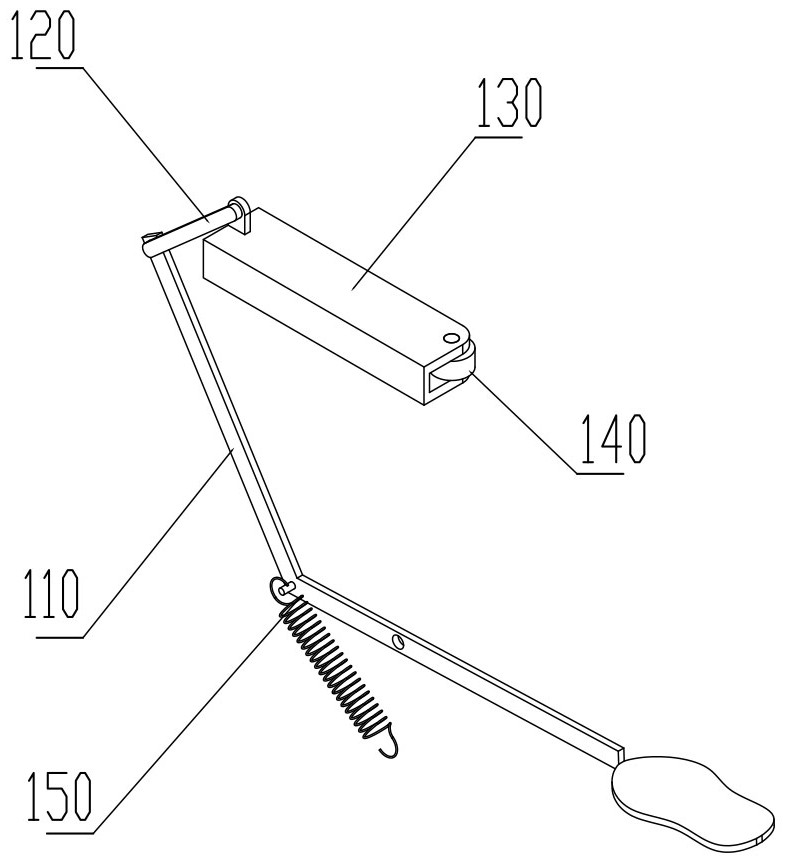

[0026] A computer processing and assembling device, including a driving device 100, a positioning device 200, a rotating device 300, and an operating table 410, the driving device 100 includes a driving rod 110, a connecting rod 120, a slider 130, a roller 140, a tension spring 150, and a positioning device 200 Including positioning and positioning cap 210, pin 220, spring 230, rotating device 300 includes positioning device 200, hopper 310, operating surface 320, rotating table 330, said operating table 410 has an inner cavity 411 in the middle, and a rotating shaft hole in the middle of the inner cavity 411 412, the left side of the console 410 has a chute 413, the bottom of the console 410 has four support legs 417, the bottom of the two support legs 417 on the rear side has a shaft 414 connecting the two support legs 417, and the bottom of the rear supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com