Small flexible driving snakelike mechanical arm

A mechanical arm and flexible transmission technology, applied in the field of robotics, can solve the problems of rigid motion form, large structure size, and poor motion flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

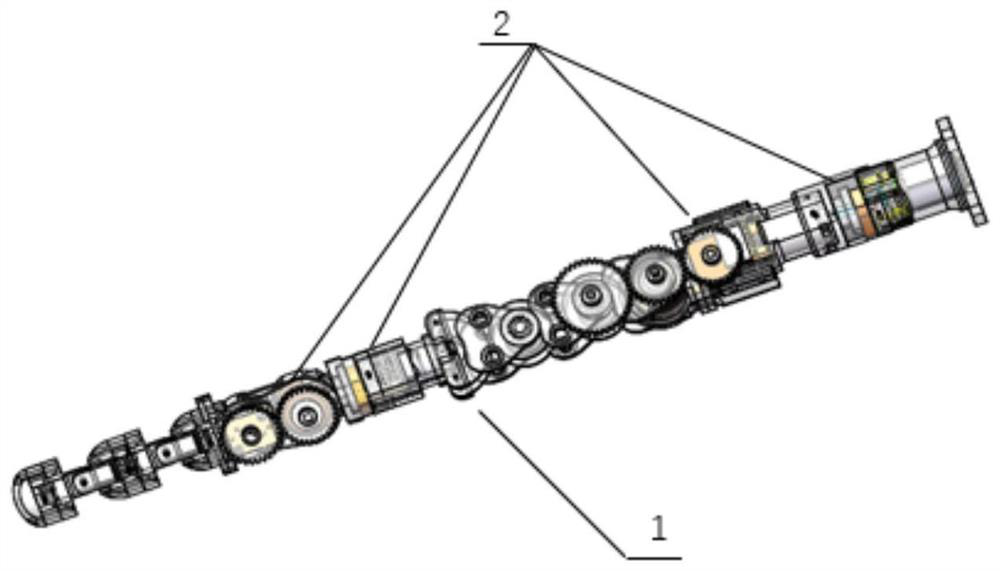

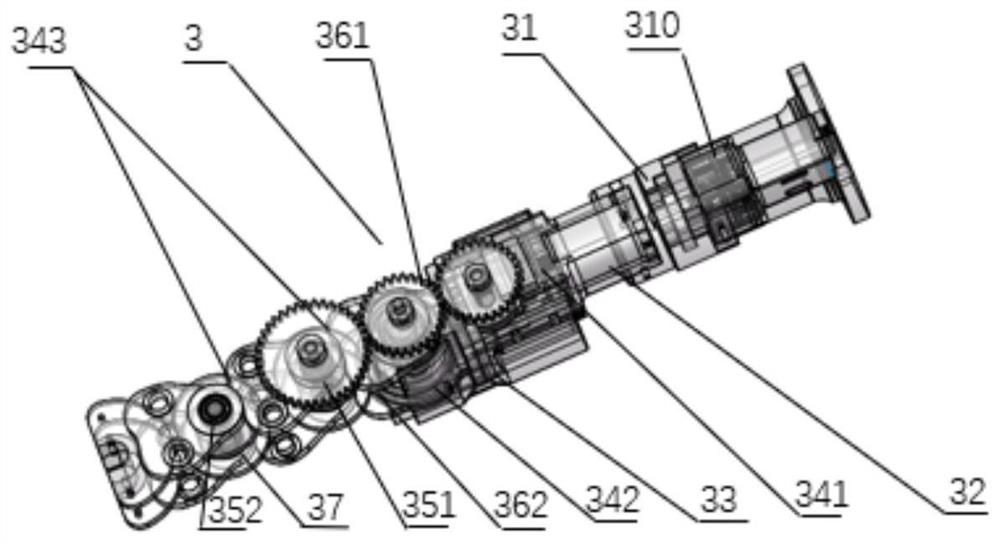

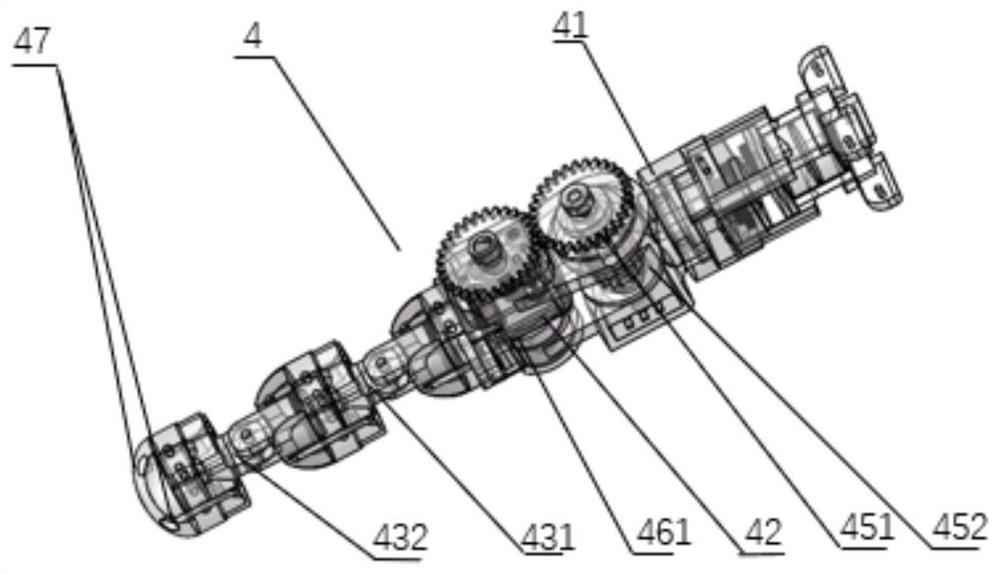

[0027] Example: A small flexible drive snake-like robotic arm, please refer to figure 1 , including the robot arm body 1 and the drive system 2 . Specifically, the driving system is distributed in the main body of the mechanical arm to drive the movement of the entire mechanical arm. The mechanical arm body 1 includes a rear arm body 3 each having a rotary joint and two yaw joints ( figure 2 ) and forearm body 4 ( image 3), both of which provide a large range of motion space for the manipulator as a whole. The rotary joints 31 and 41 in the rear arm body 3 and the forearm body 4 are directly driven by the drive source, which ensures that the mechanical arm has a certain load capacity, and the two sets of yaw joints are indirectly driven. The driving source 1 32 and the driving source 2 33 in the rear arm body 3 are placed at the rear end of the yaw joint 1 351 structure, the driving source 1 32 is connected to the gear transmission 361 through the support 341, and the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com