Incisor for insulating tape

An insulating tape and incision technology, which is applied in the field of incision devices, can solve the problems of reduced adhesiveness of insulating tape, uneven winding of tape, sore wrists, etc., and achieve the effects of prolonging service life, improving repair efficiency, and improving light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

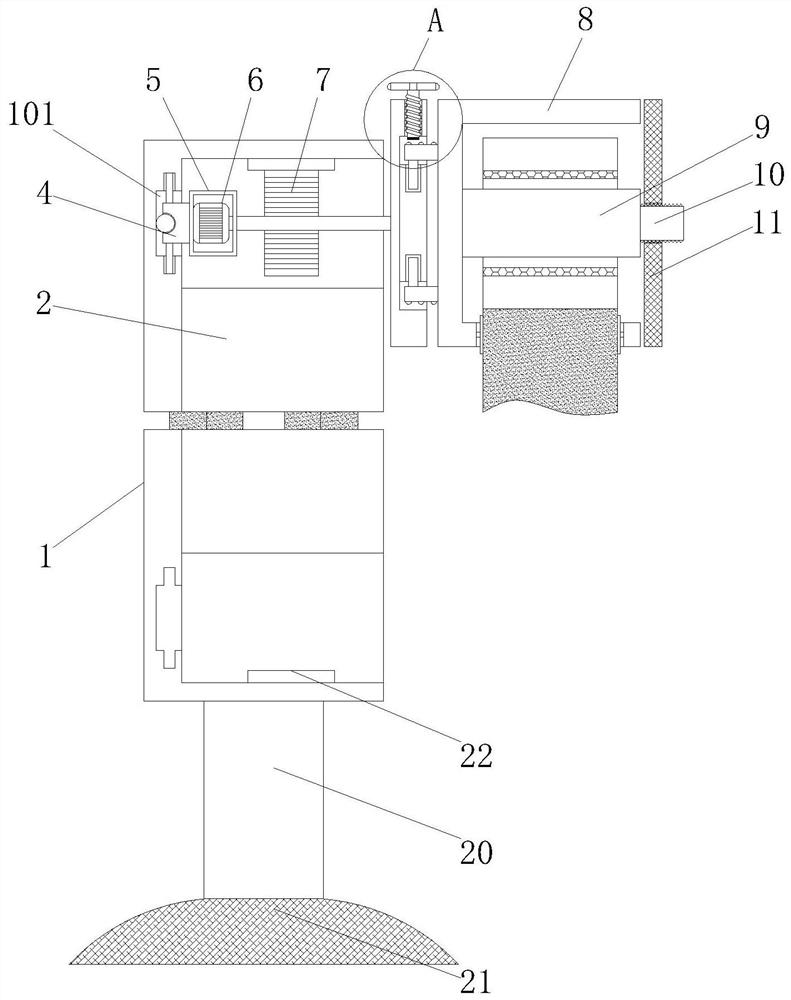

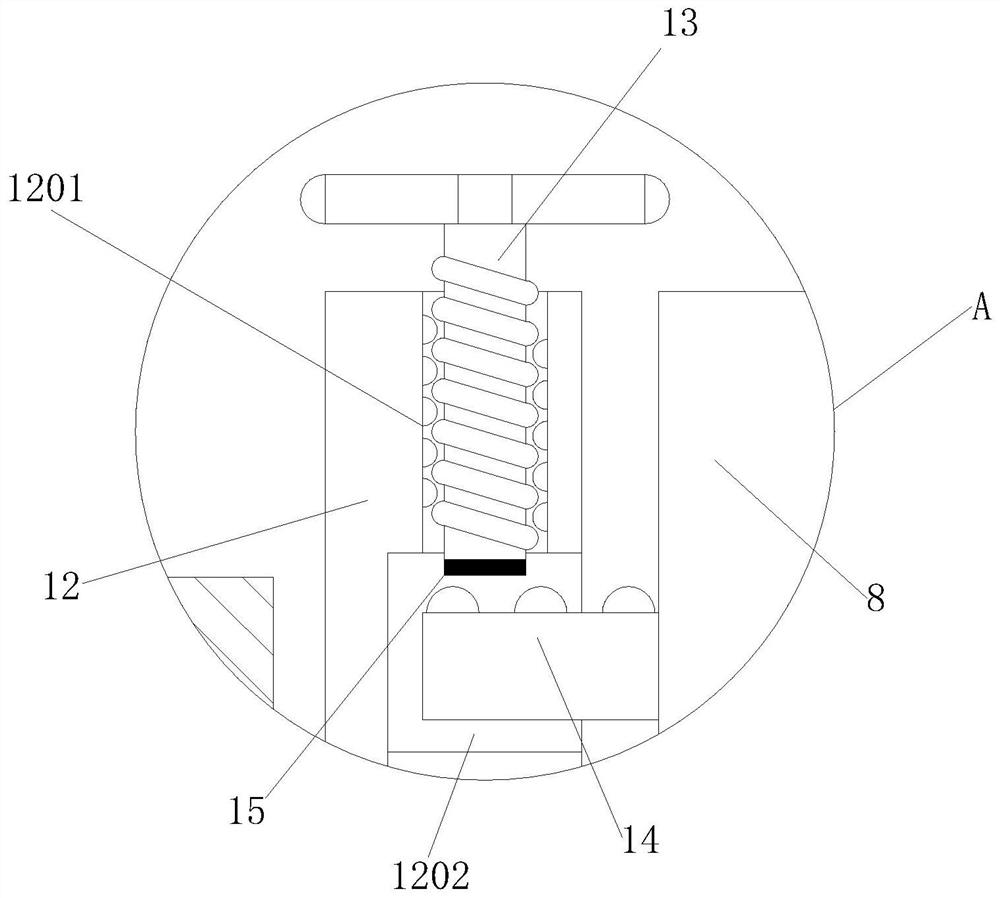

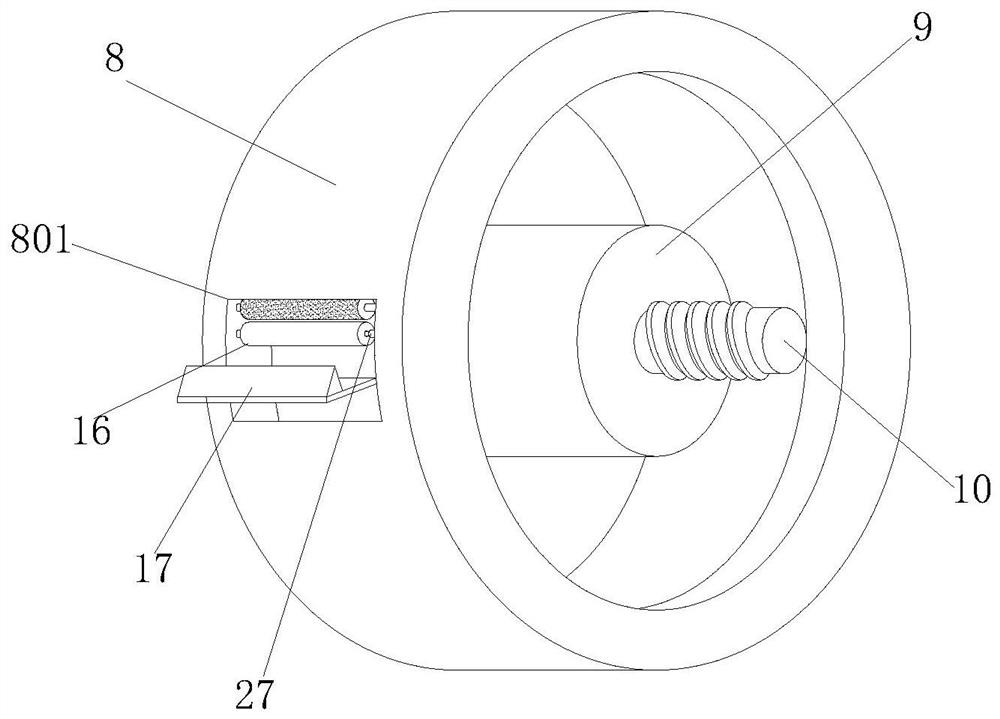

[0043] see figure 1 and Figure 4 , an incisor for insulating tape, comprising a semi-circular cylinder 1, the semi-circular cylinder 1 is provided with two semi-circular cylinders 1 and the semi-circular cylinder 1 is connected by a hinged manner, the semi-circular cylinder 1 is The inner side of the cylinder 1 is fixedly connected with the arc-shaped plate 2, and the inner side of the semi-circular cylinder 1 is provided with an annular chute 101, and a slider 4 is slidably connected in the annular chute 101. A motor box 5 is fixedly connected at one end, a circular hole is opened on one side of the motor box 5, a micro motor 6 is fixedly connected in the motor box 5, and the output end of the micro motor 6 is fixedly connected with a drive shaft, so One end of the drive shaft passing through the circular hole is fixedly connected with the drive gear 7 and the adapter plate 12. One side of the adapter plate 12 is provided with an annular adapter groove 1202, and the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com