Structure repairing and reinforcing method for concrete chimney and cooling tower

A concrete and cooling tower technology, which is applied in building maintenance, building construction, construction, etc., can solve problems such as unsatisfactory repair and reinforcement effects, and achieve the effect of reducing performance and structural stability and excellent carbonation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0117] Preferably, the preparation method of the micron-sized diamine@MOF particles comprises: adding aluminum nitrate and 4,4'-biphenyldicarboxylic acid to the Disperse evenly in water, heat up to 160-200°C, then adjust the pH of the resulting solution to 2-4, and keep it warm for 5-10 hours; after the reaction, filter, wash, dry and pulverize to obtain micron-sized aluminum MOF particles ;Immerse aluminum MOF particles in a diamine solution (isophoronediamine, m-phenylenediamine or m-xylylenediamine), let it stand for 2-4h for adsorption, and centrifuge to obtain micron-sized diamine@MOF particles.

[0118] The concrete grouting liquid includes A component and B component with a mass ratio of (4-4.5): (1.5-2.0), wherein: the A component includes the following components in mass percentage: bismuth with Mw<700 Phenol-A-epichlorohydrin resin 60-68%, glycidyl 12-14 alkyl ether 10-20%, 1,6-hexanediol diglycidyl ether 10-20%, bisphenol F with Mw<700 Epoxy resin 10-20%, 3-(2,3-e...

Embodiment 1

[0121] The repair depth is not greater than 5cm: the repair and reinforcement plan specifically includes the following steps:

[0122] S1: Eliminate and clean the loose concrete at the repaired area until it reaches a solid base surface, ensuring that the treated base surface is solid and clean, free of loose mortar particles, floating layers, fatty substances, cement mortar skins, and uncompacted concrete;

[0123] S2: Derusting the steel bars;

[0124] S3: Use base surface repair mortar for repair, and ensure that the thickness of the protective layer for steel bars is not less than 2cm.

Embodiment 2

[0126] The repair depth is greater than 5cm and less than or equal to 1 / 3 of the structural thickness: the repair and reinforcement plan specifically includes the following steps:

[0127] S1: Eliminate all loose concrete in the repaired area until the solid base surface, and ensure that the treated base surface is solid and clean, free of loose mortar particles, floating layers, fatty substances, cement mortar skins, and uncompacted concrete;

[0128] S2: Derusting the steel bars;

[0129] S3: Hanging reinforcement mesh, the mesh adopts Φ3@60 reinforcement mesh to ensure that the reinforcement mesh is fixed on the vertical reinforcement of the original structure;

[0130] S4: Use base surface repair mortar to repair, and ensure that the thickness of the protective layer on the steel bar is not less than 2cm;

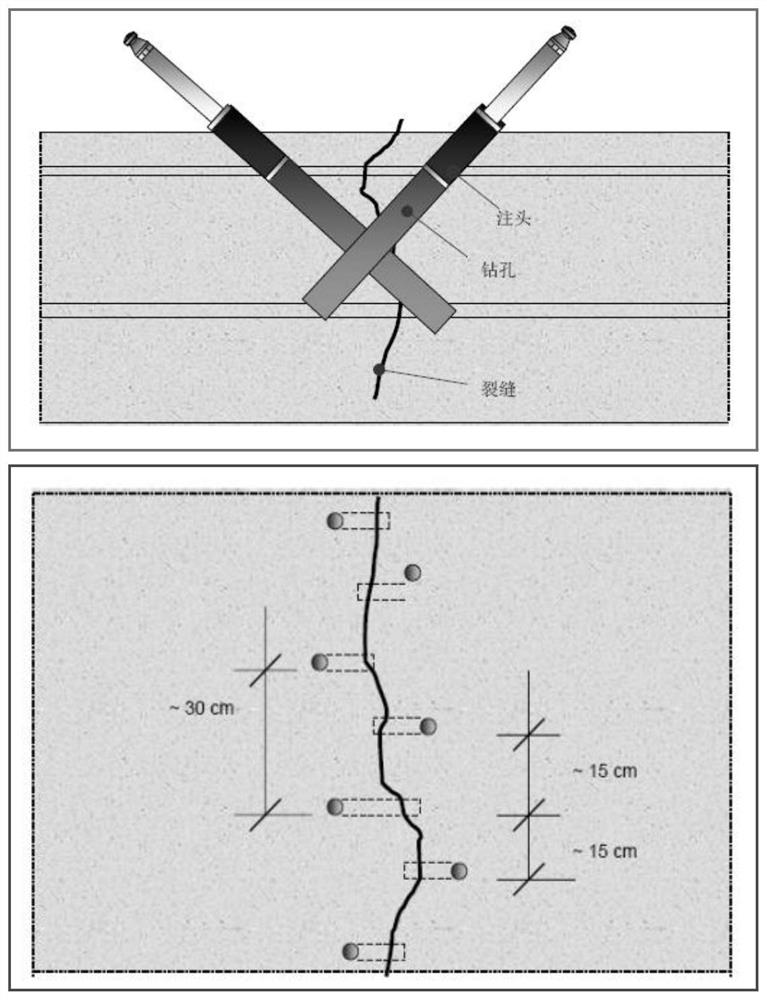

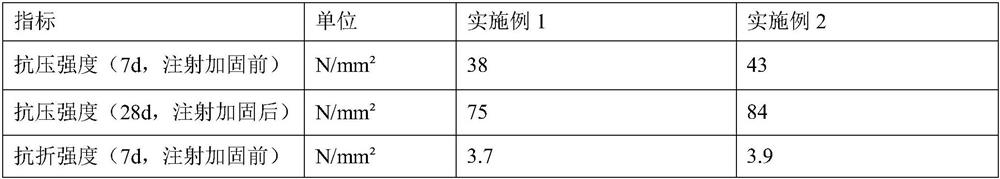

[0131] S5: After 7 days of natural curing, the repaired part is reinforced with concrete grouting fluid. The glue injection holes are arranged in a plum blossom shape....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com