Steel pipe surface defect detection device and detection method

A defect detection and steel pipe technology, applied in measuring devices, optical testing of defects/defects, material analysis by optical means, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

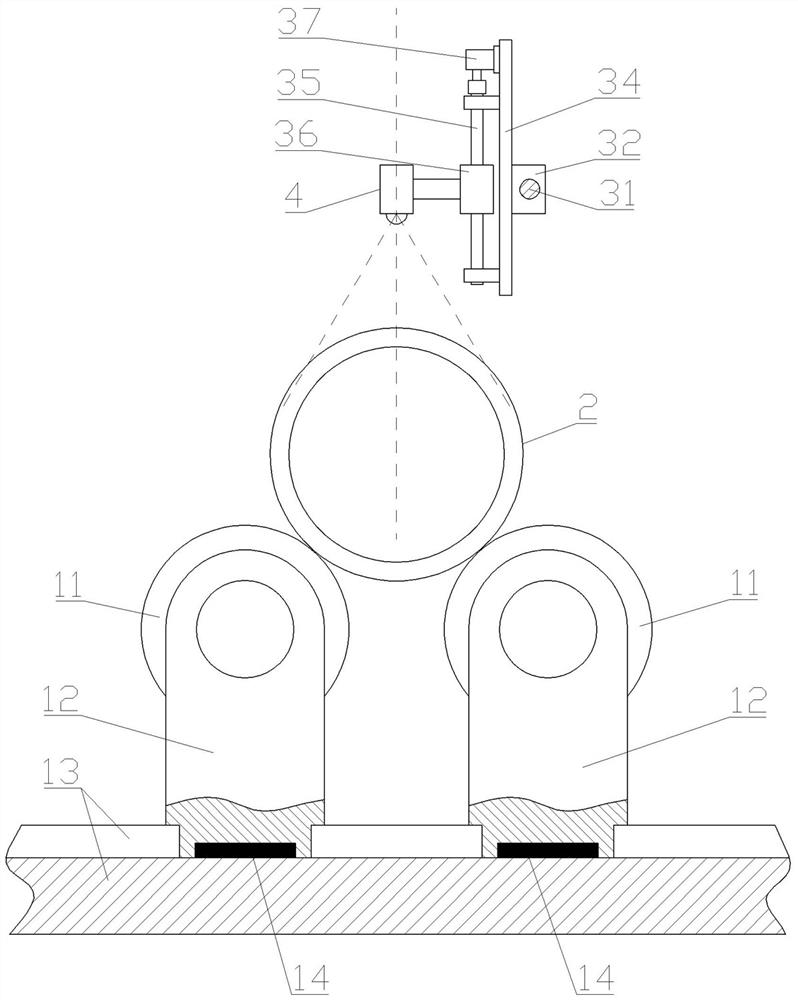

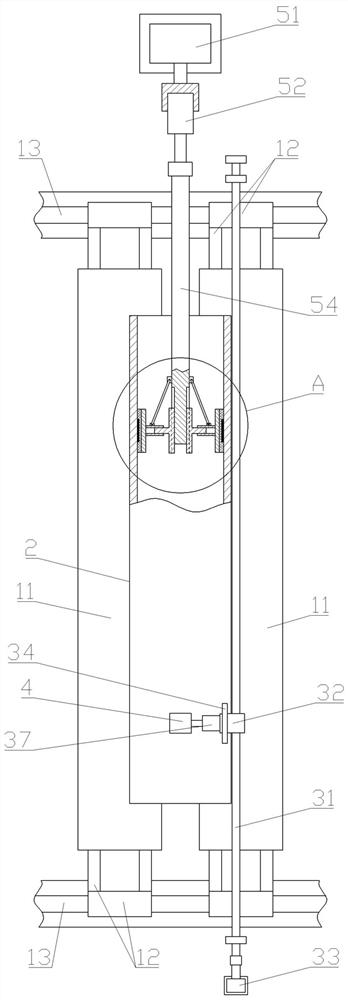

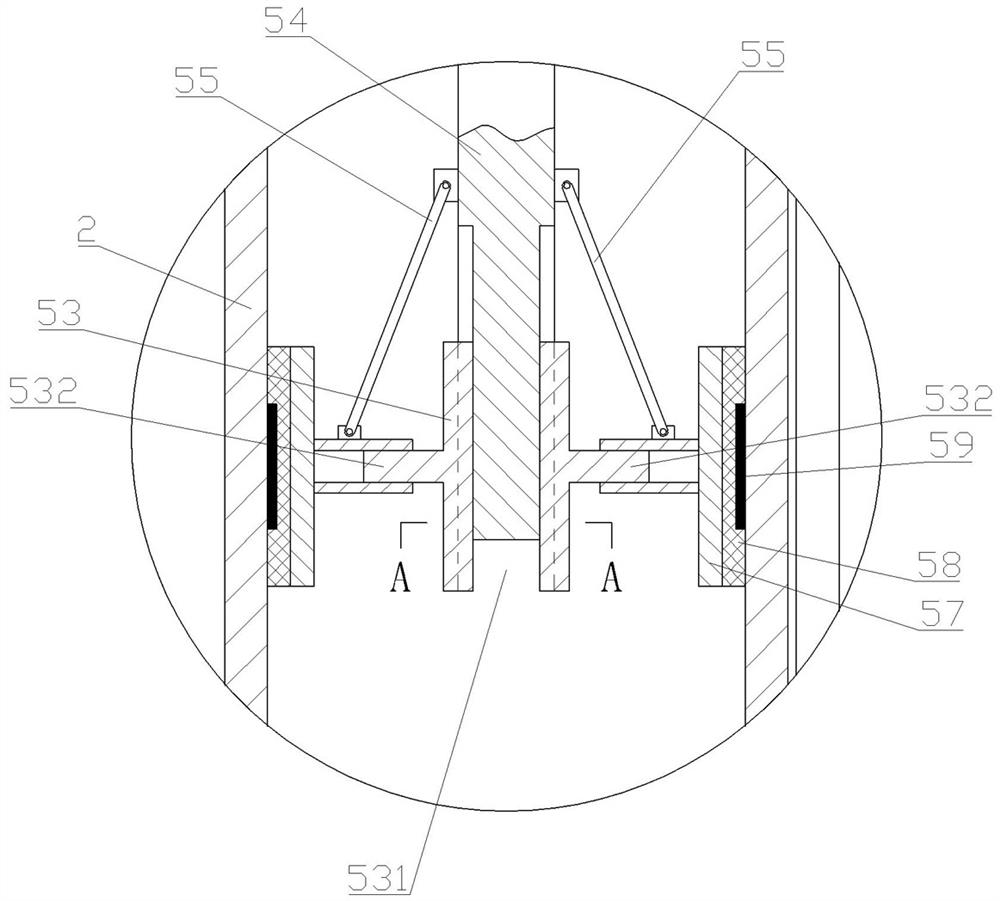

[0039] like Figure 1-5 As shown, the steel pipe surface defect detection device includes a steel pipe idler mechanism, a steel pipe 2, a camera movement control mechanism, a camera 4, a steel pipe clamping and rotating mechanism, and a main control computer 6.

[0040] The steel pipe idler mechanism includes a roller 11 , a bearing seat 12 , a slide rail 13 and an electromagnet 14 . The number of rollers 11 is two, and the two rollers 11 are arranged parallel to each other and horizontally, and the two ends of the rollers 11 are movably installed on the supporting base 12 through bearings. The slide rail 13 is fixedly installed on the ground, and is located at the lower end of the support base 12, and is slidingly matched with the support base 12. The electromagnet 14 is embedded in the bottom of the support seat 12 and faces the slide rail 13. When the electromagnet 14 is energized, the support seat 12 and the slide rail 13 are fixed as one. When the electromagnet 14 is pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com