Control box and electric lifting table

A control box and control circuit board technology, which is applied to tables, electrical components, printed circuit board sockets, etc., can solve the problems of low yield, inability to meet fast assembly, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

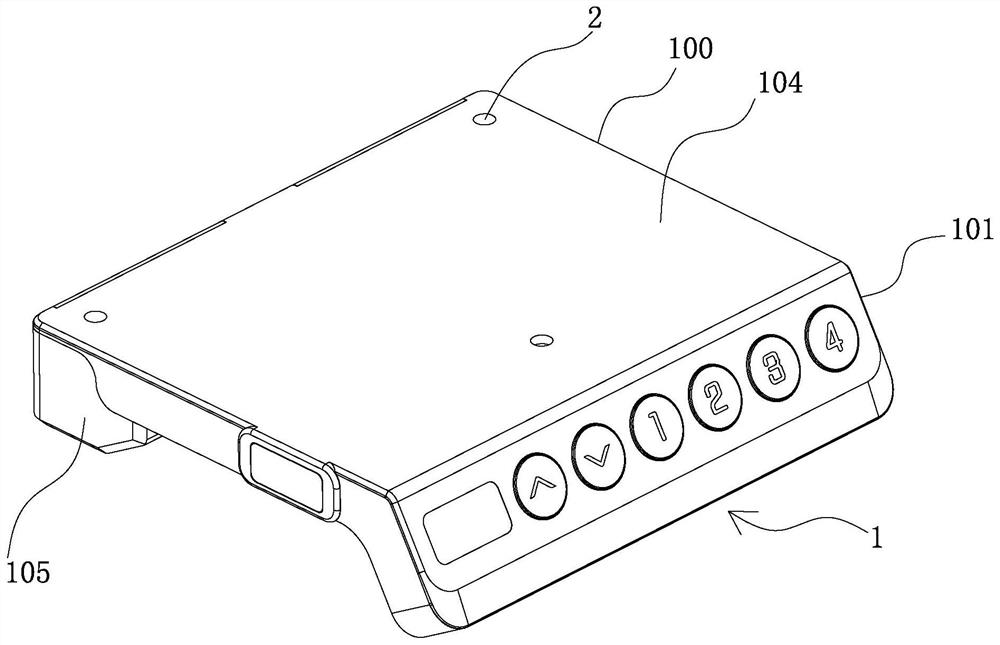

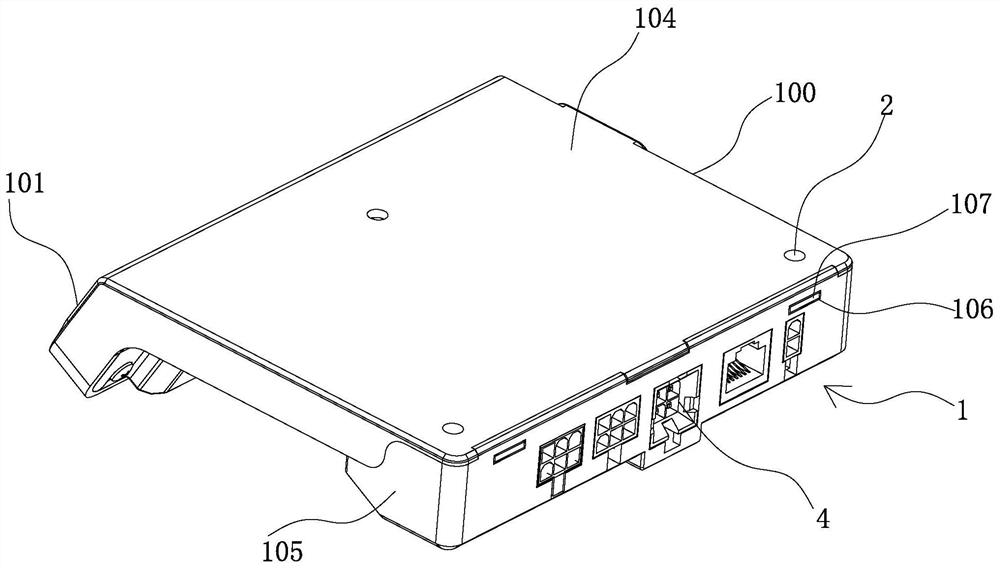

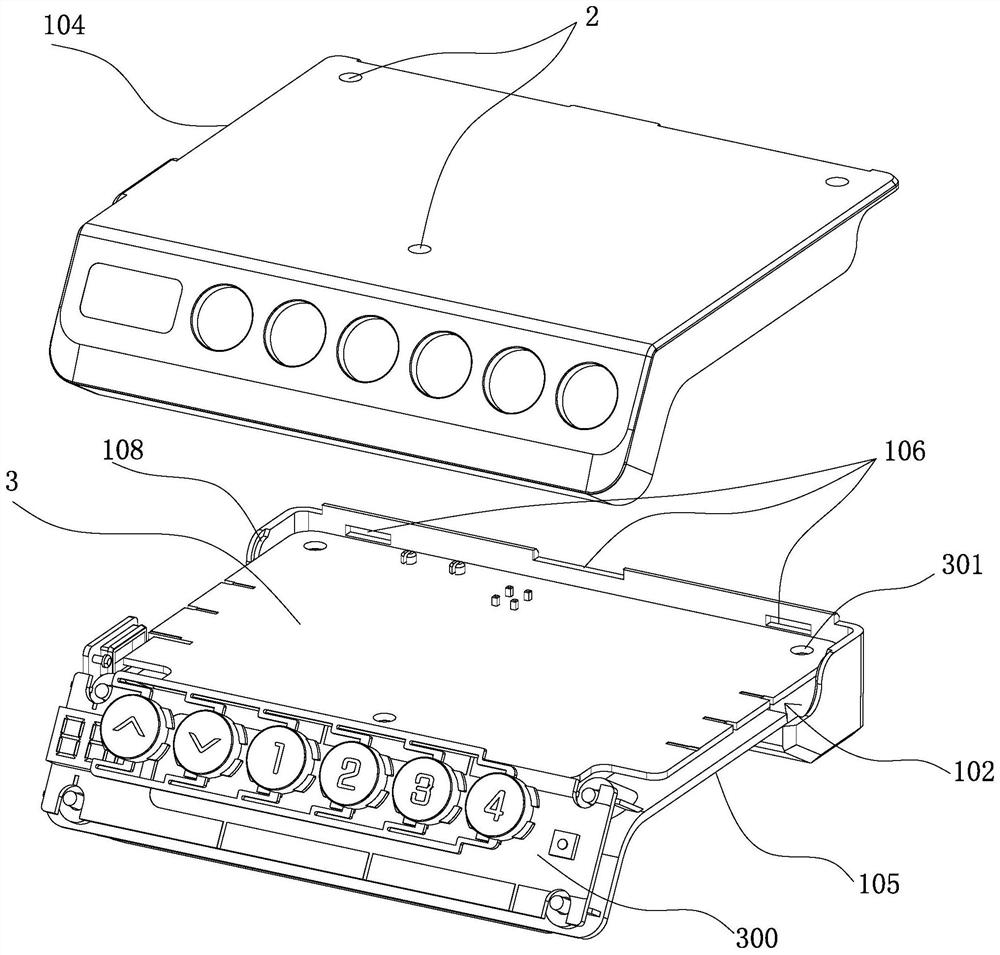

[0031] see Figure 1 to Figure 5 shown;

[0032] The present invention is a control box, which includes a box body 1, which has a straight side portion 100 connected to the bottom of the table and an inclined portion 101 that is inclined downward and forms a certain angle with the straight side portion 100. The inclined portion 101 It is arranged on the side of the box body 1 close to the user. The straight side part 100 of the box body 1 is provided with a first installation space 102, and the inclined part 101 is provided with a second installation space 103; The side part 100 is provided with a plurality of connection holes 2 extending along the thickness direction of the box body 1 and respectively penetrating through the top and bottom of the straight side part 100; the first control circuit board 3 is arranged in the first installation space 102, and the first control circuit board 3 The circuit board 3 is provided with a through hole 301 corresponding to the connection...

Embodiment 2

[0039] see Figure 6 ~ Figure 7 shown;

[0040] A control box of the present invention, it also includes two slots 113 on the two side walls of the first end of the upper case 104, and two slots 113 on the two side walls of the first end of the lower case 105. When the upper casing 104 and the lower casing 105 are closed, the two sockets 114 are plugged into the two slots 113. Two first clamping holes 115 are provided on the two side walls of the straight side portion 100 of the upper housing 104 , and two first clamping holes 115 are provided on the two side walls of the straight side portion 100 of the lower housing 105 . The first clamping block 116 that matches and engages; the edge of the inclined part 101 of the upper housing 104 is provided with at least one second clamping hole 117, and the edge of the inclined part 101 of the lower housing 105 is provided with the second clamping hole 117 The second clamping block 118 is matched with the clamping joint. When the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com