Thighbone far-end outer side bone fracture plate

A bone plate, distal technology, applied in the field of medical devices, can solve the problems of knee joint instability, excessive stripping, slow recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

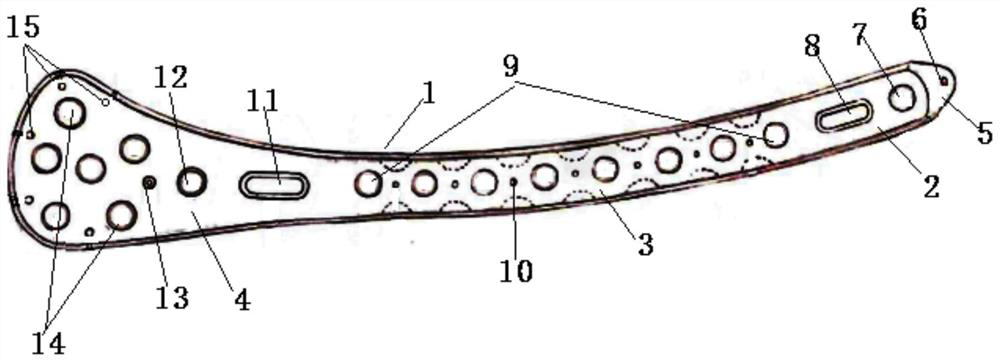

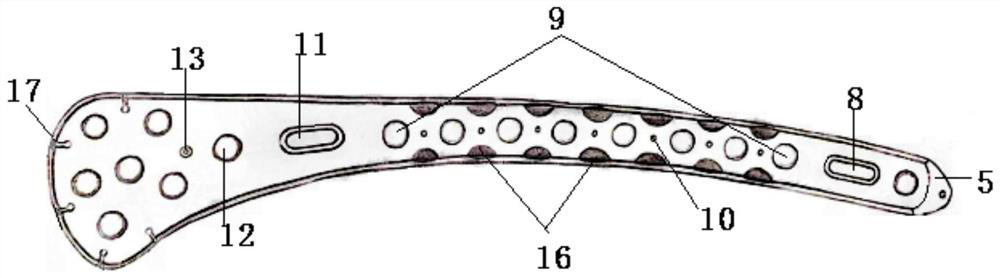

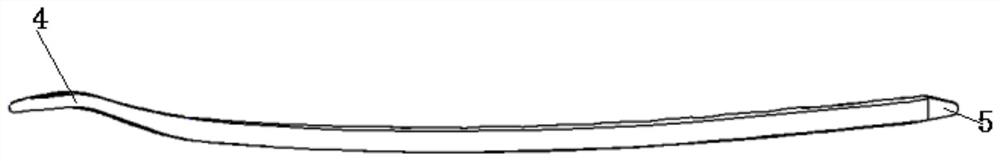

[0019] Such as Figure 1-Figure 3 A distal femur lateral bone plate is shown, which includes a bone plate body 1 with a length of 15-35 cm, a width of 1.5-3.5 cm, and a thickness of 0.3-0.6 cm. The bone plate body 1 is divided into a proximal segment 2 , the middle section 3 and the distal section 4, the proximal section 2 and the middle section 3 are arc-shaped structures, which are the same as the curvature of the anterior arch of the femur, the right end of the proximal section 2 is a blunt triangular structure 5, and the far The end section 4 gradually becomes thinner and twisted from right to left, and is concave and inclined inwardly. Kirschner wire holes 6, proximal locking holes 7 and sliding holes 8, the proximal Kirschner wire holes 6 are located on the blunt triangular structure 5, and the middle section 3 is provided with a plurality of middle locking holes 9 adjacent to the middle A middle Kirschner wire hole 10 is provided between the locking holes 9, and the di...

Embodiment 2

[0021] Such as Figure 1-Figure 3 A distal femur lateral bone plate is shown, which includes a bone plate body 1 with a length of 15-35cm, a width of 1.5-3.5cm, a thickness of 0.3-0.6cm, and a smooth curved surface structure at the edge. 1 is divided into a proximal section 2, a middle section 3 and a distal section 4. The back of the bone plate body 1 is provided with a plurality of arc-shaped grooves 16, and the arc-shaped grooves 16 are symmetrically distributed on both sides of the middle section 3. side, which is beneficial to disperse the stress, and at the same time reduce the impact of the bone plate body 1 on the periosteal blood supply. The proximal section 2 and the middle section 3 are arc-shaped structures, which are the same as the curvature of the anterior femoral arch, with a width of 12 mm and a thickness of 6 mm. The right end of the proximal section 2 is in a blunt triangular structure 5, and the distal section 4 gradually becomes thinner and twisted from ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com