Precise positioning clamp holder for batch part machining

A technology for parts processing and precise positioning, which is applied in the field of precise positioning grippers for parts processing, can solve problems such as inaccurate positioning, large part processing errors, and low processing efficiency, and achieve the effects of precise positioning and reduced processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

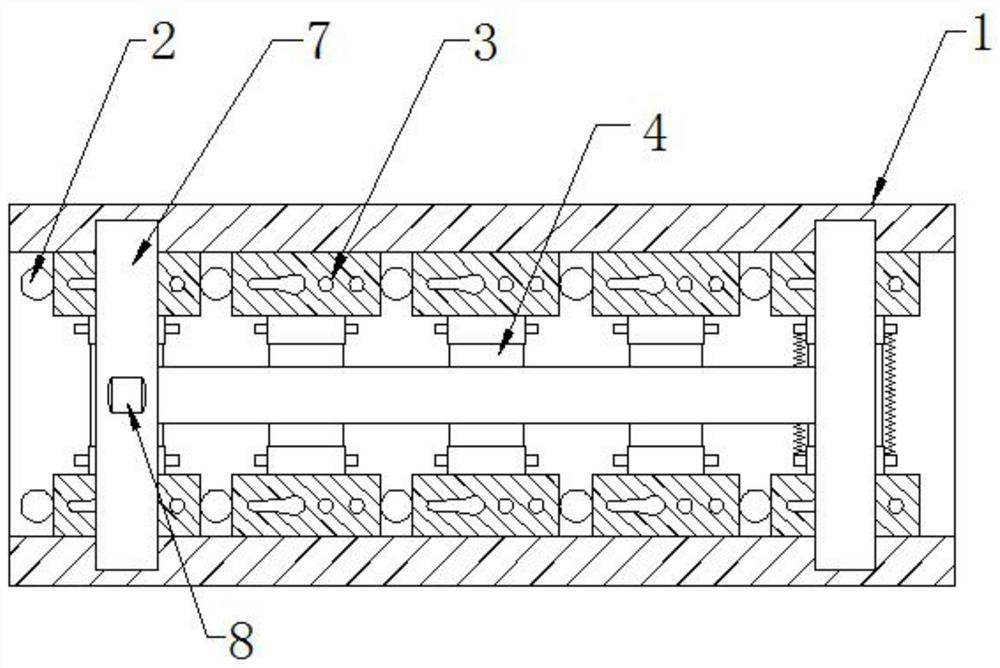

[0020] see figure 1 , the present invention provides a technical solution: a batch-capable precision positioning gripper for parts processing, including a tooling body 1, the tooling body 1 is in the shape of a groove, and positioning Columns 2 and adjacent positioning columns 2 are provided with processed products 3 , correspondingly between the processed products 3 is provided with a limit device 4 , the front and rear end surfaces of the limit device 4 are attached to the opposite surfaces of the processed products 3 , and the left and right sides of the main body of the tooling 1 No fixed plate is provided to ensure that the processed product 3 is conveniently taken out.

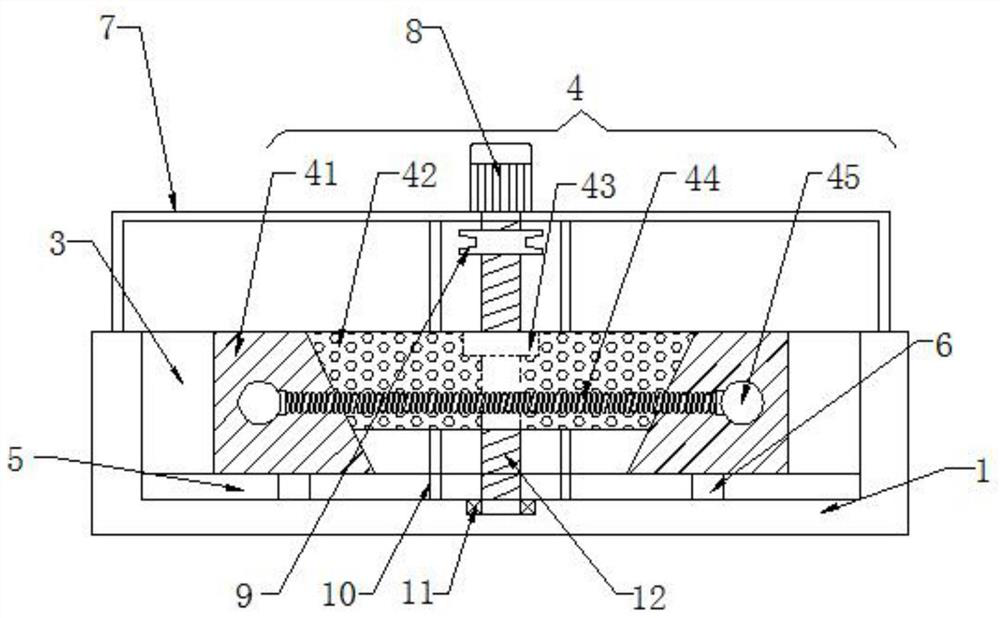

[0021] see figure 2 , the limit device 4 includes a positive trapezoidal block 41, an inverted trapezoidal block 42, a bolt hole 43, a spring 44 and a connecting column 45, and the inner cavity of the frock main body 1 is provided with two sets of positive trapezoidal blocks 41 with the same structure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com