Design Method of Converter Bottom Transition Brick

A converter bottom and bottom brick technology, which is applied in the manufacture of converters and other directions, can solve the problems of low effective re-blowing ratio, large resistance, and fast melting loss of magnesia-carbon bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

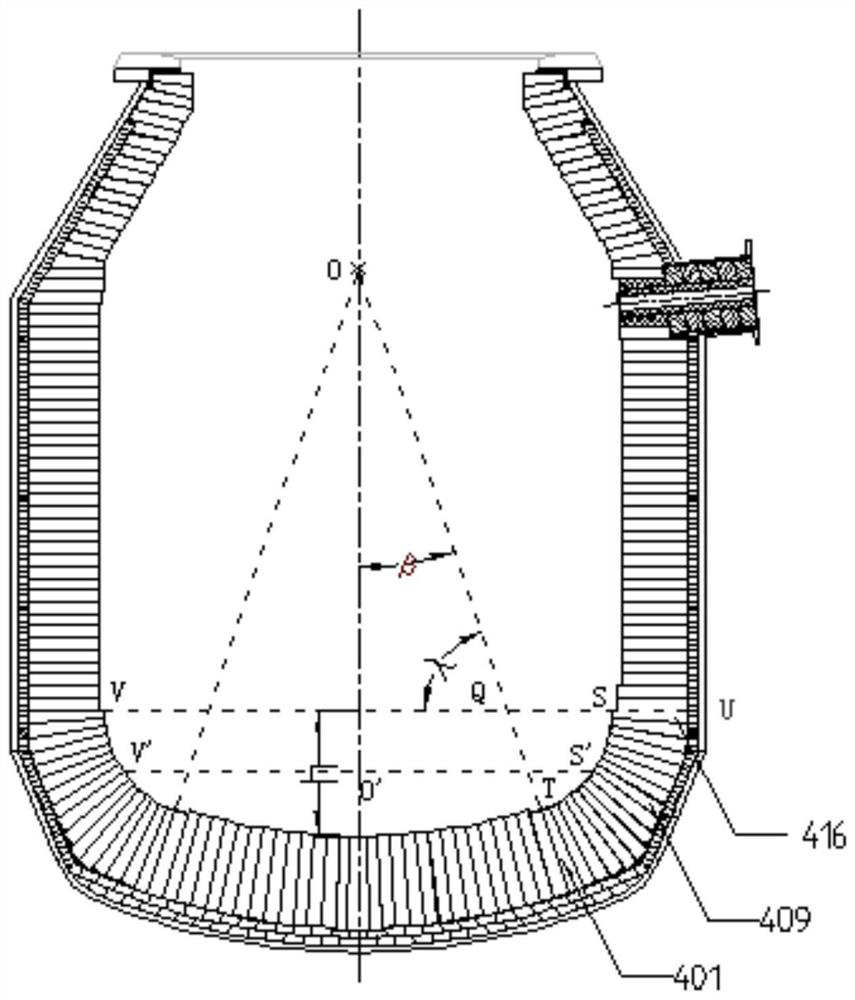

[0060] A 300-ton converter bottom transition brick structure and design example: The converter bottom transition brick 21 is composed of a series of brick types, the uppermost transition brick 416 is attached to the bottom layer of the furnace body brick 27, and the furnace body brick 27 is equipped with a furnace The body permanent layer 26; the transition brick 401, the lowest layer of the transition brick 21 series, is attached to the outer ring of the circular furnace bottom brick 22, and the molten pool permanent layer 25 is set under the side, and the furnace bottom permanent layer 24 is set under the circular furnace bottom brick 22 ; Transition brick 21 and each part assembly of furnace lining see Figure 5 .

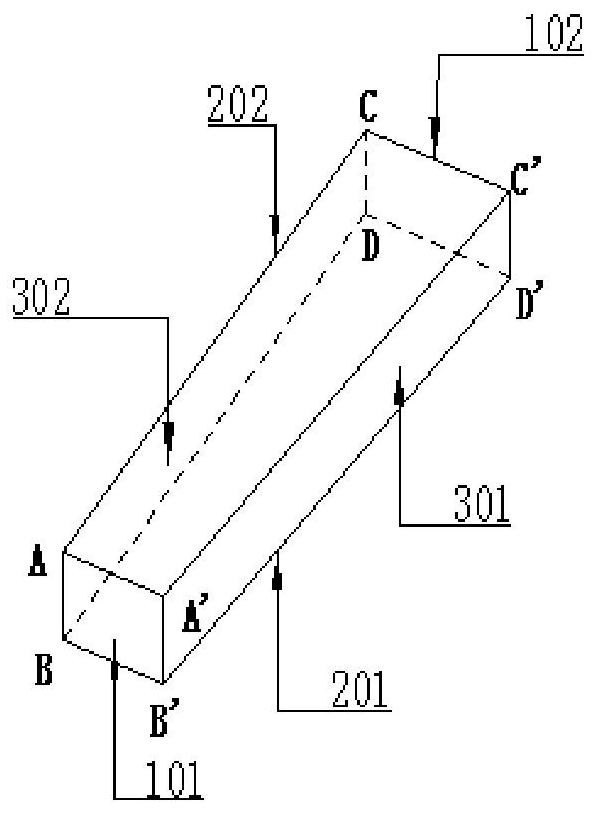

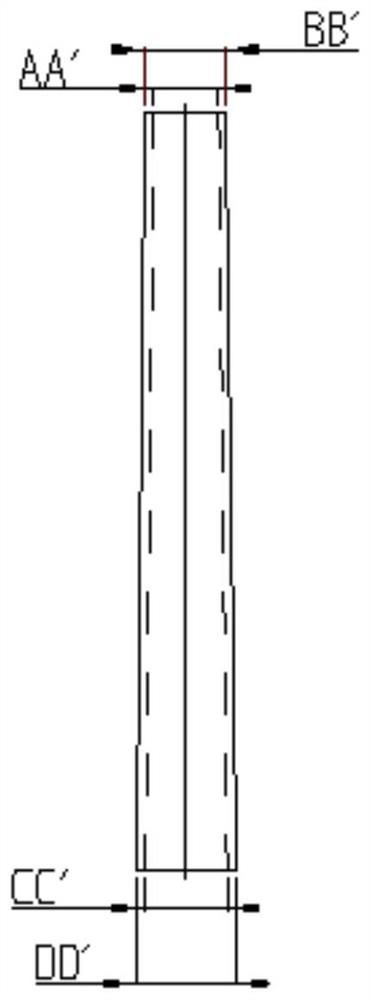

[0061] The transition brick 21 is a radial hexahedron structure, the front end surface 101 and the rear end surface 102 are trapezoidal surfaces or the arc surface AA' direction; the left end surface 202 and the right end surface 201 are both trapezoidal surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com