Construction method for providing shear bearing capacity for gapped discrete steel structure tube bundle

A technology of shear bearing capacity and construction method, applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problem of low shear bearing capacity of horizontal pipe joints and locks between pipe joints, increasing construction difficulty and risk, Extend the construction period and other issues to achieve the effect of solving the problem of shear resistance, simple structure, and avoiding friction and collision of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

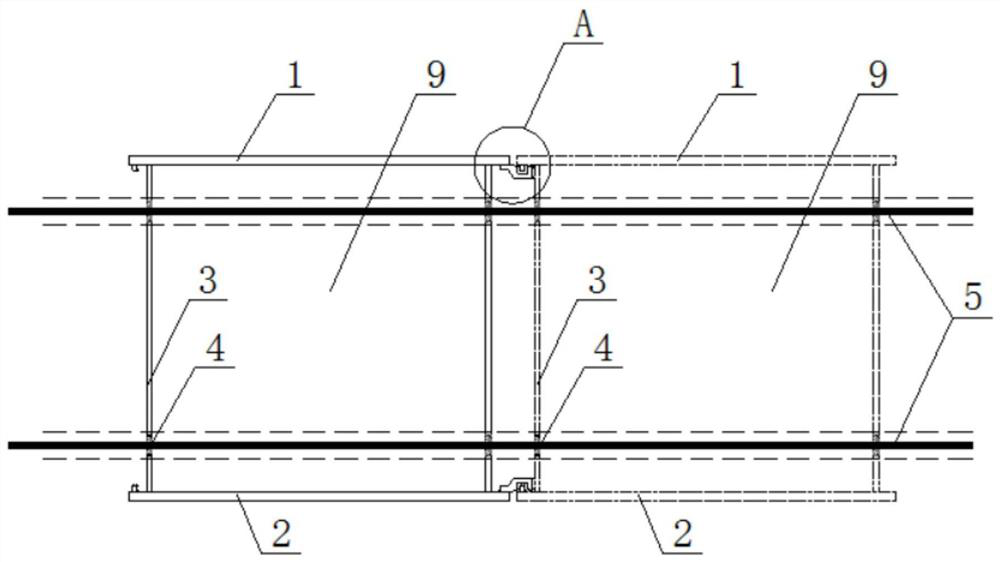

[0031] Such as Figure 1-Figure 2 As shown, a specific embodiment of a construction method for providing shear bearing capacity for discrete steel structure pipe rows with gaps of the present invention includes the following steps:

[0032] Step 1: Complete the manufacture of the outer flange 1 of the steel pipe section, the inner flange 2 of the steel pipe section and the web 3 of the steel pipe section, and set the bellows perforation 4 on the web 3 of the steel pipe section.

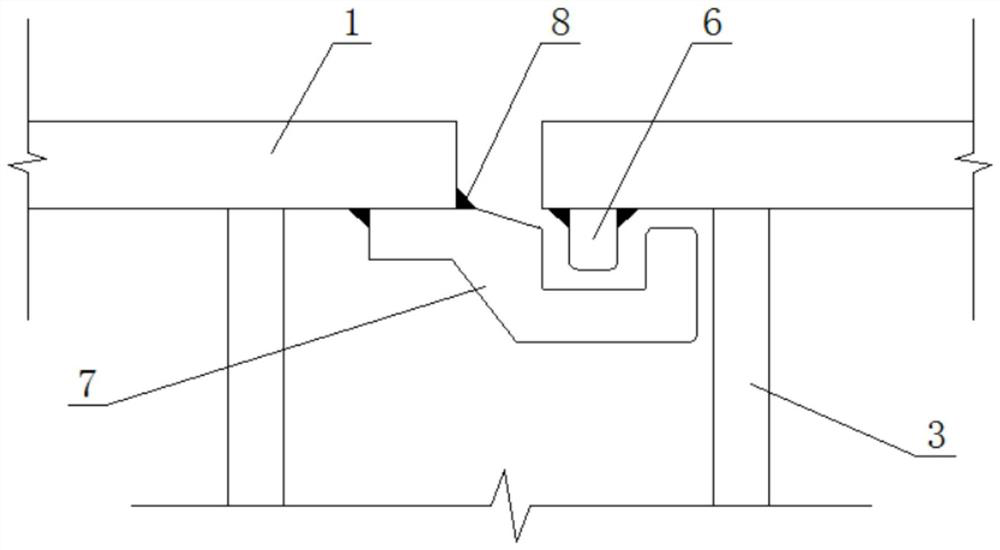

[0033] Step 2: Complete the production of the male clip 6 and the female clip 7, and weld and fix the male clip 6 and the female clip 7 on the outer flange 1 of the steel pipe section and the inner flange 2 of the steel pipe section through fillet welds 9, The male clip 6 and the female clip 7 are arranged along the jacking direction.

[0034] Step 3: Weld the steel pipe section web 3 to the steel pipe section outer flange 1 and the steel pipe section inner flange 2 to complete the entire fabrication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com