Center shaft bowl group structure for electric bicycle

A technology for electric bicycles and group structures, applied in the direction of bearing components, shafts and bearings, vehicle parts, etc., can solve the problems of small rotational friction resistance, bumps on legs and obstacles, etc., and achieve the effect of reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

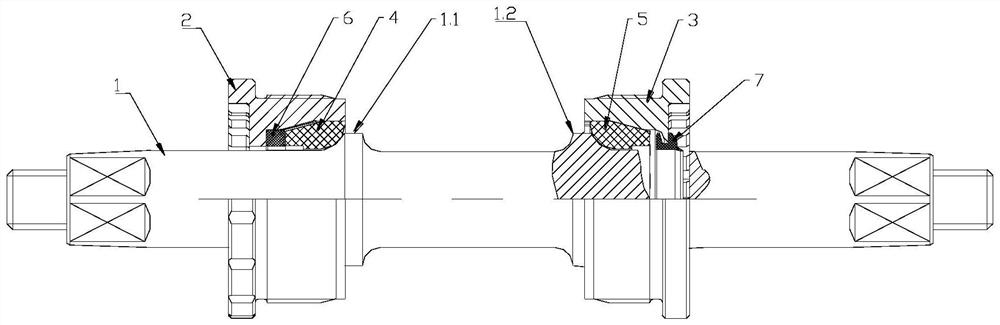

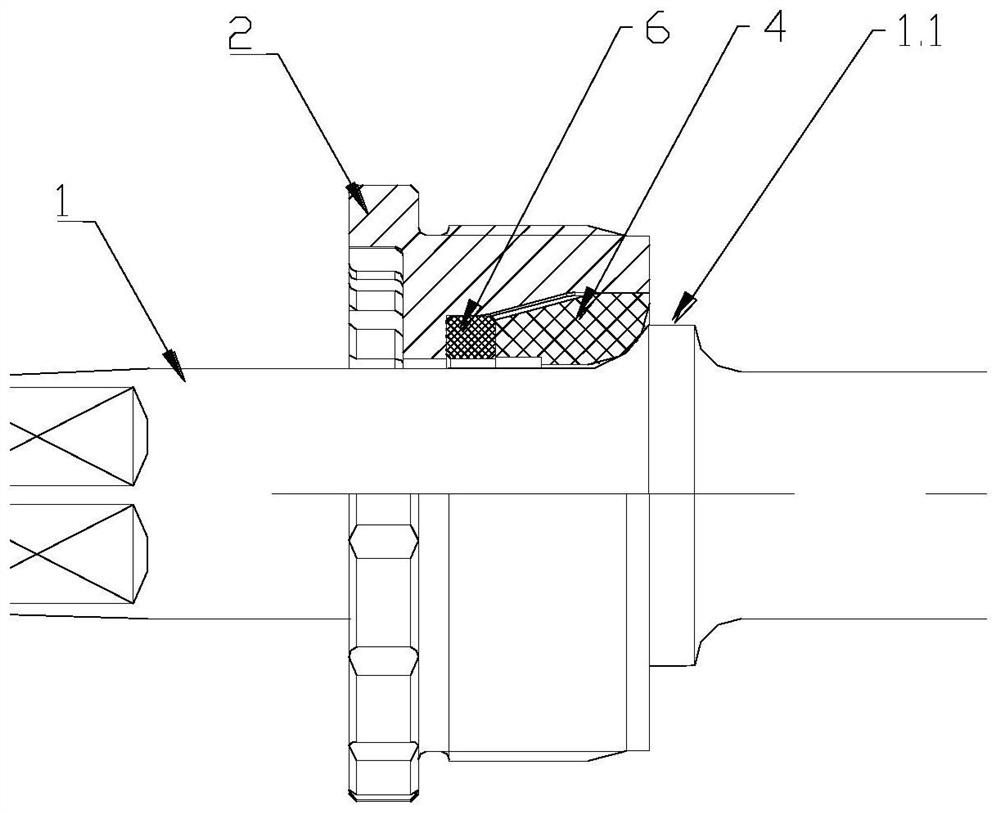

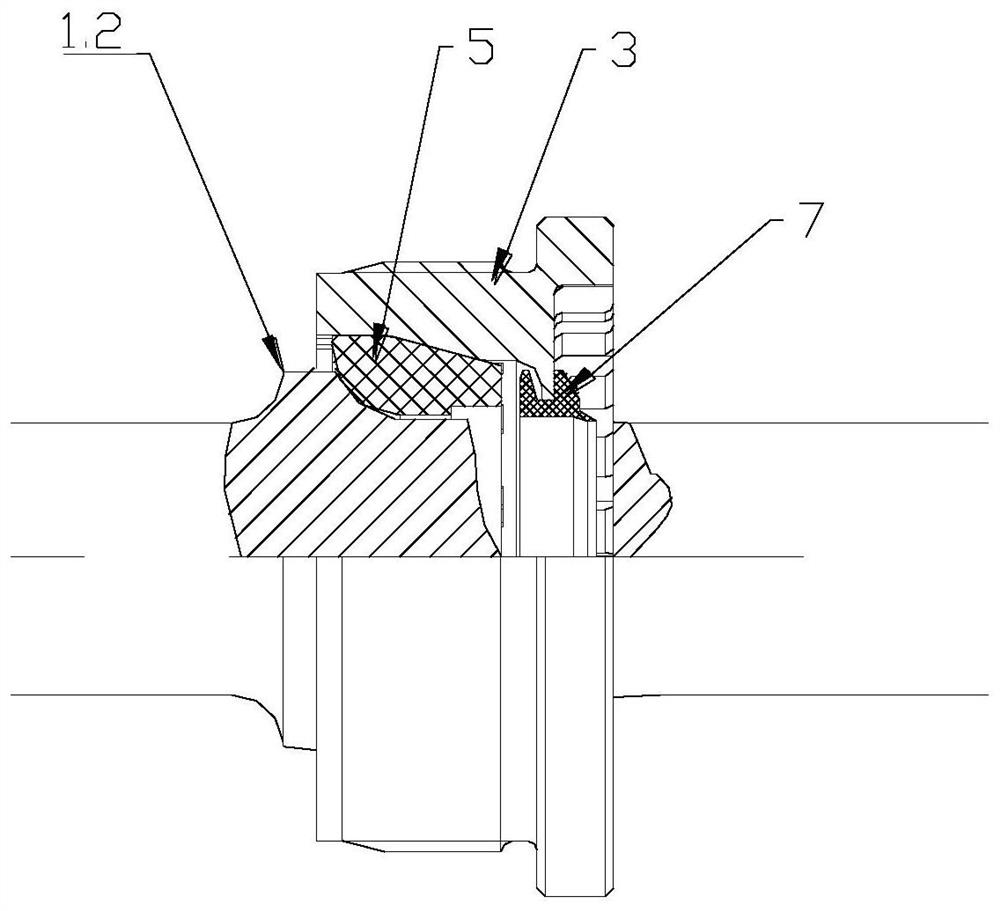

[0032] See attached Figure 1-3 , a center shaft headset structure for an electric bicycle, including a center shaft 1, a positive tooth bowl 2, a negative tooth bowl 3, a first shaft sleeve 4, a second shaft sleeve 5 and a buffer washer 6.

[0033] The central axis 1 is provided with two limiting flanges 1.1 and 1.2, which are arranged along the circumferential direction of the central axis. The height of the limiting flanges is preferably 5-10 mm. Between the two limiting flanges The axial distance is preferably 6-12cm. The outer surface of the limiting flange is an arc-shaped concave structure (the outer surface of the limiting flange refers to the side of the limiting flange facing the outer end of the central axis), and the roughness of the arc-shaped concave surface is preferably 0.4-1.2; The shape of the inner surface of the limiting flange is not limited, and it can be a shape such as a slope or an arc (the inner surface of the limiting flange refers to the side of th...

Embodiment 2

[0040] On the basis of Embodiment 1, further speaking, another buffer washer may be provided at the inner end of the second shaft sleeve to increase the elastic compensation effect.

Embodiment 3

[0042] On the basis of Embodiment 1, further speaking, a sealing ring 7 is provided on the outer end of the orthodontic bowl and / or the inverse tooth bowl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com