Follow-up type device for machining shaft diameter of journal part of crankshaft connecting rod

A crankshaft connecting rod and processing device technology, which is applied in the direction of feeding device, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing balance counterweight, increasing cost of enterprises, large turning radius, etc., and achieves low manufacturing cost and high Machining, the effect of feasible accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

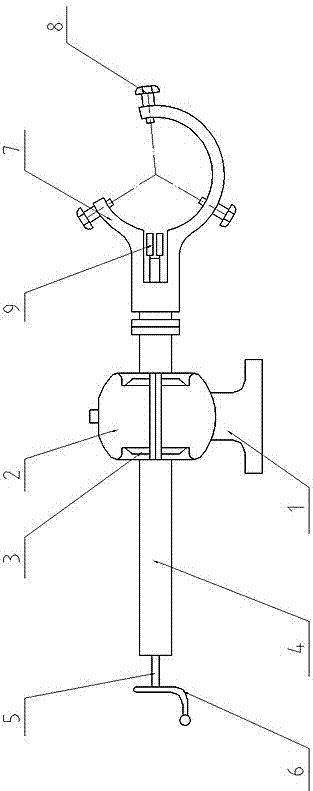

[0008] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: a follow-up type crankshaft connecting rod crank neck part shaft diameter processing device, including a base 1 as a base, an upper cover 2 is buckled on the base 1, and a There is a universal joint bearing 3, a swing sleeve 4 is connected to the universal joint bearing 3, a feed screw 5 is connected to the internal thread of the swing sleeve 4, and a feed handle 6 is also connected to the end of the feed screw 5 , the other end of the swing sleeve 4 is provided with a center frame 7, and three jaws 8 are arranged on this center frame 7, and these three jaws 8 are evenly distributed in the circumferential direction, and each jaw 8 is connected with the center at the same time. The outer walls of the frame 7 are threaded, and a sliding layer is also provided at the inner end of the jaw 8, and a knife rest 9 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com