Vacuum water-cooling rotary joint

A rotary joint, vacuum water cooling technology, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, pipeline heating/cooling, etc., can solve the problem of unused, achieve convenient installation and debugging, solve the follow-up problem, good cooling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, the present invention is further described:

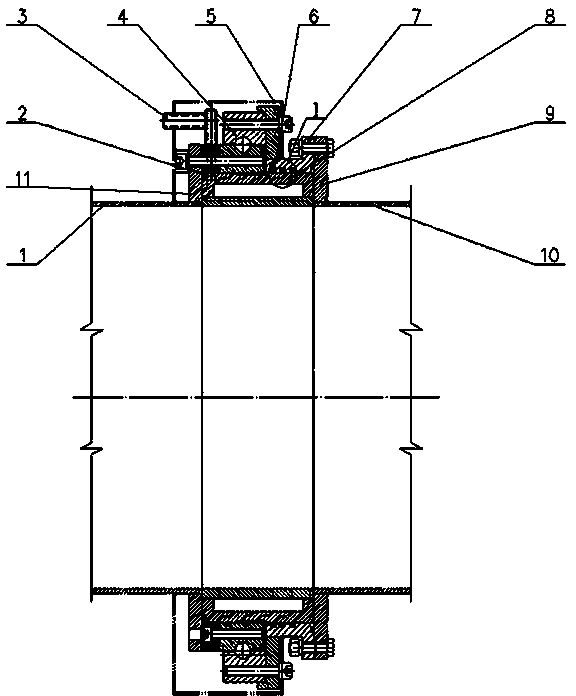

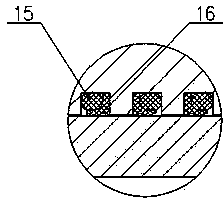

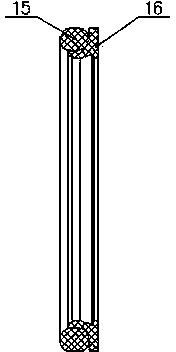

[0030] Such as figure 1 The vacuum water-cooled rotary joint shown includes a left flange 11 and a right flange 9 connected to the vacuum pumping pipe, and a water-cooled core 8 is installed between the two flanges close to the pipe, and the water-cooled core 8 wraps the circumference of the pipe in a ring shape. A cooling water pipe 3 is provided on the water-cooling inner core 8, and an annular slewing bearing 4 is arranged on the outer side of the water-cooling inner core 8. The slewing bearing 4 is divided into two layers, an inner ring and an outer ring, and can rotate with each other. The left flange 11 is provided with There are bolt holes 17, the water-cooling core 8 is connected with the left flange 11 and the inner ring of the slewing bearing 4 through a bolt group, the water-cooling core 8 is also provided with an annular jacket 7, and the jacket 7 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com