Structure fatigue/durability experiment system and method in complex environment

A complex environment and experimental system technology, applied in the field of structural fatigue/durability experimental systems in complex environments, can solve the problem of monotonous loading methods, the inability to realize arbitrary combination and conversion of multiple environmental factors, and the inability to realize ≤-60°C low temperature environment simulation and control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

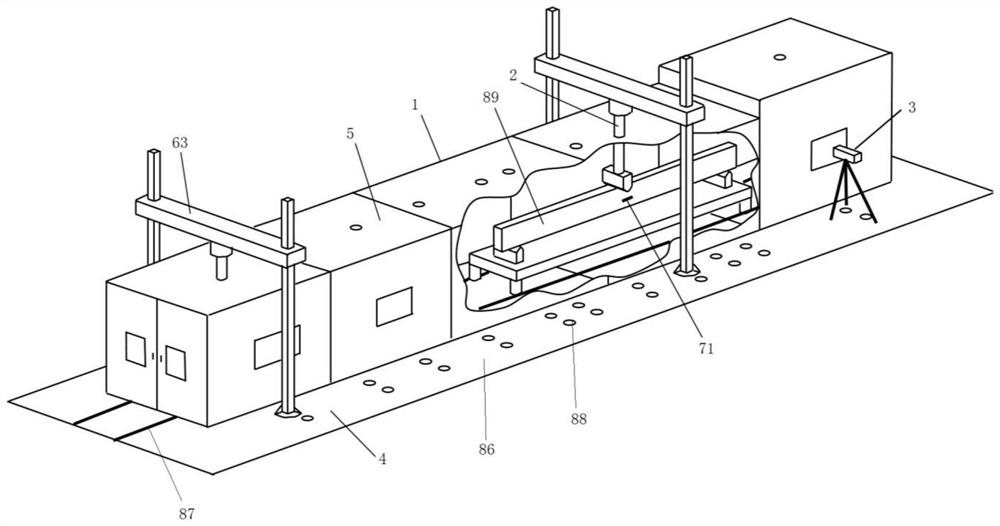

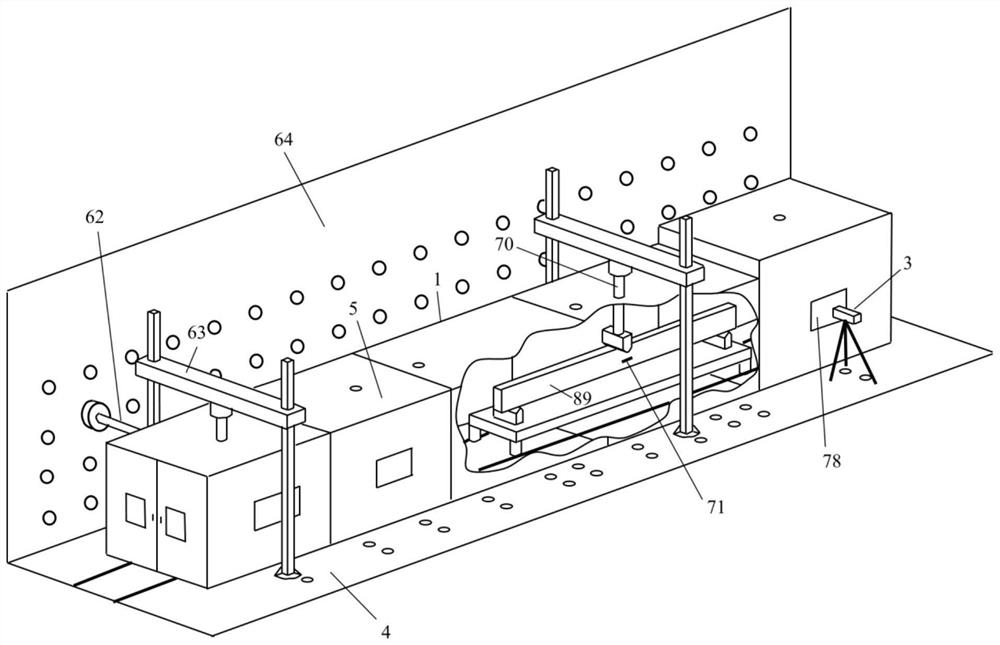

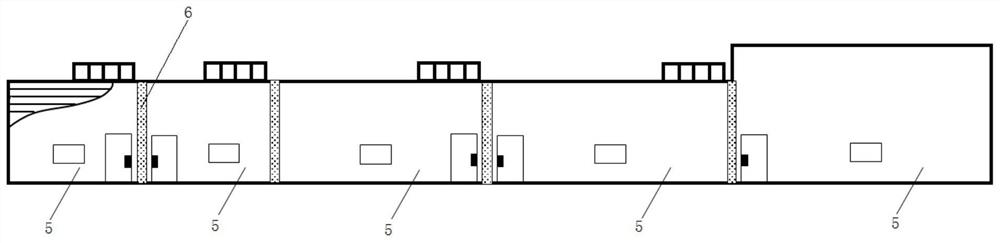

[0066] The present invention will be further described below in conjunction with drawings and embodiments.

[0067] like Figure 1 to Figure 3 The shown structural fatigue / durability experiment system in a complex environment includes an environmental simulation device, a loading device, a testing device, a ground anchor device and a control terminal, and the environmental simulation device, the loading device and the testing device are all connected to the control terminal. The environment simulation device, the loading device and the test device are all arranged on the ground anchor device; the environment simulation device includes at least one test cabin, each test cabin is connected in turn, and a movable partition is provided between adjacent two test cabins; Each test chamber is provided with an independent environment simulation mechanism and a control mechanism, the environment simulation mechanism is connected with the control mechanism, and the control mechanism is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com