Abnormal sound positioning method for electrical equipment

A technology of electrical equipment, positioning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

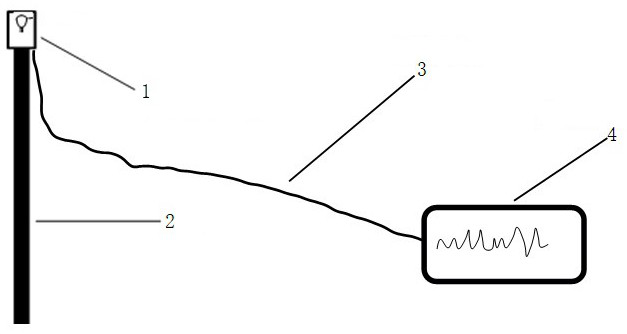

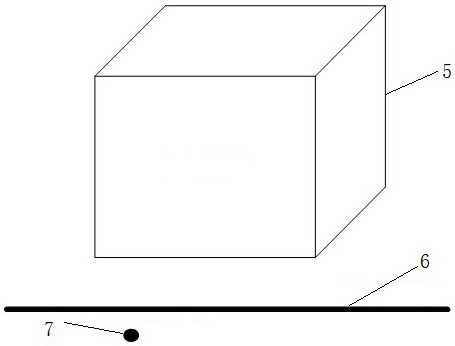

[0031] Such as Figure 1~2 As shown, a method for locating abnormal noise of electrical equipment includes the following steps:

[0032] S1: Fix the sound measuring instrument 1 for measuring the frequency and intensity of a specific sound to one end of the insulating rod 2, so that maintenance personnel can keep a safe distance from the equipment;

[0033] S2: When the abnormal sound of the electrical equipment 5 is heard during the inspection process, use the sound wave detector 4 to measure the sound frequency of the electrical equipment, filter out the abnormal sound frequency and record it as f 0 ;

[0034] S3: On the acoustic wave detector 4, adjust the measurement frequency to f 0 , only measure the intensity of the sound at that frequency;

[0035] S4: The maintenance personnel stand at the measuring point 7 outside the safety distance line 6, hold the insulating rod 2 with the sound measuring instrument 1 fixed on it, bring the sound measuring instrument 1 close to...

Embodiment 2

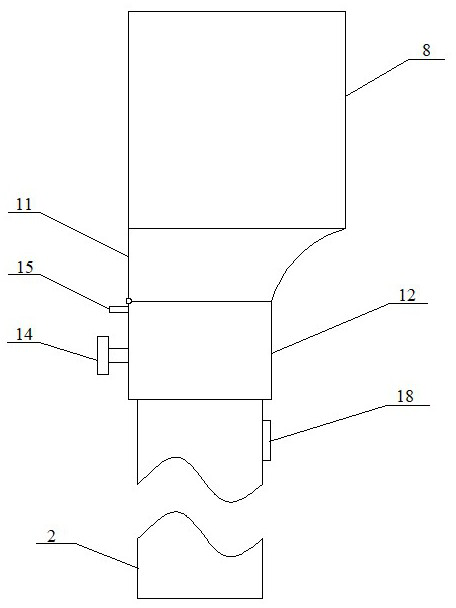

[0040] Such as Figure 3~5 As shown, a method for locating abnormal noise of electrical equipment includes the following steps:

[0041]S1: Fix the sound measuring instrument used to measure the frequency and intensity of a specific sound to one end of the insulating rod so that maintenance personnel can keep a safe distance from the equipment;

[0042] S2: When the abnormal sound of electrical equipment is heard during the inspection process, use a sound wave detector to measure the sound frequency of the electrical equipment, filter out the abnormal sound frequency and record it as f 0 ;

[0043] S3: On the acoustic wave detector, adjust the measurement frequency to f 0 , only measure the intensity of the sound at that frequency;

[0044] S4: The maintenance personnel stand at the measuring point outside the safety distance line, hold the insulating rod with the sound measuring instrument fixed, bring the sound measuring instrument close to the equipment under test, move ...

Embodiment 3

[0052] Such as Figure 6 As shown, the method for locating abnormal noise of electrical equipment in the embodiment of the present invention is different from the second embodiment in that: the control opening and closing part includes a rectangular hanging ring 19 arranged at the bottom of the connecting block 11, and is arranged at the bottom of the connecting block 11. The groove on the top surface of the connecting block two 12, and the pendant arranged in the groove, the pendant is fastened in the rectangular hanging ring.

[0053] The pendant includes a vertical bar 20, a wedge-shaped hanging head 21 and an electric telescopic rod 22. The wedge-shaped hanging head 21 is arranged at the upper end of the vertical bar 20. The top surface of the wedge-shaped hanging head 21 is an arc surface, and the vertical bar 20 The middle part is hinged to the inner walls of both sides of the groove through the shaft body, and the lower end of the vertical rod 20 is flexibly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com