Single-hole capsular retractor and preparation method thereof

A single-porous capsule and hook body technology, which is applied in medical science, intraocular lenses, eye implants, etc., can solve the problems of re-shedding, exposed thread knots, large surgical trauma, etc., and achieve the effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment relates to the preparation method of the single-hole pouch hook of the present invention.

[0070] The preparation method of a kind of single-hole pouch draw hook of the present invention comprises:

[0071] Step S102, bending the suture so that the suture forms an arc-shaped end;

[0072] Step S104, heating the arc-shaped end to shape the arc-shaped end;

[0073] Step S106, heating the first end of the suture so that the first end of the suture forms a blunt end;

[0074]Step S108, clamping the blunt end so that the blunt end forms a round end;

[0075] Step S110 , puncturing the circular end, so that the circular end forms a through hole.

[0076] In step S104, heating the arc-shaped end includes:

[0077] Use a coagulator to cauterize the arc-shaped end for 3-5 seconds.

[0078] In step S106, heating the first end of the suture includes:

[0079] Use a coagulator to cauterize the first end of the suture.

[0080] In step S108, clamping the roun...

Embodiment 2

[0094] This embodiment relates to the single-hole pouch retractor of the present invention, which is made by the preparation method of Embodiment 1.

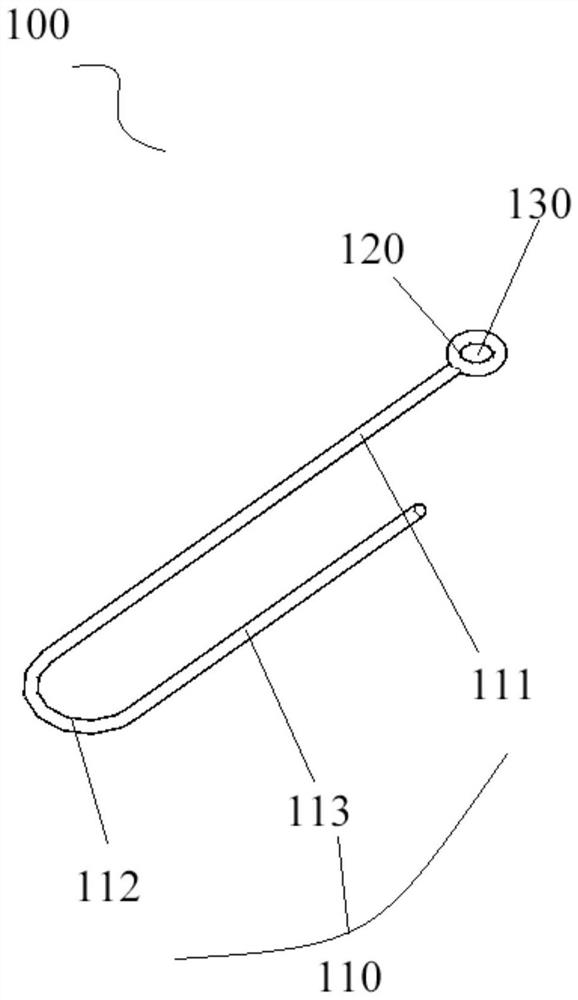

[0095] An exemplary embodiment of the present invention, such as figure 1 As shown, a single-hole pouch pull hook 100 includes a hook body 110 , a connecting end 120 and a through hole 130 , wherein the connecting end 120 is connected to at least one end of the hook body 110 , and the through hole 130 is set through the connecting end 120 .

[0096] Wherein, the single-hole pouch hook 100 is integrally formed.

[0097] Wherein, the single-hole pouch drawer 100 is made of 4-0 polypropylene suture.

[0098] Such as figure 2 As shown, the hook body 110 includes a first hook body 111, a second hook body 112, and a third hook body 113, wherein the hook body 110 is integrally formed, and the first end of the second hook body 112 is connected to the first end of the first hook body 111. The two ends are connected, and the first end...

Embodiment 3

[0125] This embodiment relates to the single-hole pouch retractor device of the present invention, including the single-hole pouch retractor described in Embodiment 2.

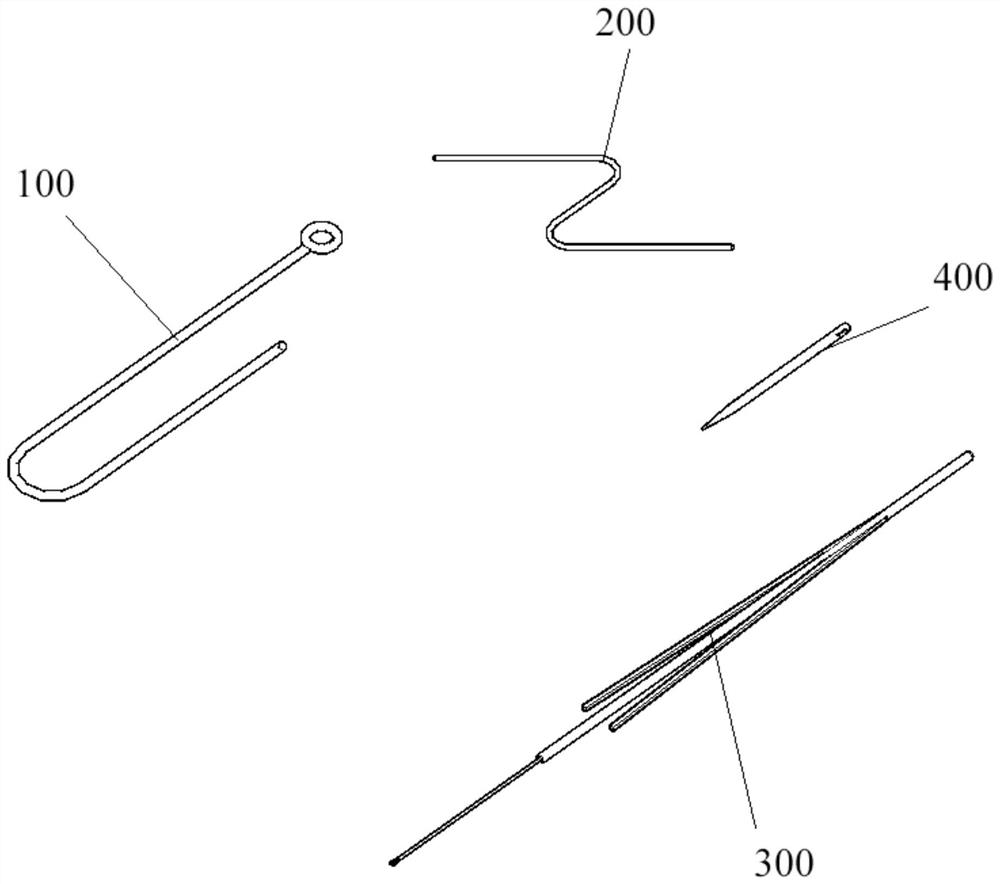

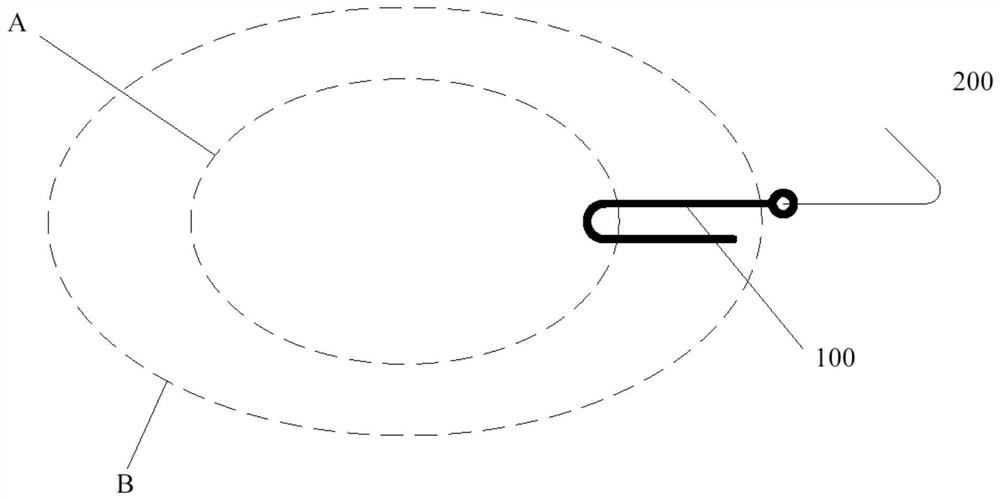

[0126] Such as figure 2 As shown, the single-hole pouch retractor device includes a single-hole pouch retractor 100 , a suture 200 , a threader 300 and a needle 400 .

[0127] The suture 200 is detachably connected to the single-hole pouch hook 100 through the through hole 130 . Specifically, one end of the suture 200 is detachably connected to the hook body 110 after passing through the through hole 130 .

[0128] Wherein, the diameter of the suture 200 is smaller than the diameter of the through hole 130 .

[0129] Wherein, the suture 200 is an 8-0 polypropylene suture.

[0130] The threader 300 is detachably connected with the suture 200 and is used to drive one end of the suture 200 through the through hole 130 .

[0131] Wherein, the threader 300 is medical tweezers.

[0132] In some of these embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com