Matcha grinding device for food processing

A grinding device and food processing technology, applied in application, food science, cocoa, etc., can solve the problems of easy to carry iron blocks, no dust-proof mechanism, and hinder the processing of matcha, and achieve the effect of avoiding moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

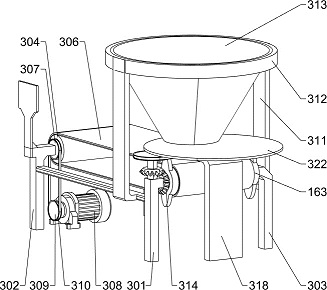

[0032] refer to figure 1 As shown, a matcha grinding device for food processing includes a base frame 1, support legs 2, intermittent feeding mechanism 3 and matcha processing mechanism 4, support legs 2 are installed on both sides of the bottom of the base frame 1, and the base frame 1 An intermittent feeding mechanism 3 is installed on the left side of the top, and a matcha processing mechanism 4 is arranged on the top right side of the bottom frame 1, and the matcha processing mechanism 4 is connected with the intermittent feeding mechanism 3.

[0033] When it is necessary to process matcha, the user pours an appropriate amount of tea into the intermittent feeding mechanism 3, then the user hangs the collection bag on the lower side of the matcha processing mechanism 4, and then the user starts the intermittent feeding mechanism 3 to work, and the intermittent feeding mechanism 3 works The tea leaves can be transported to the matcha processing mechanism 4, and at the same t...

Embodiment 2

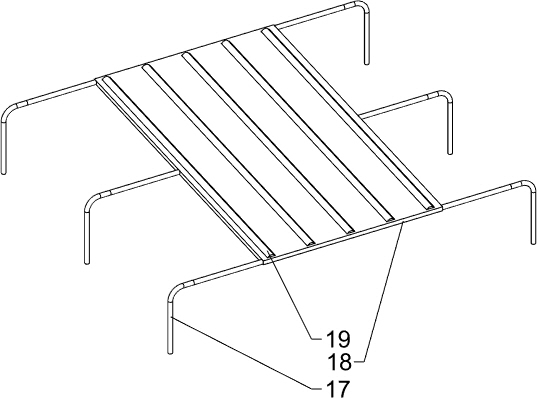

[0035] refer to Figure 2-Figure 4 As shown, on the basis of Embodiment 1, the intermittent feeding mechanism 3 includes a first support 301, a second support 302, a third support 303, a conveying roller 304, a magnetic belt 305, a conveying belt 306, and a first pulley 307 , reduction motor 308, second pulley 309, first belt 310, support frame 311, fixed ring 312, lower hopper 313, first bevel gear 314, first rotating shaft 315, second bevel gear 316, third pulley 317 and blanking parts, the first bracket 301 is installed on the left rear side of the bottom frame 1 top, the bottom frame 1 top on the right side of the first bracket 301 is provided with a second bracket 302, and the front side of the first bracket 301 and the second bracket 302 The top of the bottom frame 1 is provided with a third support 303, between the two adjacent first supports 301 and the third support 303, the conveying roller 304 is rotatably installed, and the two adjacent second supports 302 and the ...

Embodiment 3

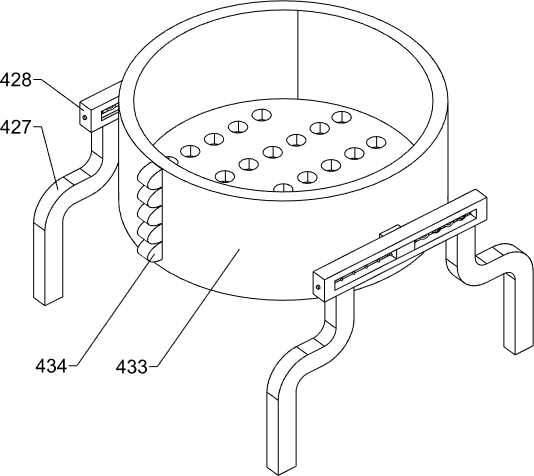

[0040] refer to figure 2 , Figure 5-Figure 9 As shown, on the basis of Embodiment 2, the matcha processing mechanism 4 includes a fixed plate 401, a servo motor 402, a fifth pulley 403, a fifth bracket 404, a spline shaft 405, a sixth pulley 406, a third Belt 407, hydraulic cylinder 408, first mounting plate 409, first support plate 410, second mounting plate 411, bearing 412, spline sleeve 413, lower pressure plate 414, first guide rod 415, grinding disc 416, first Spring 417, contact rod 418 and processing parts, fixed plate 401 is connected on the top of second support 302, and the top of the front side wall of fixed plate 401 is provided with servomotor 402, and the upper end of servomotor 402 output shaft is equipped with fifth pulley 403 , the top right side of the underframe 1 is provided with a fifth bracket 404, the top of the fifth bracket 404 is rotatably installed with a spline shaft 405, the top of the spline shaft 405 is connected with a sixth pulley 406, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com