Method for 4D printing of functionally-gradient titanium-nickel shape memory alloy components

A memory alloy and printing function technology, applied in the direction of additive manufacturing, additive processing, etc., can solve the problem that a single alloy cannot meet local functional requirements, and achieve the effects of reducing oxygen increment, improving accuracy, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, but the present invention should not be limited to the examples.

[0021] What this embodiment adopts is that the titanium-nickel shape memory alloy powder is the pre-alloyed powder of gas atomization, and the content of titanium is 50wt%~55wt%, and the content of nickel is 45wt%~50wt%. The particle size is 20μm~100μm, preferably , with a particle size of 40 μm.

[0022] Specific steps are as follows:

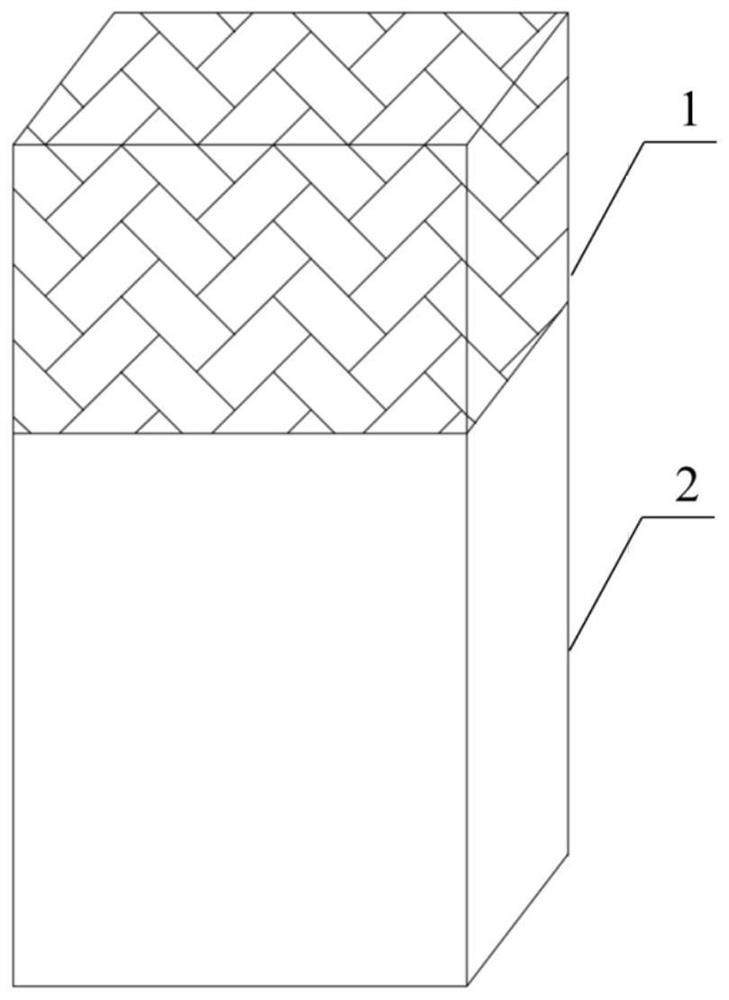

[0023] 1) In this embodiment, Auto CAD software is used to perform three-dimensional modeling on 4D printed functionally graded titanium-nickel shape memory alloy components. Clarify functional divisions, such as figure 1 As shown, it includes a stress-bearing region for bearing compression and tension deformation, and a structural deformation region with superelastic properties and recoverable shape. The 3D model is conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com