A Laser Tailored Welding Method for Thermoformed Steel Sheets with Al-Si Coating

A technology of laser tailor welding and thermoforming, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of reducing production efficiency, time-consuming and laborious, and many processes, so as to improve production efficiency, reduce production costs, and improve mechanics. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

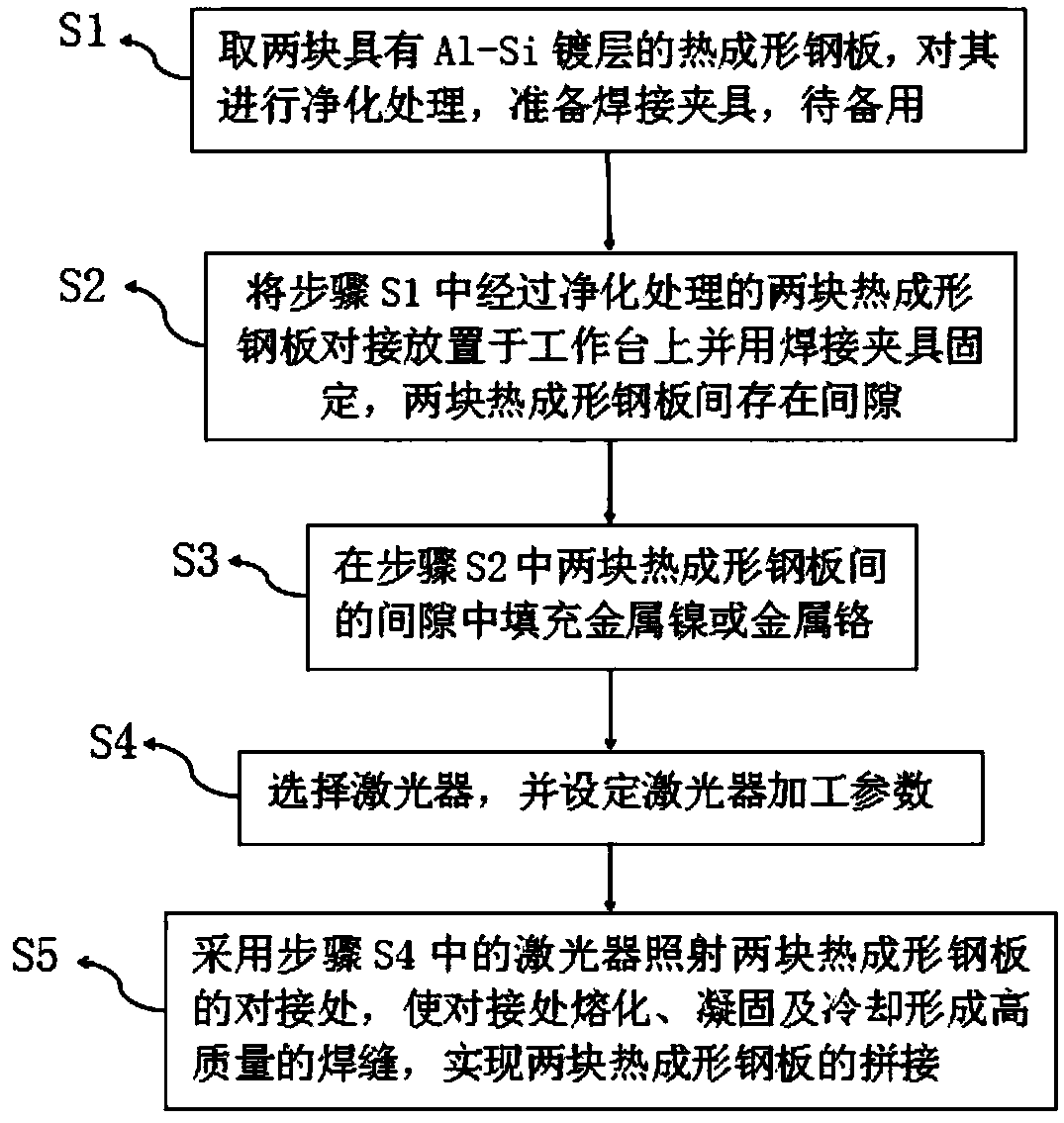

[0041] A laser tailored welding method for a hot formed steel sheet with an Al-Si coating, including the following steps:

[0042] S1. Take two 1.5mm thick hot formed steel plates with Al-Si coating, and the internal microstructure of the hot formed steel plates is lath martensite. Use acetone to clean the surface of the two hot formed steel plates with oil stains, then cool and air dry, prepare welding fixtures for use.

[0043] S2. Place the two hot-formed steel plates that have undergone the purification treatment in step S1 on the workbench butt and fix them with a welding fixture. There is a gap between the two hot-formed steel plates, and the gap distance is 0.03 mm.

[0044] S3. Fill the gap between the two hot formed steel plates in step S2 with nickel foil. The thickness of the filled nickel foil is 0.03mm, and the length and width are the same as the dimensions of the hot formed steel sheet.

[0045] S4. Choose to use fiber laser and set laser processing parameters: laser p...

Embodiment 2

[0050] The difference between this embodiment and the first embodiment is that the thickness of the two hot formed steel plates with Al-Si coating is 2.0 mm, and the gap distance between the two is 0.5 mm. A wire feeder is used to feed a 0.5mm diameter chromium wire into the gap between two hot formed steel plates, and the wire feeding speed is 3m·min -1 . The laser processing parameters are set as: laser power 3000W, laser scanning speed 3m·min -1 , The laser spot diameter is 0.05mm.

[0051] Similarly, using the same laser processing parameters, but without adding chromium wire directly for tailor welding, the microstructure of the welded joint is δ ferrite and lath martensite, and the measured tensile strength is only 790MPa. The location appears in the fusion zone.

[0052] Using the tailor-welding method in this embodiment, after adding chromium wire, the microstructure of the welded joint obtained by tailor-welding is pure martensite, and the measured tensile strength can re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com