Welding method, system and readable medium for longitudinally welded pipe

A technology of straight seam welded pipe and welding method, which is applied in the field of welded pipe welding and welding, to achieve the effects of ensuring welding quality, avoiding errors, and convenient selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

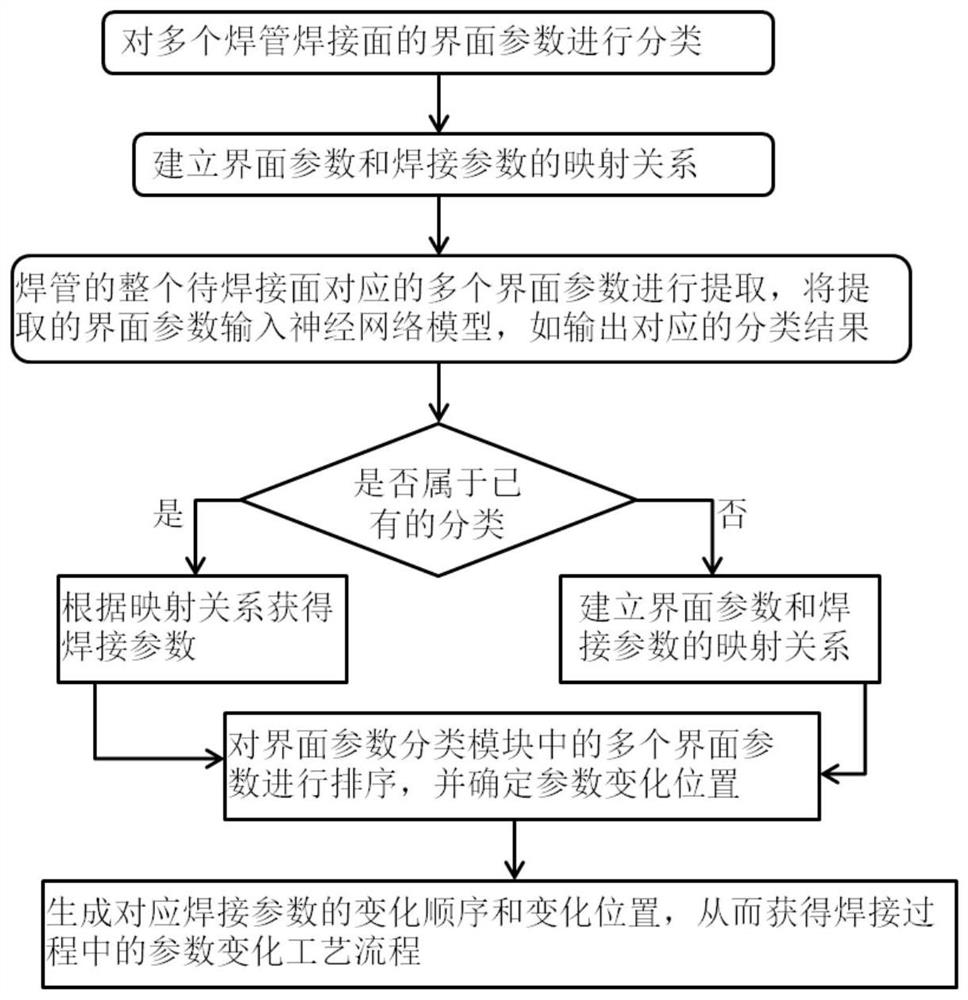

[0032] This embodiment discloses a welding method for a straight seam welded pipe, such as figure 1 shown, including the following steps:

[0033] 1) Input the obtained interface parameters of the welding surfaces of multiple welded pipes into the neural network model, and train them to obtain classification results.

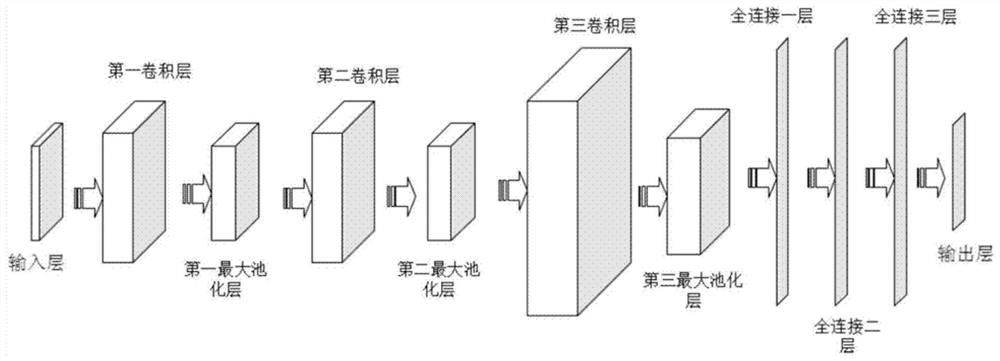

[0034]like figure 2 As shown, the network layers of the neural network model include the first convolutional layer, the first maximum pooling layer, the second convolutional layer, the second maximum pooling layer, the third convolutional layer and the third maximum pooling layer. The fully connected layer of the network model includes three fully connected layers. The size of the convolution kernel of the first convolutional layer is 3x3, the number is 256, and the step size is 2; the window size of the first maximum pooling layer is 3x3, and the step size is 2. The length is 2; the convolution kernel size of the second convolutional layer is 3x3, the number...

Embodiment 2

[0055] Based on the same inventive concept, the present embodiment discloses a welding system for a straight seam welded pipe, including:

[0056] The model training module is used to input the obtained interface parameters of multiple welded pipe welding surfaces into the neural network model, and train it to obtain classification results;

[0057] The mapping module is used to obtain welding parameters corresponding to each classification result, establish a corresponding mapping relationship between each classification result and its corresponding welding parameters, and form a mapping relationship library;

[0058] The interface parameter classification module is used to extract multiple interface parameters corresponding to the entire surface to be welded of the welded pipe, and input the extracted interface parameters into the neural network model. If the corresponding classification result is output, the welding parameters are obtained according to the mapping relationsh...

Embodiment 3

[0063] Based on the same inventive concept, the present embodiment discloses a computer-readable storage medium storing one or more programs, wherein the one or more programs include instructions, and the instructions, when executed by a computing device, cause the computing device to execute any one of the above-mentioned programs. The welding method of the straight seam welded pipe of the item.

[0064] As will be appreciated by those skilled in the art, the embodiments of the present application may be provided as a method, a system, or a computer program product. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage media (including, but not limited to, disk storage, CD-ROM, optical storage, etc.) having computer-usa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com