Roller clamping type bamboo tube slicer

A clamping and slicer technology, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of time-consuming and laborious, large error of bamboo slice size, low efficiency, etc., and achieve the effect of simple adjustment of control program and convenient slicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

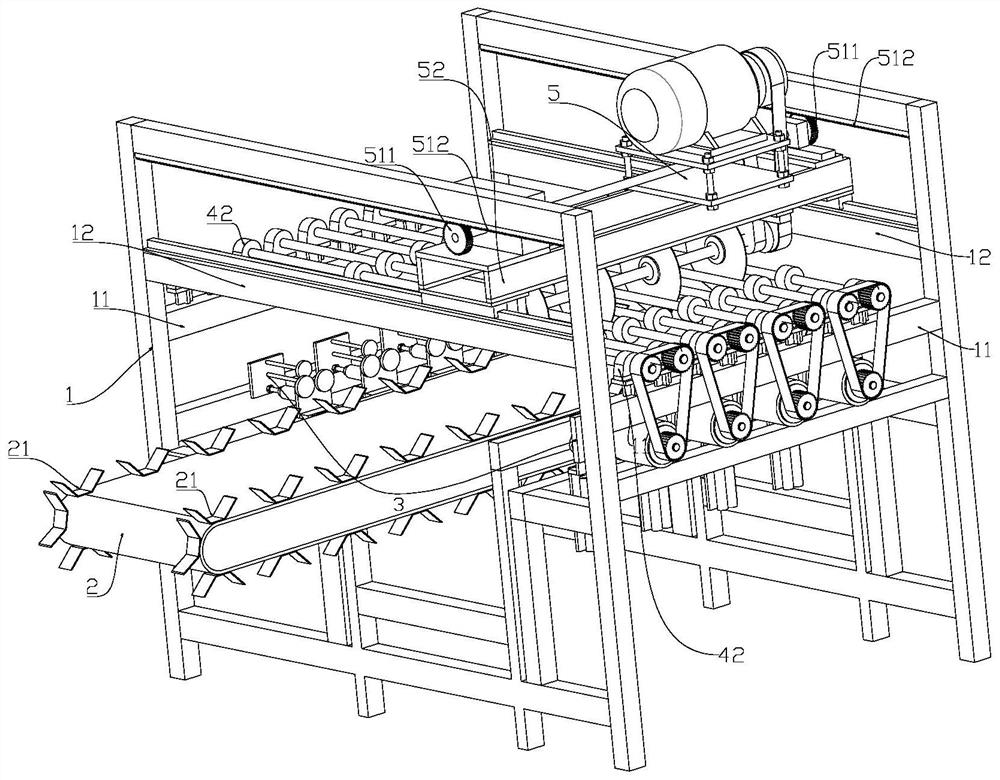

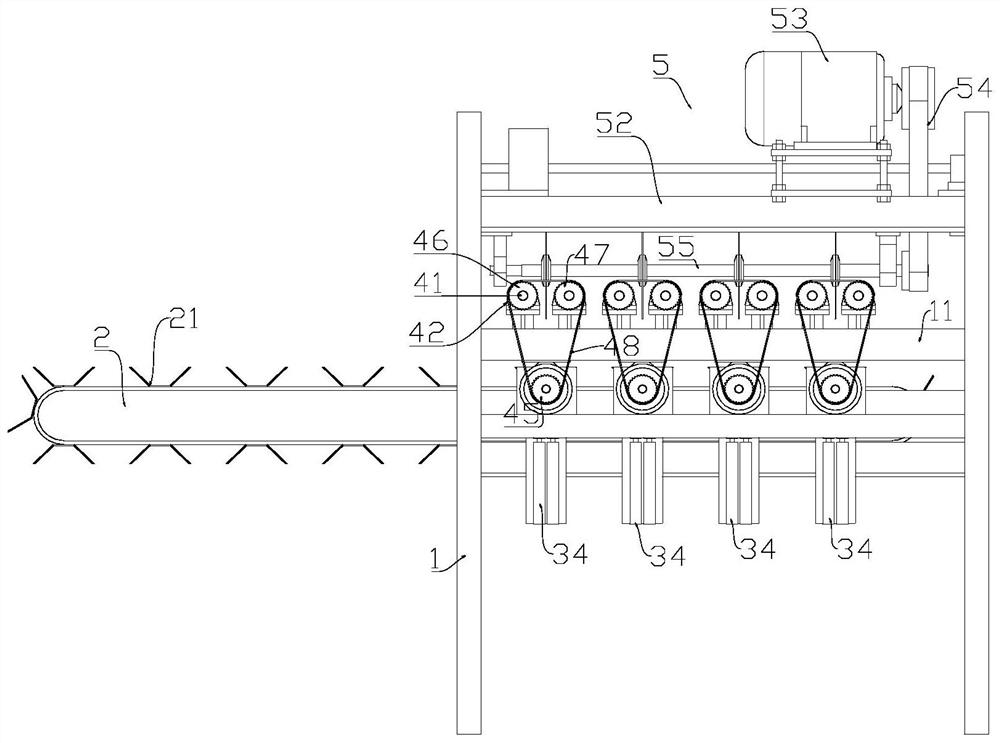

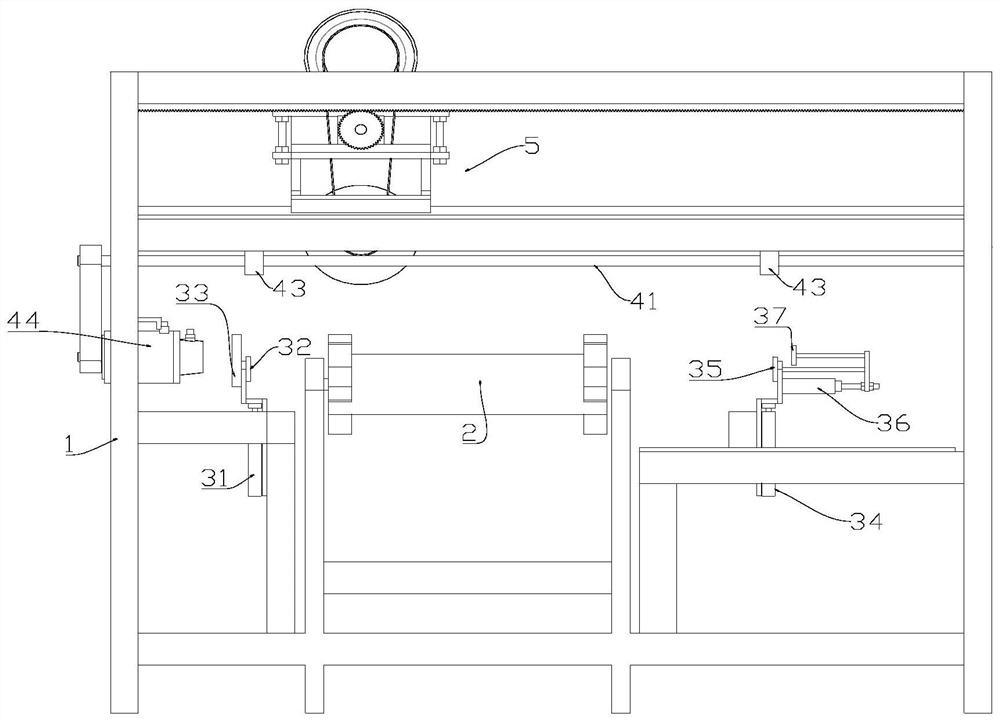

[0030] see Figure 1-5A kind of roller clamping type bamboo tube opening machine, comprising frame 1, conveying device 2, clamping device, cutting device 5 and controller, conveying device 2 is arranged on frame 1, and conveying device 2 is positioned at frame 1. In the middle of the front and rear directions, the transmission device 2 transmits the bamboo tube from left to right. The transmission device 2 is provided with a plurality of evenly distributed support frame groups. The bamboo tube is placed on the support frame group 21, and the bamboo tube is transmitted through the support frame group 21. There is at least one device, and when there are more than two clamping devices, the distance between adjacent support frame groups is the same as the distance between adjacent clamping devices. Specifically, there are four clamping devices, and the four clamping devices are transported along the The conveying direction of the device 2 (that is, from left to right) is evenly ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com