Novel wide-body mining hydro-pneumatic suspension double-vehicle rear axle device capable of avoiding loading difficulty

A new type of oil-air suspension technology, which is applied to axles, wheels, vehicle components, etc., can solve the problems of insufficient bearing capacity and fracture of the suspension system and the rear axle housing, so as to avoid heat attenuation, increase the outer diameter, and avoid affecting the use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

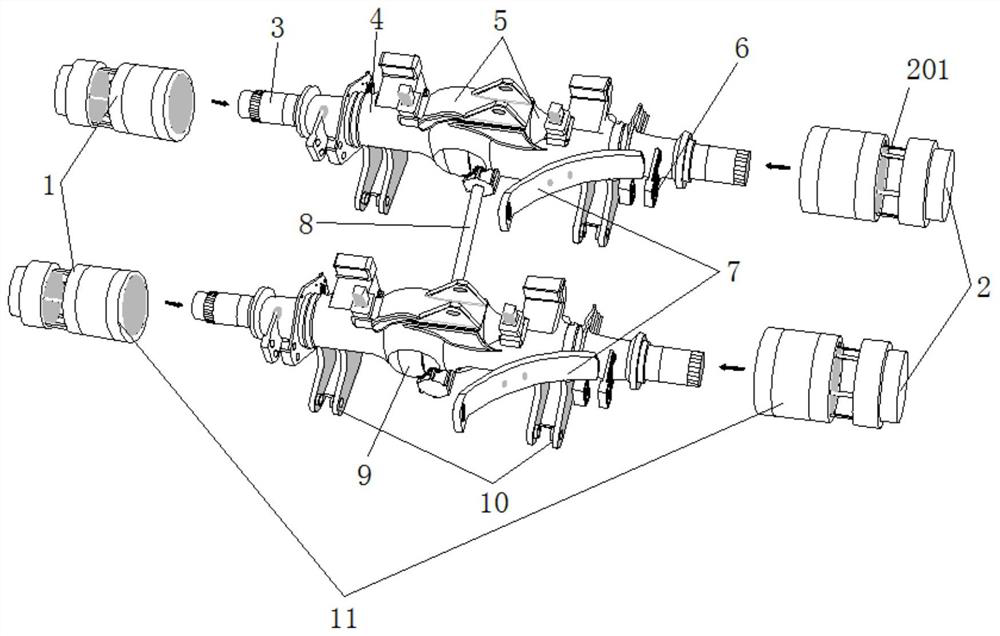

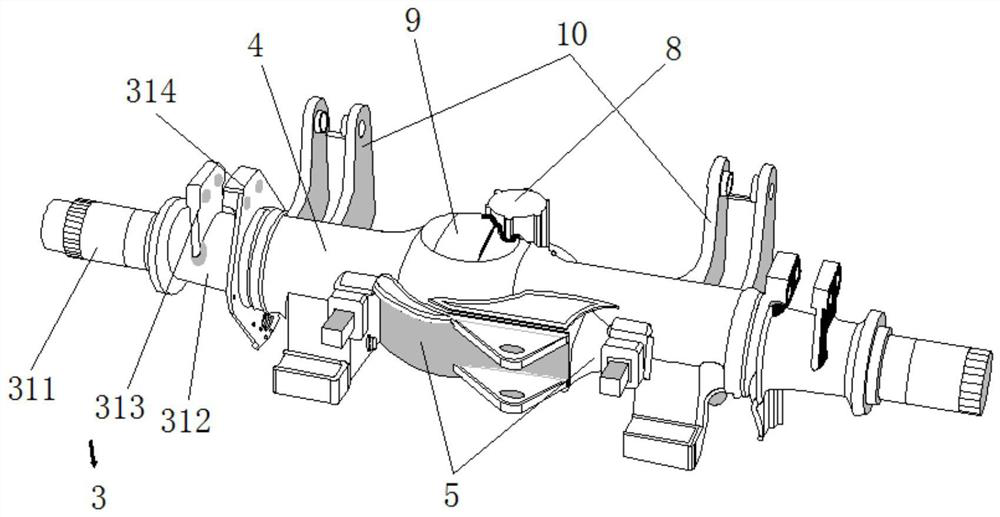

[0025] see Figure 1-2 , a new type of wide-body mining oil-gas suspension double-vehicle rear axle device for avoiding load difficulties, including a hub 1, the outer wall of the hub 1 is connected with a casing 11, the inner wall of the casing 11 is connected with a runner 2, and the casing The inner side wall of 11 is slidingly connected with a connecting mechanism 3, the inside of the connecting mechanism 3 includes a connecting column 311, the outer side wall of the connecting column 311 is connected with a butt joint 312, and the outer side wall of the butt joint 312 is connected with a butt plate 313. The docking frame 314, the end of the connecting mechanism 3 away from the shell 11 is connected with the main column 4, the outer wall of the main column 4 is connected with the main bridge mechanism 5, and the side wall of the main column 4 is connected with the buckle 6, The side wall of the buckle 6 is clamped with an A-shaped frame 7 , the side wall of the main body c...

Embodiment 2

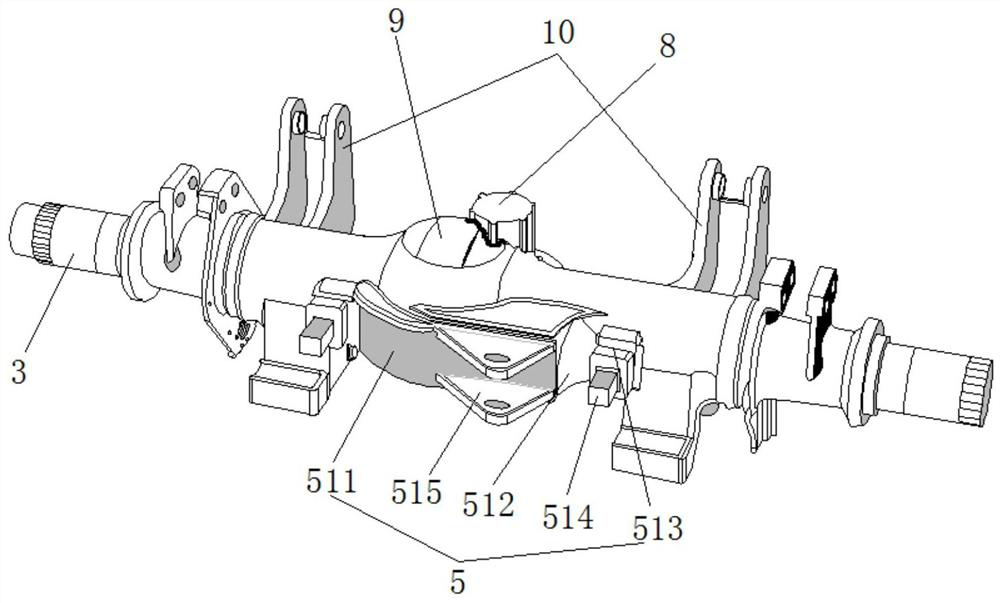

[0032] see figure 1 with image 3 , a new type of wide-body mining oil-gas suspension double-vehicle rear axle device for avoiding load difficulties, including a hub 1, the outer wall of the hub 1 is connected with a casing 11, the inner wall of the casing 11 is connected with a runner 2, and the casing The inner side wall of 11 is slidingly connected with a connecting mechanism 3, and the end of the connecting mechanism 3 away from the shell 11 is penetrated and connected with the main column 4, and the outer wall of the main column 4 is connected with the main bridge mechanism 5, and the inside of the main bridge mechanism 5 is penetrated. Connected with a rear axle 511, the rear end of the side wall of the rear axle 511 is connected with a bridge pipe 512, and the end of the bridge pipe 512 away from the rear axle 511 is connected with a movable frame 513, and the inside of the movable frame 513 is slidably connected with a movable plug 514. The side wall of the bridge 511...

Embodiment 3

[0039] see Figure 1-4 , a new type of wide-body mining oil-gas suspension double-vehicle rear axle device for avoiding load difficulties, including a hub 1, the outer wall of the hub 1 is connected with a casing 11, the inner wall of the casing 11 is connected with a runner 2, and the casing The inner side wall of 11 is slidingly connected with a connecting mechanism 3, the inside of the connecting mechanism 3 includes a connecting column 311, the outer side wall of the connecting column 311 is connected with a butt joint 312, and the outer side wall of the butt joint 312 is connected with a butt plate 313, the docking frame 314, the end of the connection mechanism 3 away from the shell 11 is connected with the main column 4, the outer wall of the main column 4 is connected with the main bridge mechanism 5, and the inside of the main bridge mechanism 5 is connected with the rear bridge 511. The rear end of the side wall of the bridge 511 is connected with a bridge tube 512, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com